Cross-scale two-dimensional large-stroke high-speed and high-precision motion platform

A technology of motion platform and large stroke, which is applied in the direction of using feedback control, etc., can solve the problem that large stroke and high positioning accuracy cannot be taken into account at the same time, and achieve the effect of simple structure, high positioning accuracy and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

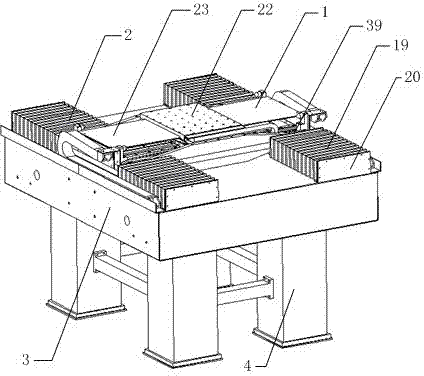

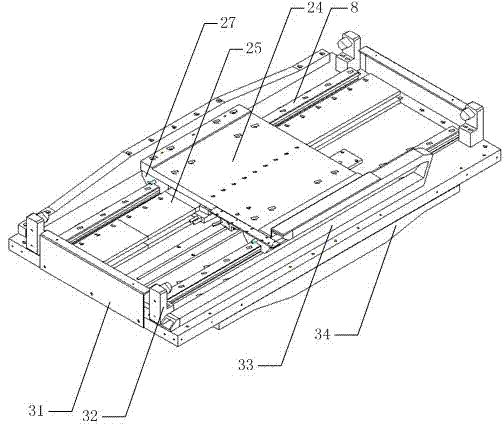

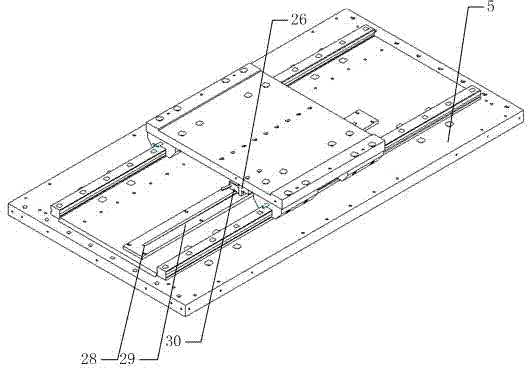

[0020] Such as figure 1 and Figure 6 As shown, a cross-scale two-dimensional large-stroke high-speed and high-precision motion platform includes an upper Y-direction workbench 1, a lower X-direction bilateral drive workbench 2, a marble platform 3 and a bracket 4, and the upper Y-direction workbench 1 is connected in series with the lower X-direction bilateral drive table 2 and placed on the marble platform 3; the upper Y-direction workbench 1 is driven by a Y-direction linear motor 25, guided by two Y-direction high-speed rolling linear guide rails 8, And through a Y-direction grating ruler 28 to complete the Y-direction position feedback; the upper Y-direction workbench 1 is fixed on the lower X-direction bilateral drive workbench 2 through the XY adapter plate 5; the lower X-direction bilateral drive workbench 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com