Small-diameter solid core polarization-maintaining photonic crystal fiber of four-layer structure

A photonic crystal fiber, layer structure technology, applied in the direction of multi-layer core/cladding fiber, cladding fiber, light guide, etc., can solve the problems of inability to meet the use of miniaturized gyroscope, large diameter of cladding and coating, etc. Achieve the effect of being conducive to miniaturization, improving gyro accuracy, and reducing fiber size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

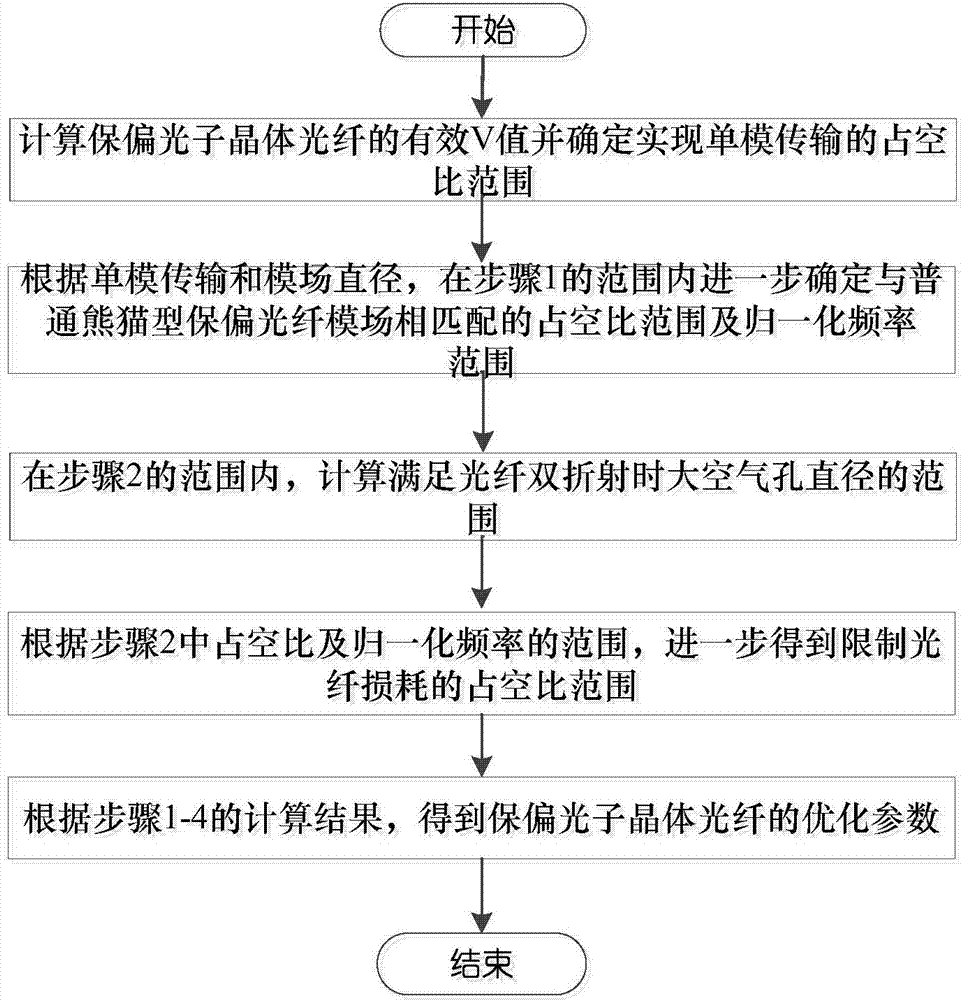

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0062] In order to improve the accuracy of the fiber optic gyroscope, the diameter of the cladding and coating layer of the fiber is reduced under a certain size and volume. Therefore, in order to meet the strength requirements in the use of the fiber, the number of air hole layers must be reduced and the structure of the fiber must be redesigned.

[0063] A thin-diameter solid-core polarization-maintaining photonic crystal fiber with a four-layer structure, such as figure 1 As shown, the cross section is circular, and the structure from the outside to the inside is the coating layer 1, the cladding layer 2 and the cladding air hole 3; the photonic crystal fiber is preferably produced by the stack and draw method.

[0064] Wherein the diameter of the coating layer 1 is preferably 135 μm, and the diameter of the cladding layer 2 is preferably 80 μm-100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com