Residual magnetism flaw detection method and device for piston rings based on series-connection closed type magnetization

A flaw detection device and piston ring technology, applied in the direction of material magnetic variables, etc., can solve the problems of difficulty in realizing one-time overall magnetization of the piston ring, difficult relative movement of detection probes, and complicated external connections, so as to avoid space magnetic field interference and reduce detection. The effect of high blind spot and defect detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and example the present invention is described in further detail:

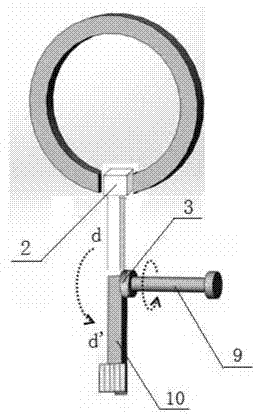

[0044] Such as figure 1 The split piston ring shown has different specifications and sizes, irregular cross-sectional shape, small thickness and width, and small common defects. use figure 1 In the series closed magnetization method shown, the permanent magnet 2 is connected in series to the opening gap of the piston ring 1, its N pole is attached to one end of the opening of the piston ring 1, and the S pole is attached to the other end of the opening of the piston ring 1 to form a complete Closed ring magnetic circuit for penetrating and uniform magnetization of the piston rings to the required strength.

[0045] According to the size of the specific piston ring 1 opening gap, adopt figure 2 The N and S poles of the plurality of sheet permanent magnets 2' are stacked in series to adjust the total thickness of the permanent magnets in the effective dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com