Vehicle lamp air tightness detection system

An air-tightness detection and air-tightness technology, which is applied in the direction of using liquid/vacuum degree for liquid-tightness measurement and measuring the fluid's acceleration and deceleration rate, etc., can solve the problems of insufficient environmental protection, increased investment and cost, and insufficient economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

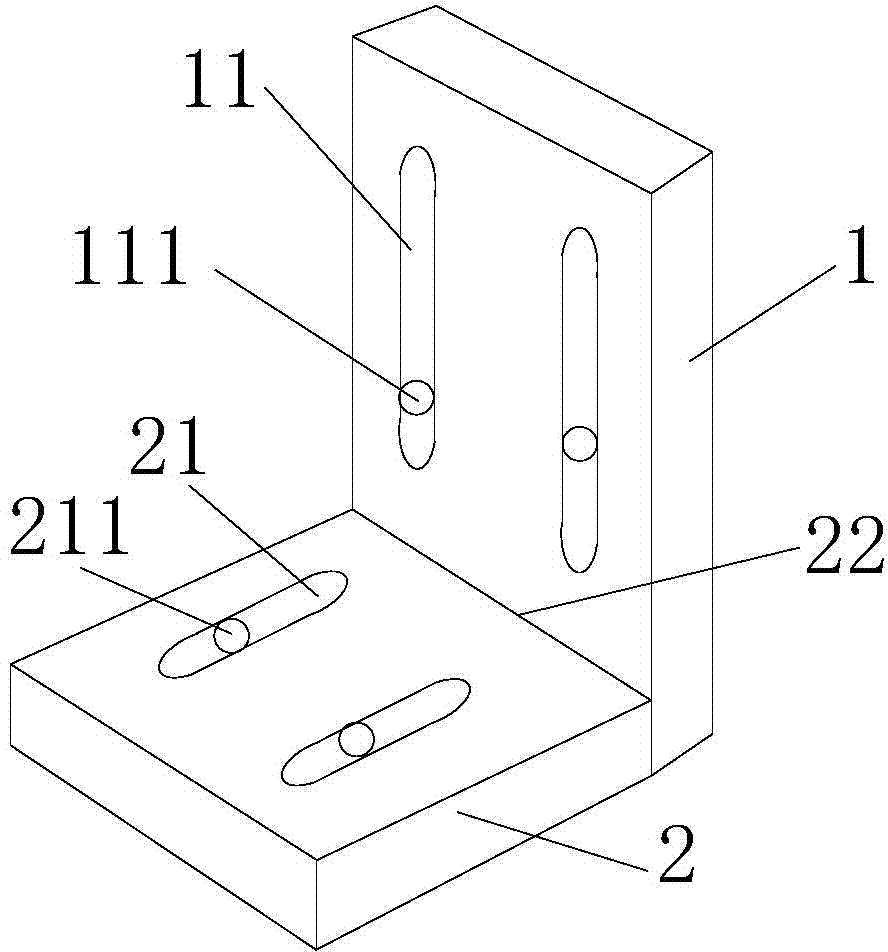

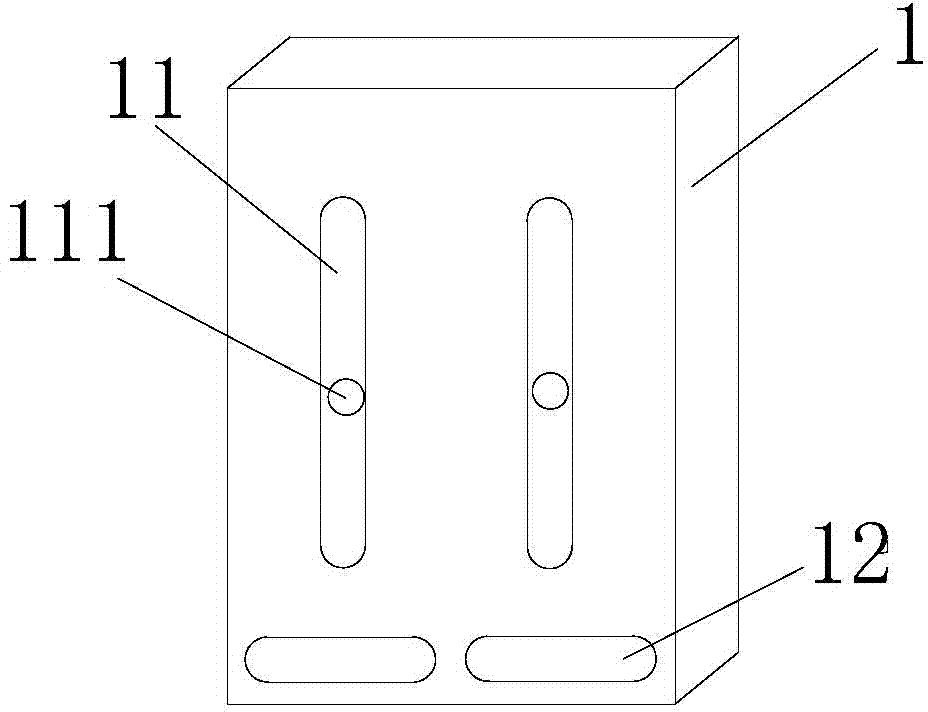

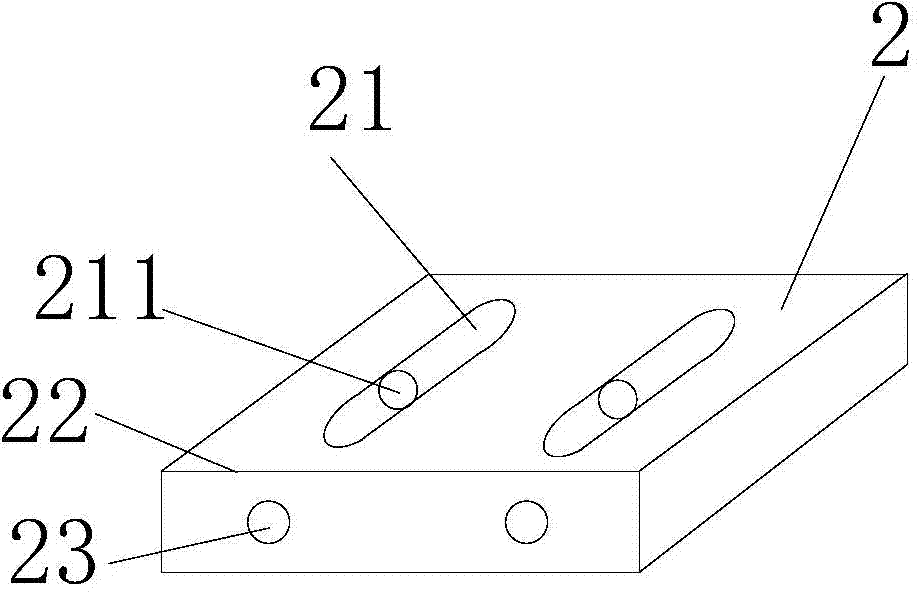

[0031] Referring to the accompanying drawings, the vehicle lamp air tightness detection system includes an air tightness detection machine and a fixing device for positioning the vehicle light;

[0032] The air tightness testing machine includes an air inlet gun 5 and a pressure gauge 6, the air inlet gun 5 communicates with the air inlet of the vehicle lamp, the pressure gauge 6 communicates with the pressure measuring port of the vehicle lamp, and the The pressure measuring device 6 is provided with a sensor for measuring the air pressure value in the lamp, and the sensor is connected to a controller with a pre-stored maximum value of the air pressure difference. The controller is located in the air tightness detector, and the controller The output terminal of the sensor is connected with the display device and the warning device, and the sensor transmits the air pressure information in the lamp to the controller, and the controller controls the display device and the warning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com