Ultrasonic multi-channel self-reaction chemical coating instrument

An electroless coating, multi-channel technology, applied in liquid electroless plating, metal material coating process, coating and other directions, can solve the problem of small amount of digested sample, and achieve the goal of ensuring uniformity, improving reaction efficiency, and ensuring uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

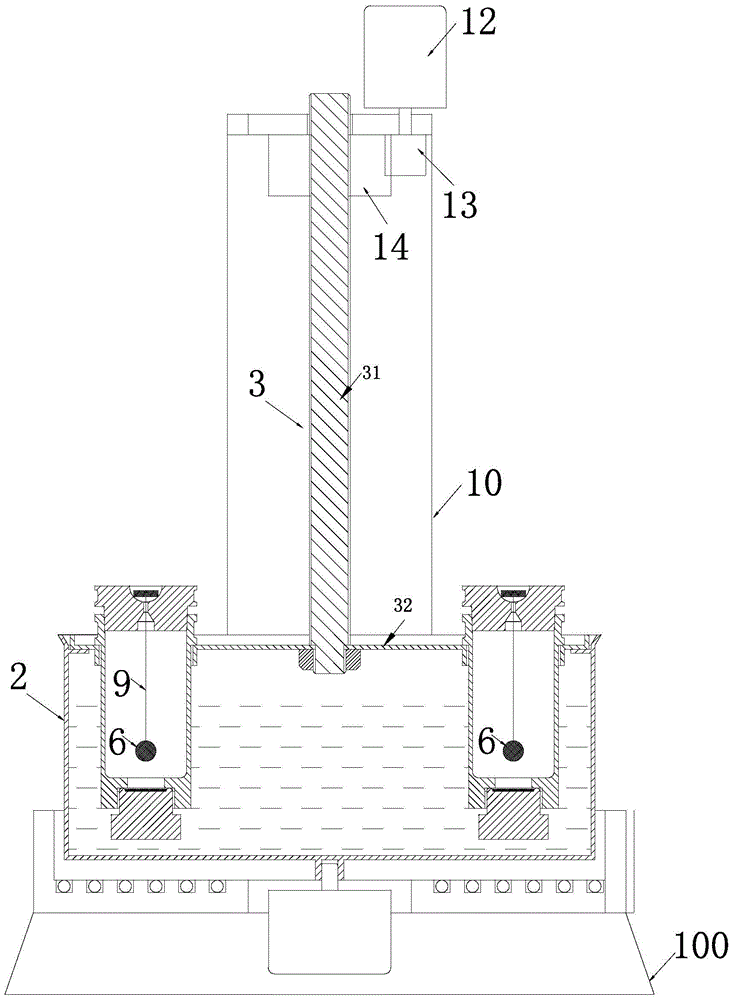

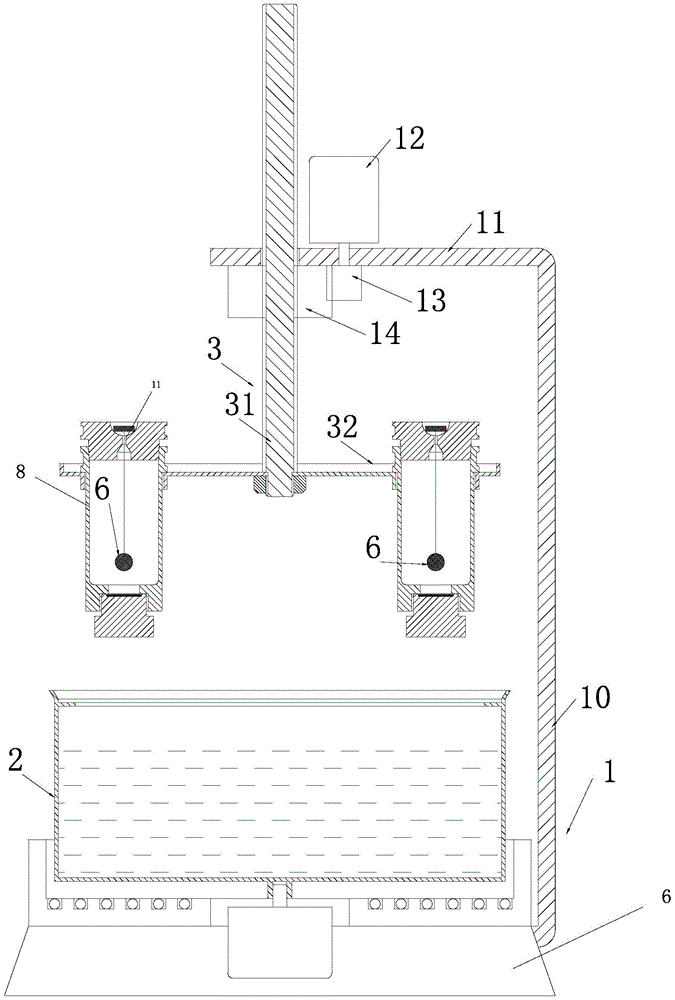

[0038] see Figure 1-7 As shown, this embodiment provides an ultrasonic multi-channel self-reaction chemical coating instrument, which mainly includes: a bracket 1 , a water tank 2 , a cup holder 3 and a plurality of sample cups 4 that can be placed on the cup holder 3 .

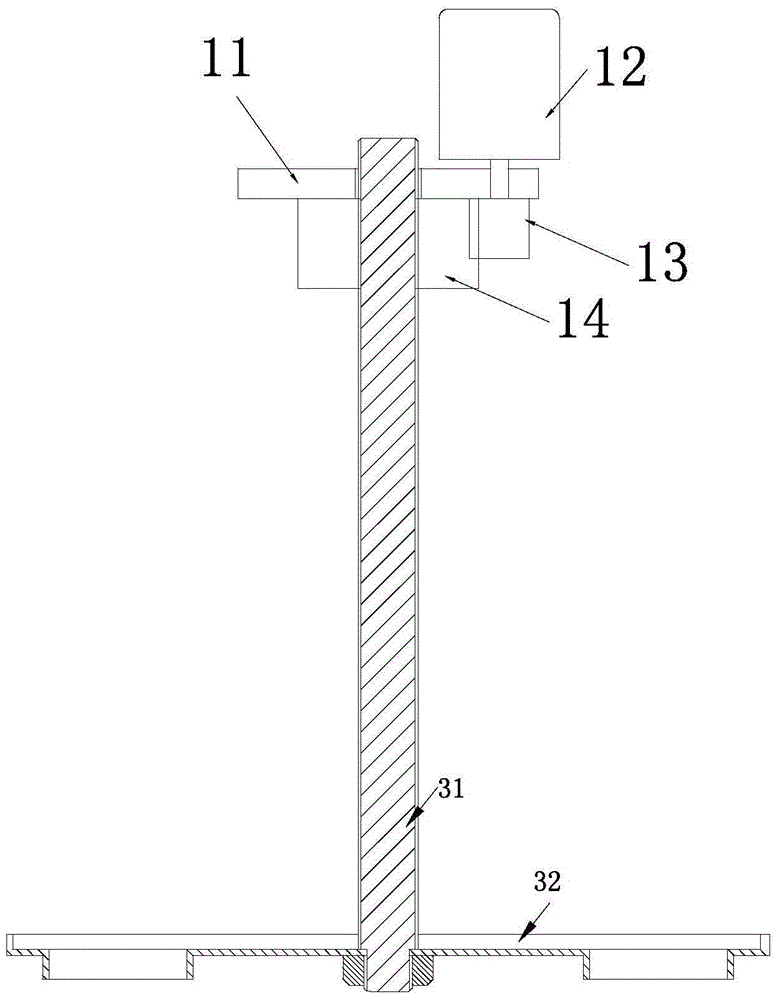

[0039] Wherein the bracket 1 includes a column 10 and a cross arm 11 arranged on the top of the column 10, the water tank 2 is positioned at the bottom of the column 10 and below the cross arm 11, the cup holder 3 includes a longitudinal screw 31 and a turntable 32, and the longitudinal screw 31 is installed on the bracket. On the cross arm 11 of the frame 1, the turntable 32 is connected to the bottom of the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com