Adhesive for indoor plywood

A technology for adhesives and plywood, applied in adhesives, monocarboxylic acid ester copolymer adhesives, aldehyde/ketone condensation polymer adhesives, etc., can solve the problem of reducing the molar ratio of formaldehyde to urea, unsatisfactory bonding water resistance, Solve problems such as high formaldehyde content, and achieve the effects of good viscosity performance, improved physical and mechanical properties, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

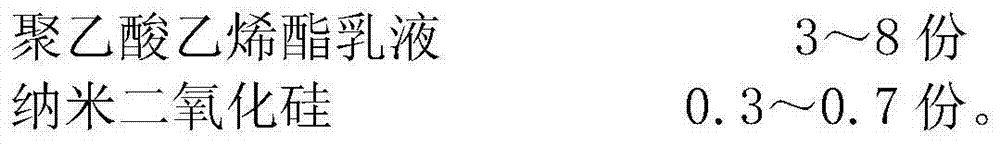

[0024] Weigh the following raw materials according to the proportion:

[0025]

[0026] The preparation method of described indoor plywood adhesive is as follows:

[0027] Blend the urea-formaldehyde resin with nano-silica, stir mechanically for 10 minutes, then add china clay and silica, continue mechanically stirring for 10 minutes, then add polyvinyl alcohol, stir mechanically for 15 minutes, then add polyvinyl acetate emulsion, stir mechanically for 8 minutes, Calcium sulfoaluminate was added, mechanically stirred for 15 minutes, then silicone rubber, octylphenol polyoxyethylene ether, polyaspartic acid, propylene glycol and sodium stearate were added in sequence, and ultrasonic wave was stirred intermittently for 100 minutes with a frequency of 90KHz and a temperature of 80°C, the adhesive for indoor plywood can be obtained.

Embodiment 2

[0029] Weigh the following raw materials according to the proportion:

[0030]

[0031] The preparation method of described indoor plywood adhesive is as follows:

[0032] Blend urea-formaldehyde resin with nano silicon dioxide, stir mechanically for 13 minutes, then add activated clay and silica, continue mechanical stirring for 9 minutes, then add polyvinyl alcohol, stir mechanically for 16 minutes, then add polyvinyl acetate emulsion, and stir mechanically for 7 minutes , and calcium sulfoaluminate was added, mechanically stirred for 18 minutes, and then silicone rubber, octylphenol polyoxyethylene ether, polyaspartic acid, propylene glycol and sodium stearate were added in sequence, ultrasonic intermittent stirring was carried out for 85 minutes, the frequency was 95KHz, and the temperature at 75°C, the adhesive for indoor plywood is obtained.

Embodiment 3

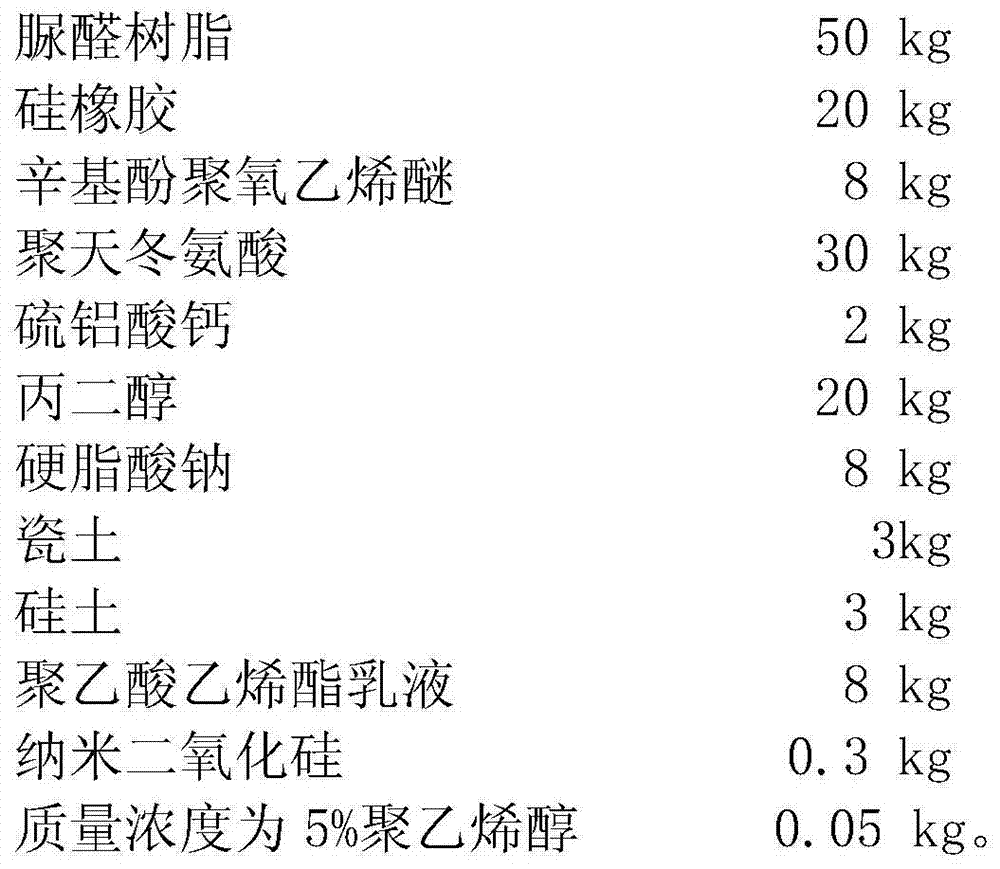

[0034] Weigh the following raw materials according to the proportion:

[0035]

[0036] The preparation method of described indoor plywood adhesive is as follows:

[0037] Blend the urea-formaldehyde resin with nano-silica, stir mechanically for 15 minutes, then add china clay and silica, continue mechanical stirring for 8 minutes, then add polyvinyl alcohol, stir mechanically for 18 minutes, then add polyvinyl acetate emulsion, stir mechanically for 5 minutes, Calcium sulfoaluminate was added, mechanically stirred for 20 minutes, then silicone rubber, octylphenol polyoxyethylene ether, polyaspartic acid, propylene glycol and sodium stearate were added in sequence, and ultrasonic waves were stirred intermittently for 75 minutes at a frequency of 105 KHz and a temperature of 70°C, the adhesive for indoor plywood can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com