Well frame, elevator with well frame and well frame mounting method

A frame and hoistway technology, used in elevators with hoistway frame and hoistway frame installation, hoistway frame field, can solve the problems of difficult handling and installation, long site installation time, lengthened construction period, etc., to shorten the installation time and solve lost and missing, avoid brittle and cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the drawings and embodiments. However, the use and purpose of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any limitation to the actual protection scope of the present invention, let alone limit the protection scope of the present invention.

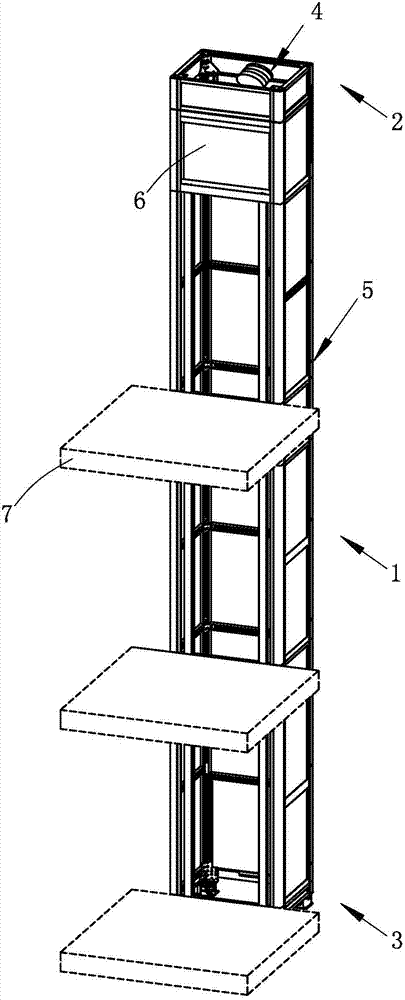

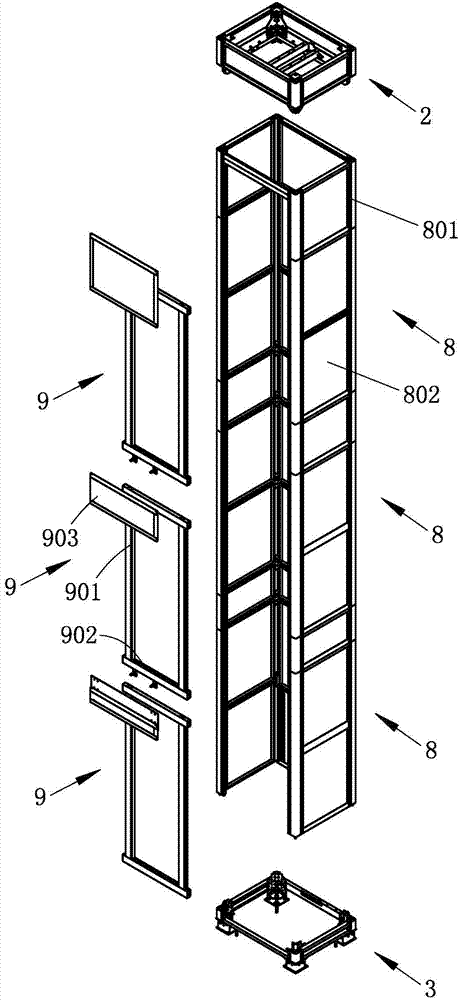

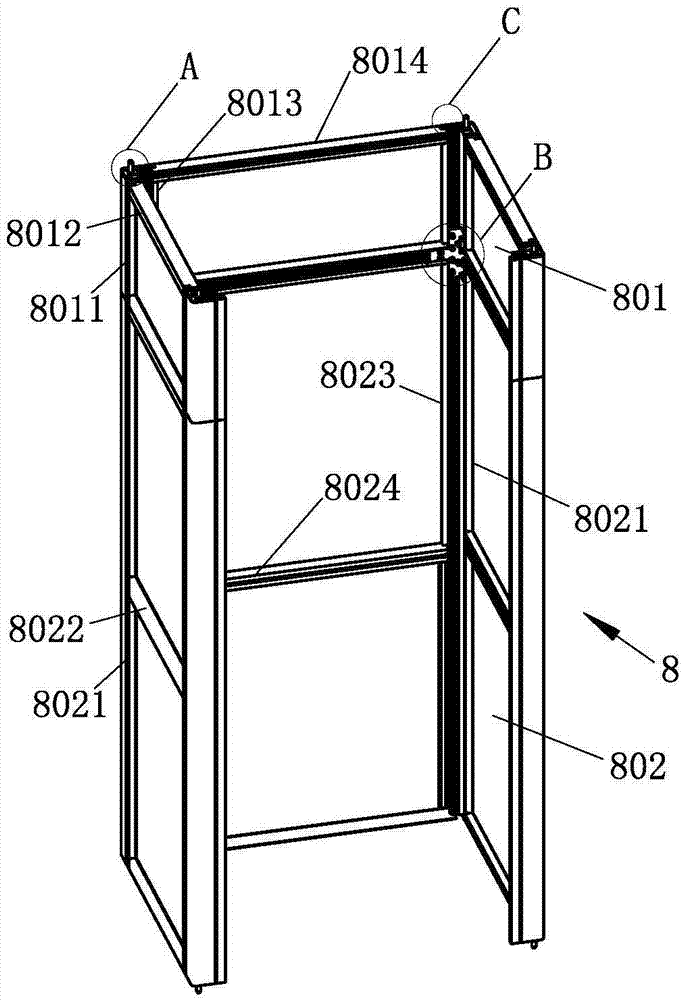

[0069] Such as figure 1 with figure 2 As shown together, the hoistway frame provided by the present invention includes a frame bottom part 3 fixedly installed on the foundation of the hoistway pit, and a frame middle part 1 fixedly installed on the frame bottom part 3 And the frame top part 2 fixedly installed between the middle part of the frame and the top of the floor. The middle part 1 of the frame is provided with a vertical opening. One of the characteristics of the middle part 1 of the frame is that it is very long. It will take a lot of time to install and adjust. In order to solve this problem, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com