Minhe main bolt hole automatic grinding machine

A main bolt hole, automatic technology, used in grinding machine tools, grinding devices, metal processing equipment and other directions, can solve the problems of unsatisfactory grinding effect, low efficiency, high labor intensity, etc., to achieve mechanized operation, convenient maintenance and storage, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

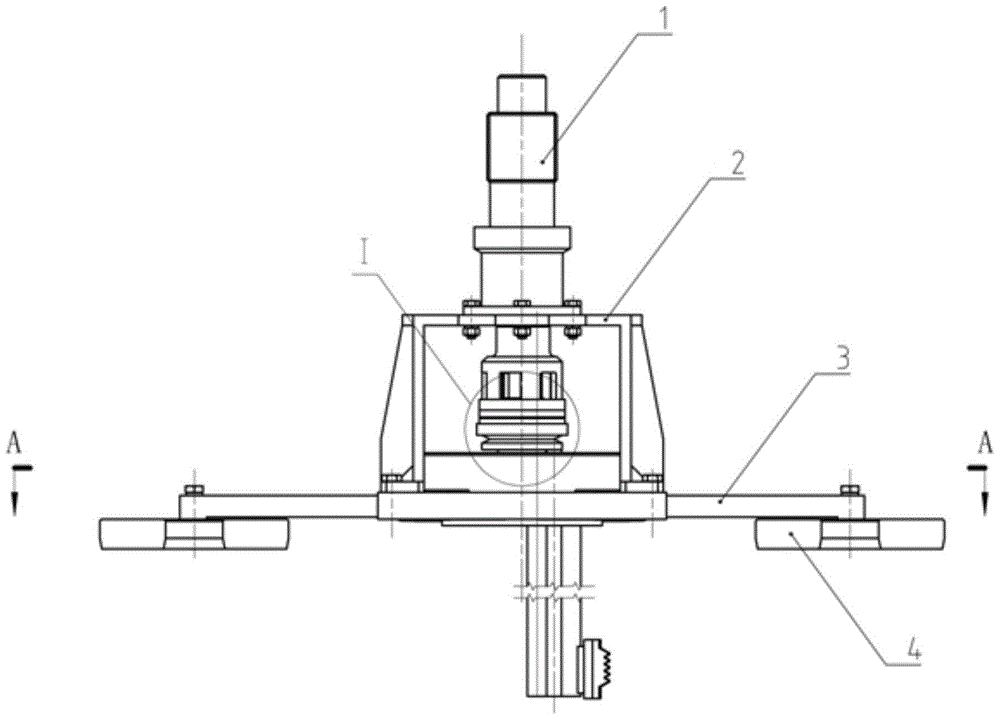

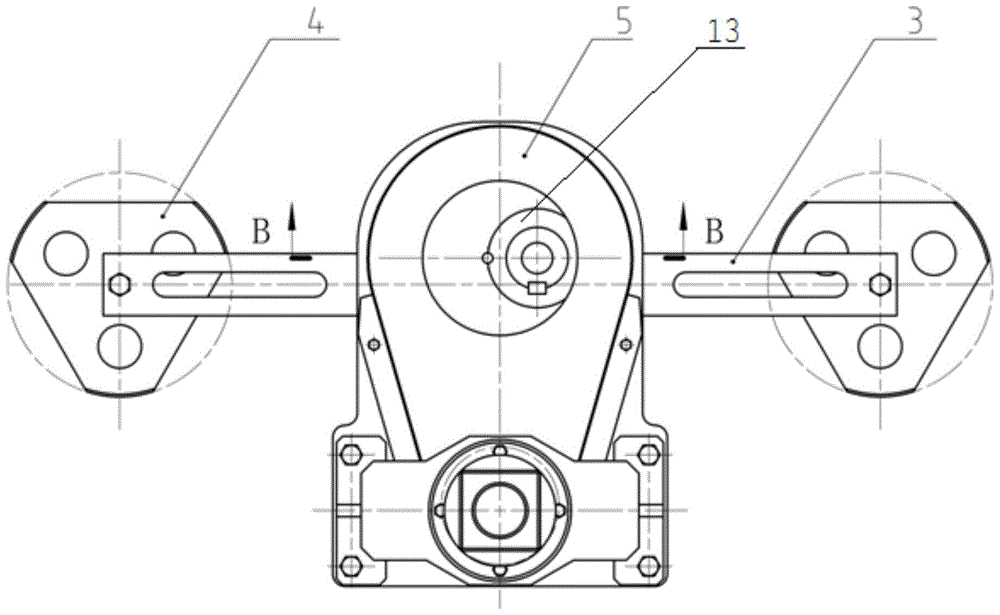

[0024] Such as Figure 1-Figure 4 As shown, a special machine for automatic grinding of the main bolt hole of Minhe, including an air motor 1, a bracket 2, a load-bearing structural beam 3, a positioning block 4, a large pulley 6, a guide post 7, a grinder 8, a coupling 9, a small Pulley 11 and synchronous belt 12;

[0025] The two ends of the load-bearing structural beam 3 are respectively fixedly connected to the nuclear power pressure vessel cylinder through the positioning block 4, and the upper surface of the load-bearing structural beam 3 is fixedly connected with the bracket 2;

[0026] The air motor 1 is fixedly connected to the support 2;

[0027] The output end of the air motor 1 is connected with the coupling 9, and the coupling 9 is fixedly connected with the small pulley 11, and the small pulley 11 is connected with the large belt through the synchronous belt 12. wheel 6 connection;

[0028] The guide post 7 is eccentrically connected with the large pulley 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com