Mould for manufacturing cover ring of auto seat and method thereof

A technology for car seats and moulds, applied in the direction of manufacturing tools, forming tools, feeding devices, etc., can solve the problems of different structures and methods, complex structural design, high scrap rate, etc., to achieve quality improvement, reasonable structural design, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] see Figure 1 ~ Figure 2 , which is the structure and shape of the linkage piece 11 made by the present invention, the linkage piece 11 includes a triangular hole 111, a long hole 112 and a concave 114 connected together, the triangular hole 111 is located at the center of the body 113, and the long hole 112 There are three and evenly distributed on the body 113, and there are three evenly distributed indentations 114 on the edge of the body 113, and the elongated hole 112 is located between the triangular hole 111 and the indentation 114, and the indentation 114 and the elongated hole 112 Dislocation distribution in the circumferential direction of the main body 113 .

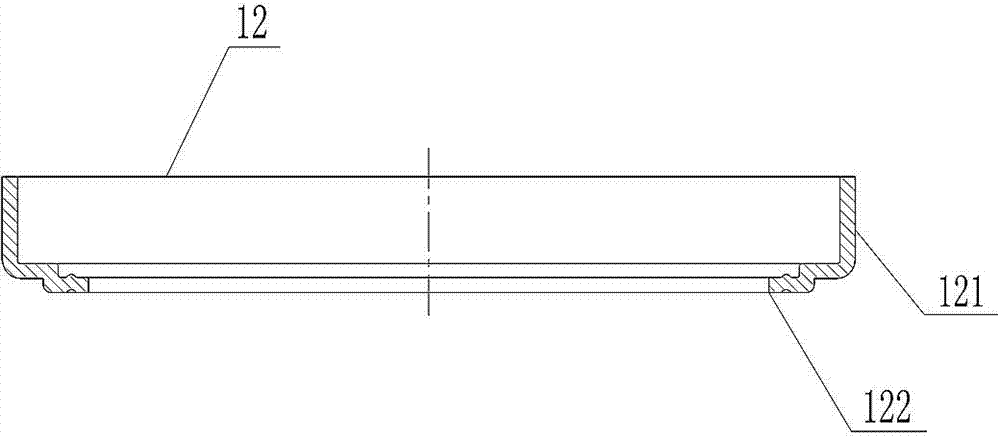

[0049] see Figure 3 ~ Figure 4 , which is the structure and shape of the envelope 12 made by the present invention, the envelope 12 includes an outer ring 121, an inner ring 122, a convex 123 and an inner hole 124 connected together, and the convex 123 is located on the inner ring 122 .

[0050] Abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com