Damping rotary seal multi-rotary-hammer crusher

A hammer crusher and rotary sealing technology, applied in the field of mineral crushing, can solve the problems of unfavorable environmental protection, low efficiency of crushing ore, and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

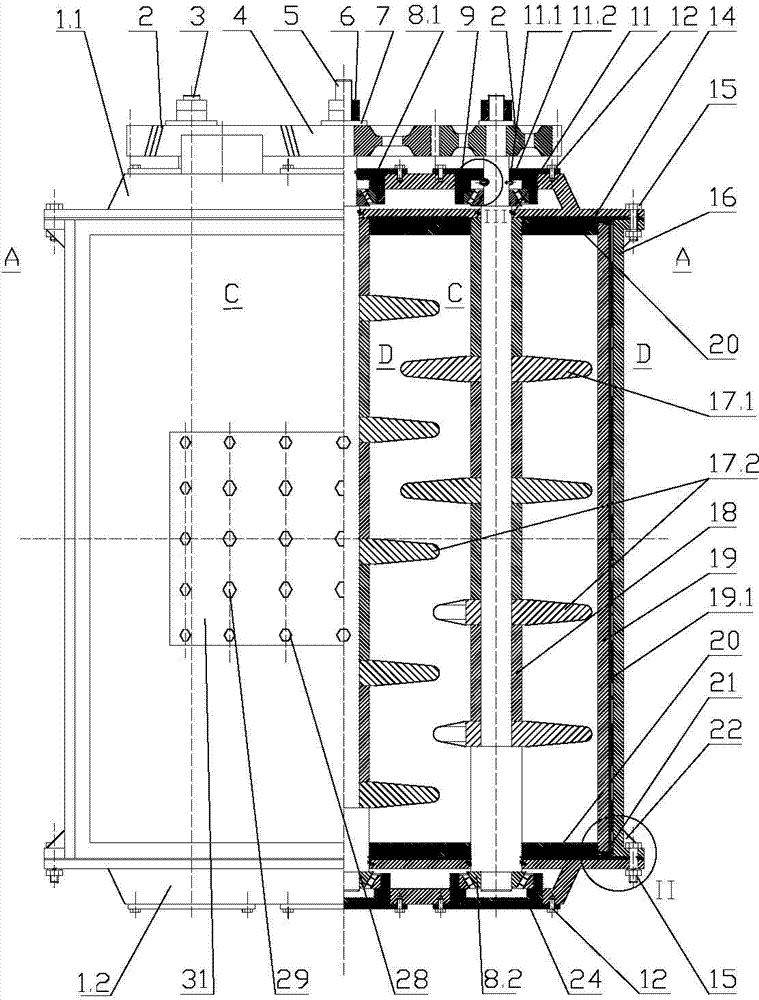

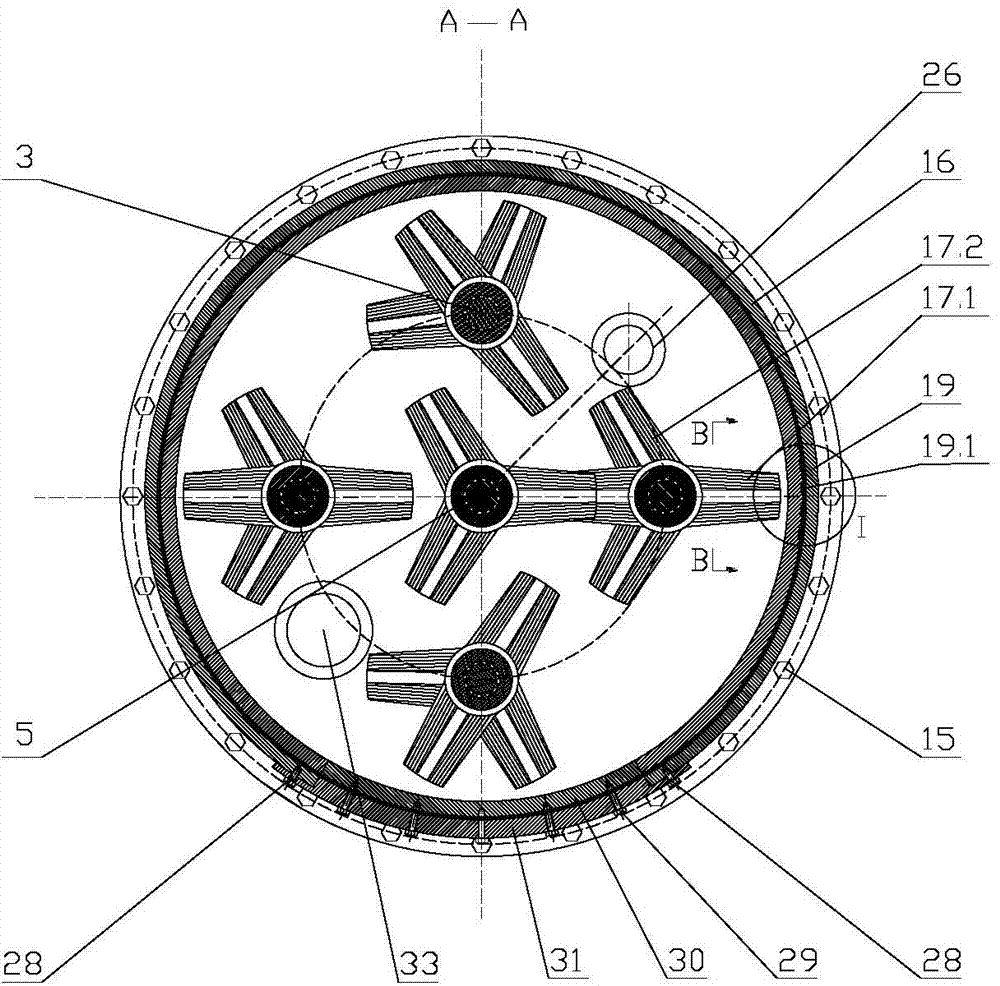

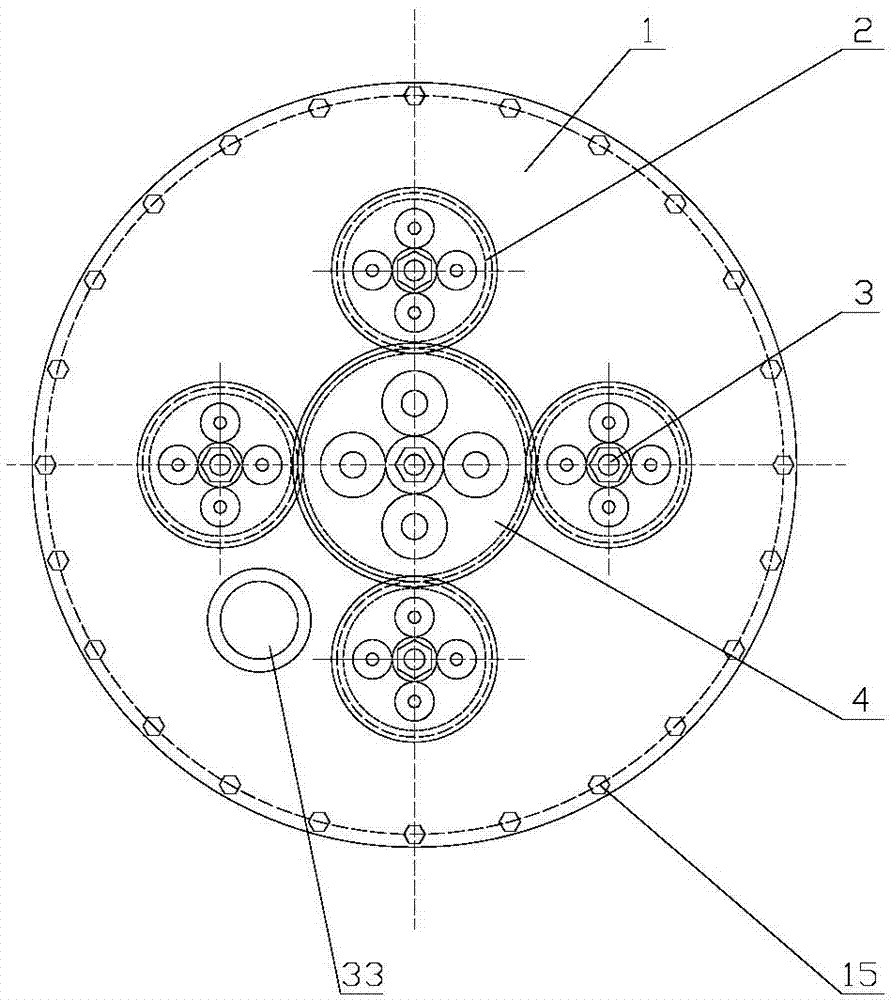

[0079] 1. Damping, shock-absorbing, rotary and sealed multi-turn hammer crusher, characterized in that: damping, shock-absorbing, rotary and sealed multi-turn hammer crusher, including: upper bearing housing 1.1, lower bearing housing 1.2, driven gear 2, driven transmission Shaft 3, driving gear 4, driving transmission shaft 5, gear compression nut 6, gear compression cover 7, upper tapered roller bearing 8.1, lower tapered roller bearing 8.2, bearing seat through cover 9, sealing packing 11, rotary seal Ring 11.1, rotary sealing ring set screw 11.2, bearing cover mounting nut 12, cylinder body gasket 14, box body mounting bolt 15, crusher cylinder body 16, flat paddle type sand hammer 17.1, three-leaf type sand hammer 17.2. Axial positioning sleeve for sand hammer 18, wear-resistant liner 19, wear-resistant liner shock absorber 19.1, convex wear-resistant end plate 20, wear-resistant liner end plate shock-absorbing gasket 21, rib plate 22 , Bearing block cover 24, discharge p...

Embodiment 2

[0130] 1. Damping, shock-absorbing, rotary and sealed multi-turn hammer crusher, characterized in that: damping, shock-absorbing, rotary and sealed multi-turn hammer crusher, including: upper bearing housing 1.1, lower bearing housing 1.2, driven gear 2, driven transmission Shaft 3, driving gear 4, driving transmission shaft 5, gear compression nut 6, gear compression cover 7, upper tapered roller bearing 8.1, lower tapered roller bearing 8.2, bearing seat through cover 9, sealing packing 11, rotary seal Ring 11.1, rotary sealing ring set screw 11.2, bearing cover mounting nut 12, cylinder body gasket 14, box body mounting bolt 15, crusher cylinder body 16, flat paddle type sand hammer 17.1, three-leaf type sand hammer 17.2. Axial positioning sleeve for sand hammer 18, wear-resistant liner 19, wear-resistant liner shock absorber 19.1, convex wear-resistant end plate 20, wear-resistant liner end plate shock-absorbing gasket 21, rib plate 22 , Bearing block cover 24, discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com