High-voltage large-current electronic switch

An electronic switch, high current technology, applied in electronic switches, electrical components, pulse technology and other directions, can solve problems such as difficulty, cumbersome process, cumbersome and other problems, achieve the effect of reducing cumbersome and difficult, solving poor linearity, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

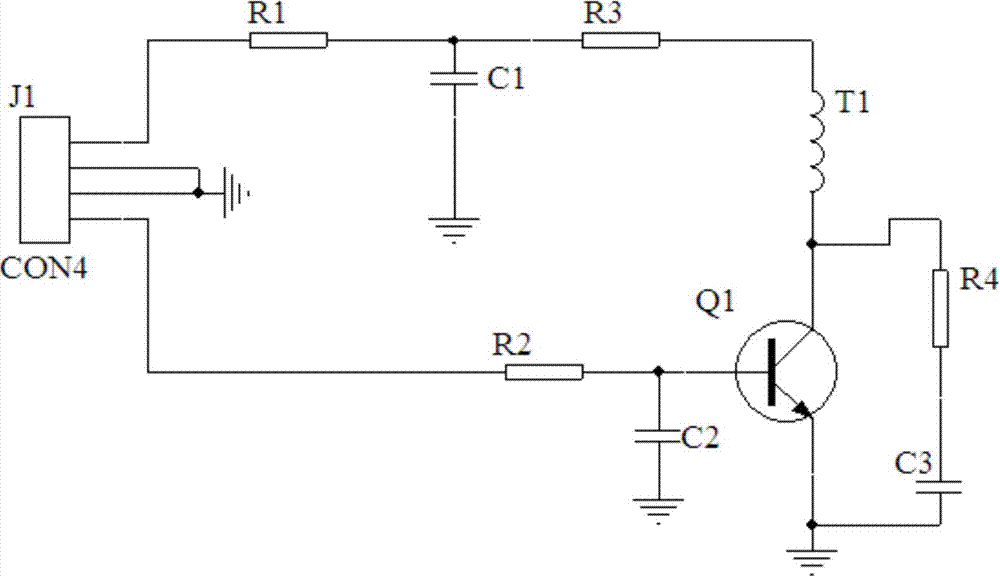

[0018] A high-voltage high-current electronic switch, including a drive circuit module, a high-voltage processing module, and a thyristor control module connected in sequence, such as figure 1 As shown, the drive circuit module includes a plug J1, a triode circuit, a coil wire T1 and a DC auxiliary energy storage circuit, the plug J1 is respectively connected to the triode circuit and the DC auxiliary energy storage circuit, and the triode circuit, the wiring The coil wire T1 and the DC auxiliary energy storage circuit are sequentially connected.

[0019] The DC auxiliary energy stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com