LED flip chip die attach method

A wafer and die-bonding technology, which is applied in the field of LED flip-chip die-bonding, can solve the problems of low LED flip-chip die-bonding yield rate, complicated process, and high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

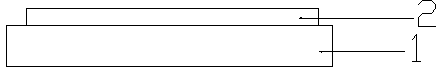

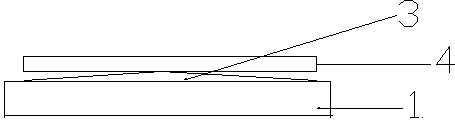

[0013] The present invention provides a method for bonding LED flip chips, as shown in FIG. 1 . Clean the ceramic bottom plate 1 with alcohol, apply the organic acid flux on the flexible grinding head of the grinding machine, and grind the grinding head on the ceramic bottom plate 1 at a high speed to form a uniform flux layer 2, and use an automatic crystal bonder to apply the solid crystal glue 3 points to the flux layer 2, put the LED flip chip 4 on the die-bonding glue 3, choose a reflow soldering machine with programming function and precise temperature control to heat the module according to the required curve, so that the die-bonding glue Solidification, flux volatilization, cooling, that is, the LED flip-chip die-bonding is realized.

[0014] The above is only a specific implementation mode in the present invention, but the scope of protection of the present invention is not limited thereto. Anyone who is familiar with the technology can easily think of changes or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com