Method for assembling backlight module, backlight module and display

A technology of backlight module and display panel, which is applied to components, optics, instruments, etc. of lighting devices, and can solve problems such as the inability to guarantee the stability of the glue, the strict requirements for the setting of the glue, and the complicated lamination process of the glue, etc. problems, to achieve the effect of simple structure, improved assembly efficiency and pass rate, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

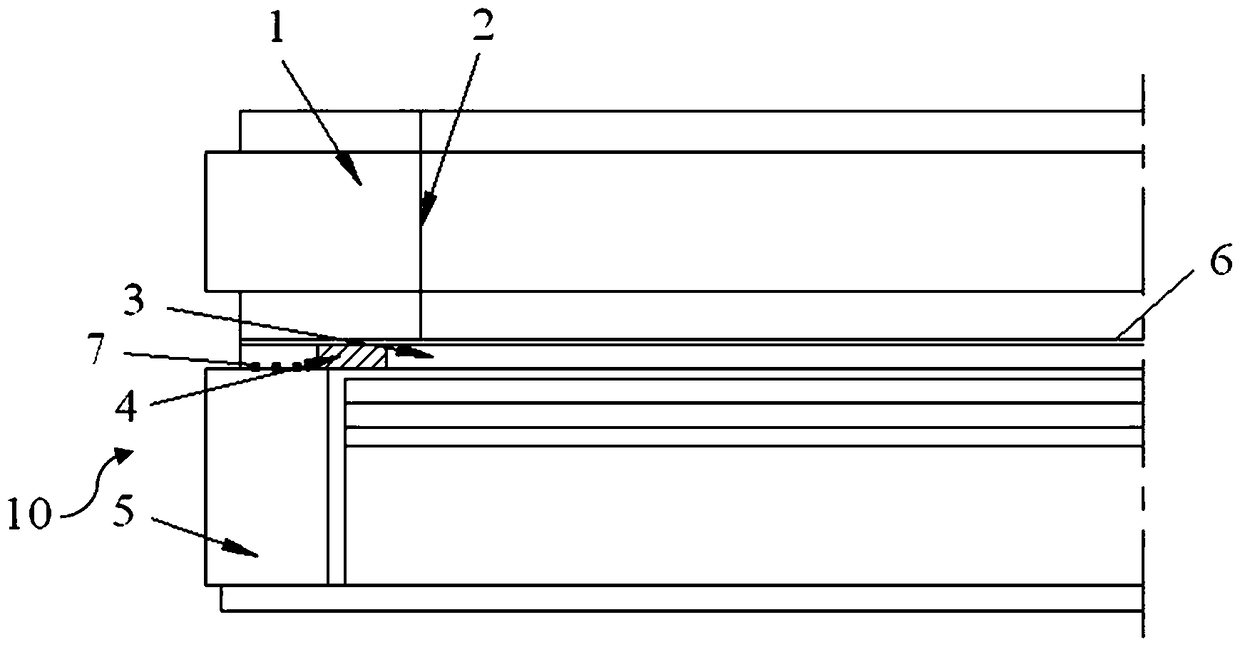

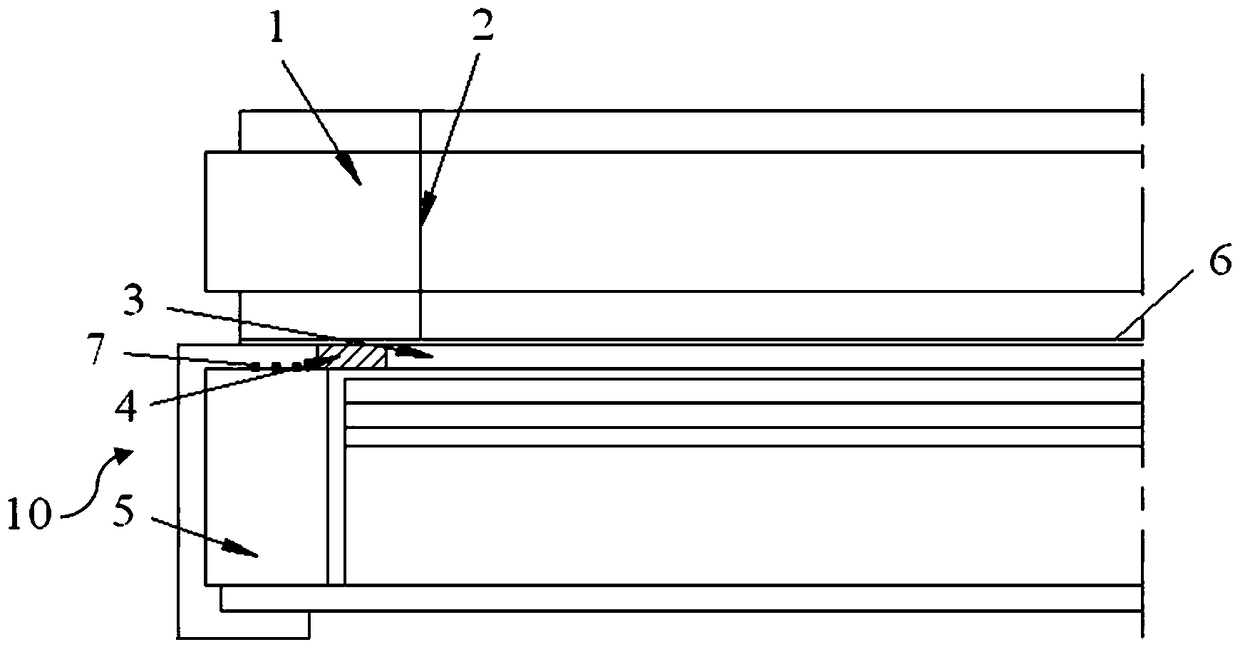

[0023] figure 1 The general structure of the assembly of the backlight module 10 and the display panel 1 of the present invention is schematically shown.

[0024] like figure 1 As shown, the backlight module 10 includes a plastic frame 5, and the plastic frame 5 of the backlight module encloses structures such as a backlight source therein. like figure 1 The display panel 1 shown in has a display area boundary 2, the left side of the display area boundary 2 is a non-display area, generally covered by the frame of the display, and the right side is a display area, from where the backlight passes through the display panel 1 to Converted into light with the expected color and brightness, so that the user can see the expected display image. The plastic frame 5 is spaced opposite to the display panel 20 .

[0025] A diffusion film 3 is provided between the display panel 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com