A Method of Raising the Main Steam Temperature of a Supercritical Once-through Boiler

A main steam temperature, once-through boiler technology, applied in steam generation, lighting and heating equipment, control systems, etc., can solve the problems of limited effect of adjusting main steam temperature, low main steam temperature, affecting blade life, etc., to achieve reduction Small cavitation damage, main steam temperature increase, and the effect of ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

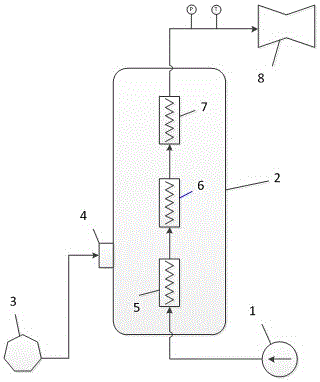

Image

Examples

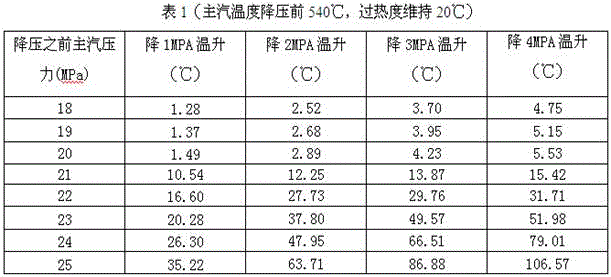

Embodiment 1

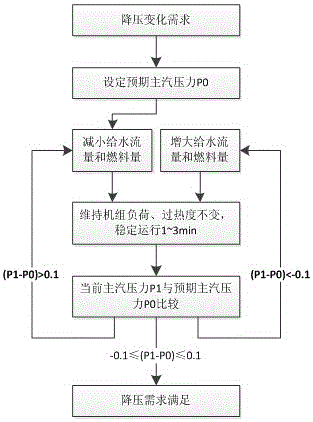

[0022] For the supercritical once-through boiler, the current main steam pressure is 25MPa, the main steam temperature is 540℃, and the superheat degree is 20℃. The pressure rate is 0.2~0.5MPa / min, and the system will synchronously control the feedwater pump 1 and coal mill 3 by judging the depressurization rate to reduce the feedwater flow and fuel volume.

[0023] When the main steam pressure drops to 23.3~23.5MPa, the automatic control system will appropriately reduce the reduction rate of the feedwater flow and fuel flow according to the current depressurization rate. If the depressurization rate is too fast, the system will increase the fuel flow and feedwater flow in advance , so that the main steam pressure slowly approaches the expected main steam pressure.

[0024] Through the adjustment in the previous step, the current main steam pressure will be closer to the expected main steam pressure. The system will judge according to the deviation between the current main ste...

Embodiment 2

[0027] For a supercritical once-through boiler, the current main steam pressure is 24MPa, the current main steam temperature is 540°C, and the superheat is 20°C. Set the expected main steam pressure to 20MPa, keep the current load and superheat Coal machine 3, after synchronously reducing the feed water flow and fuel volume, run stably for 1~3min. When the main steam pressure drops to 20.3~20.5MPa, appropriately reduce the feed water flow and fuel volume reduction rate depending on the current depressurization rate. In addition, Since the heat produced by the combustion of the unit has a certain lag after the amount of fuel is put into it, if the depressurization rate of the unit is too fast at this time, the amount of fuel and water supply should be appropriately increased.

[0028] When the main steam pressure is 0.1~0.3MPa lower than the expected main steam pressure, appropriately increase the feed water flow and fuel volume. The pressure deviation from the expected main st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com