Pectinase produced through mixed bacterium fermentation, and application thereof in tobacco sheet processing

A technology of mixed bacteria fermentation and tobacco flakes, applied in the application, tobacco, tobacco processing and other directions, can solve the problems of poor pertinence of pectin degradation, difficult to control the degradation process, and insufficient degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

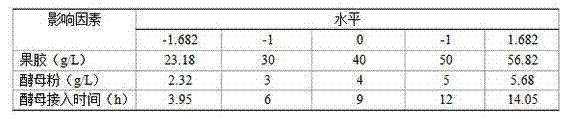

[0028] This embodiment mainly briefly introduces the process of producing pectinase by mixed bacteria fermentation and the optimization process of related medium as follows.

[0029] The pectinase produced by mixed bacteria fermentation is obtained by the following steps:

[0030] (1) Activation of strains , picking the microbial strains from the preservation medium, inoculating them into the activation medium, and culturing;

[0031] The microbial strains include: the Aspergillus niger (Aspergillus niger) with the preservation number of 3.3287 preserved by the China General Microorganism Culture Collection Center (CGMCC), and the preservation number of 1012 preserved by the China Industrial Microbiology Culture Collection Center (CICC). Saccharomyces cerevisiae; both strains were purchased from corresponding depository institutions;

[0032] The activation medium of Aspergillus niger is PDA medium (potato 300g / L, glucose 20g / L, agar 20g / L, natural pH, sterilized at 121°C),...

Embodiment 2

[0066] In this example, the crude enzyme solution prepared in Example 1 was used to degrade tobacco flakes, thereby reducing the pectin content in tobacco flakes, and further sensory evaluation and analysis were carried out. The brief introduction is as follows.

[0067] The application of the pectinase produced by mixed bacteria fermentation in Example 1 in the tobacco sheet processing process, after diluting the obtained crude enzyme solution 0 to 20 times (theoretically, the crude enzyme solution with any enzyme activity can be used to degrade pectinase) Gelase, this example only takes the crude enzyme solution with the highest enzyme activity as an example, that is, the enzyme activity is 3228.86U / mL, to discuss the degradation effect of pectinase and the improvement of tobacco quality), and carry out biological Degradation treatment. The specific process is:

[0068] The crude enzyme liquid was evenly sprayed on 10 g of tobacco flakes with a small sprayer at different ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com