A biomass pyrolysis system for carbon gas cogeneration

A biomass thermal cracking and cogeneration technology, applied in the field of biomass thermal cracking system, can solve the problems of easy leakage, incomplete equipment matching, low efficiency, etc., to ensure personal safety, complete supporting equipment, and improve heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

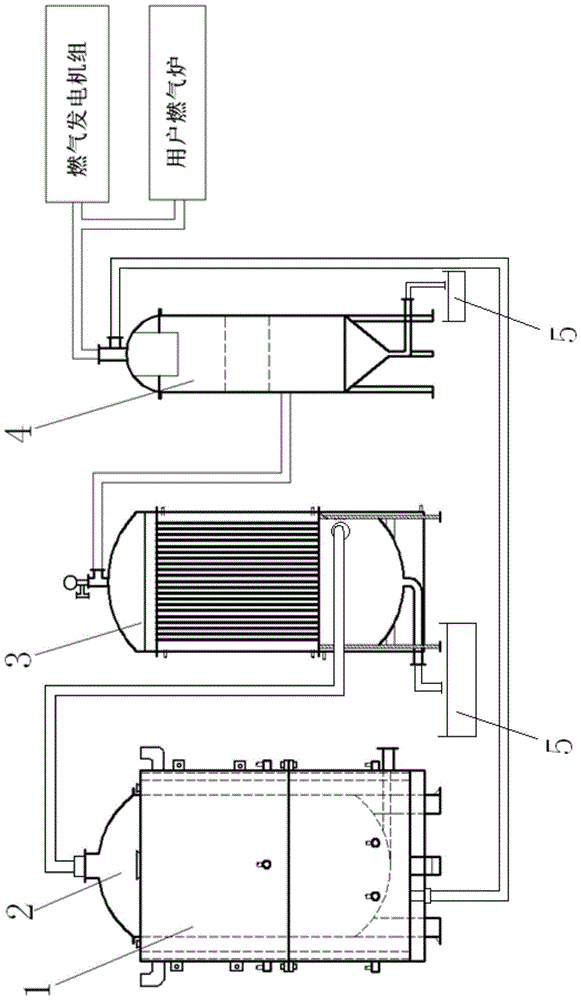

[0031] Such as figure 1 As shown, the present invention includes a heating furnace 1 , a reaction kettle 2 , a condensation tower 3 and a filtering device 4 . Wherein, the still body of reactor 2 is located in the hearth of heating furnace 1, and the gas outlet end of reactor 2 is connected to the inlet port of condensation tower 3 through pipeline, and the gas outlet end of condensation tower 3 is connected to the inlet of filter device 4 through pipeline. At the end, the filter device 4 is provided with two gas outlets, one of which is connected to a gas generator set and a user gas furnace through a pipeline, and the other gas outlet is connected to the inlet at the bottom of the heating furnace 1 through a pipeline.

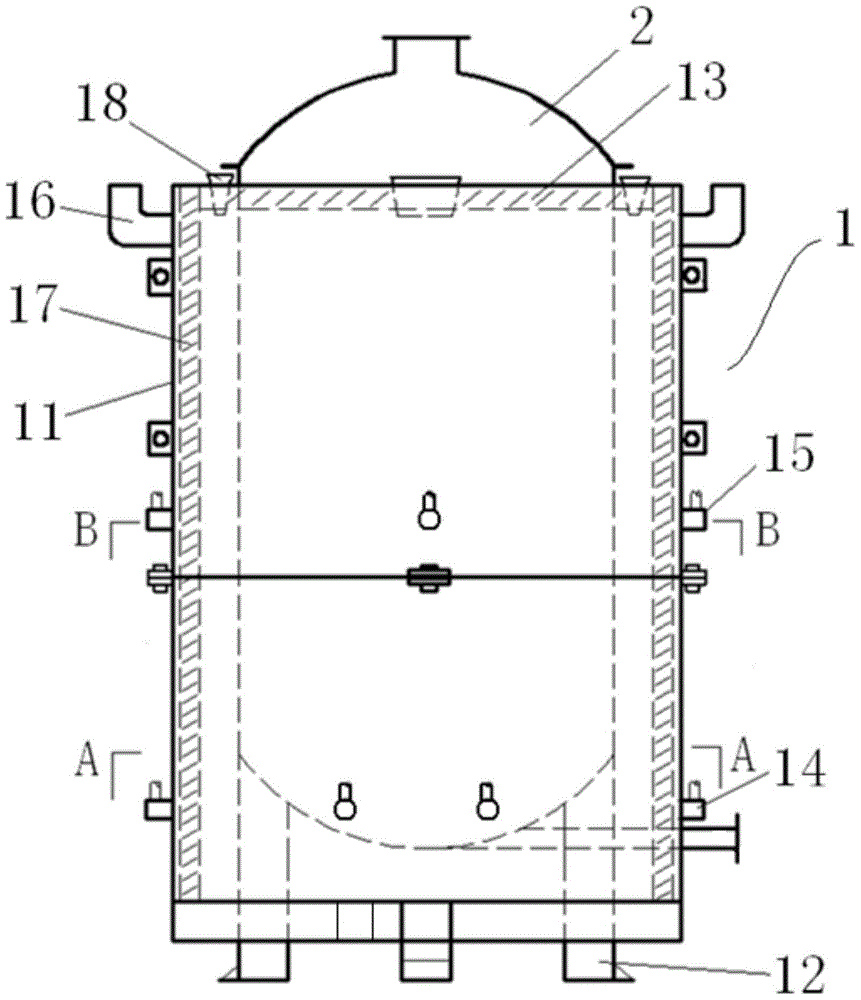

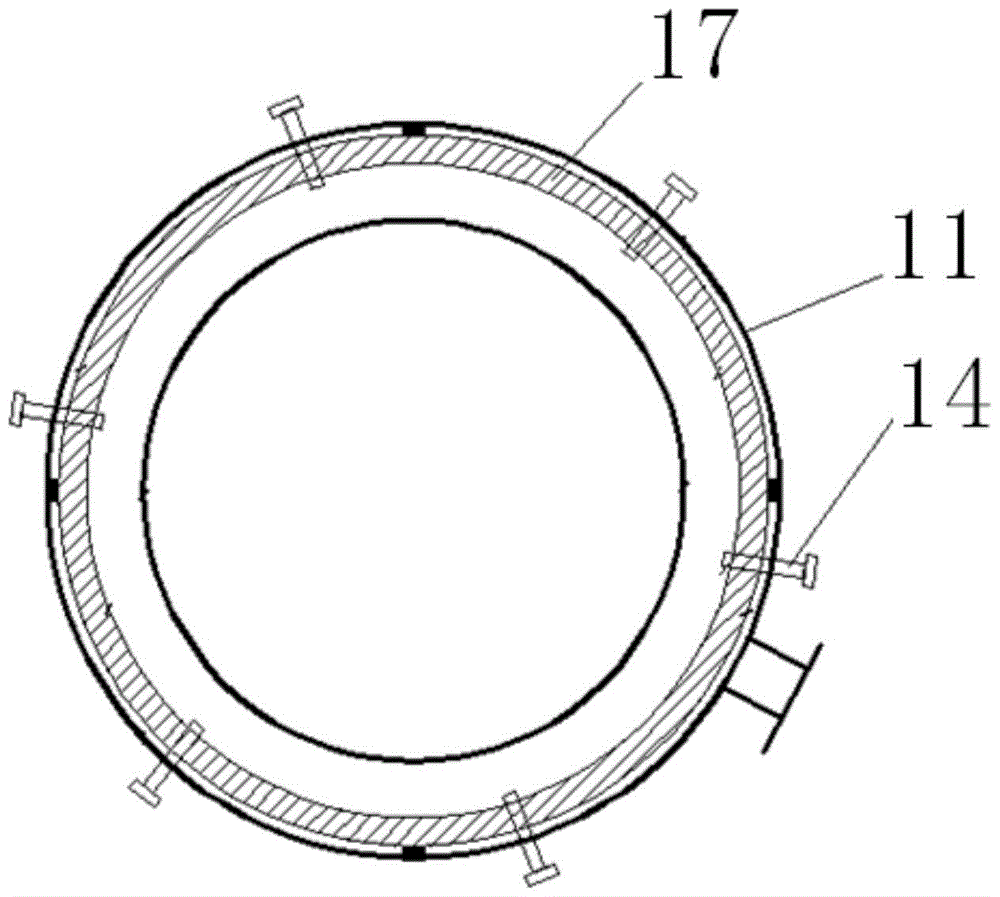

[0032] Such as Figure 2-4 As shown, the heating furnace 1 of the present invention includes a cylindrical furnace body 11 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com