Preparation process of wet-process superfine modified calcium carbonate

A preparation process and ultra-fine technology, applied in chemical instruments and methods, inorganic compound addition, inorganic pigment treatment, etc., can solve the problems of high production cost, low production efficiency, high oil absorption value, etc., and achieve low production cost and high production efficiency , The effect of low oil absorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

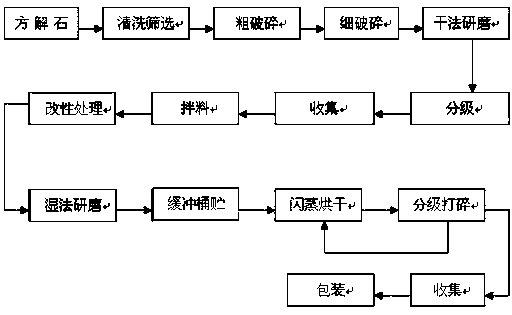

[0023] Embodiment 1, wet process ultrafine modified calcium carbonate preparation process, is characterized in that the preparation process concrete steps of wet process ultrafine modified calcium carbonate are as follows:

[0024] (1) Clean and screen the calcite ore;

[0025] (2) Coarsely crushing the cleaned and screened calcite;

[0026] (3) Carry out fine crushing on the coarsely crushed calcite;

[0027] (4) Use a mill to dry-grind the finely crushed calcite;

[0028] (5) Classify the calcite powder obtained after dry grinding, and collect 600-mesh fine powder;

[0029] (6) Mix the collected 600-mesh calcite powder with water, wherein the solid content is 70%;

[0030] (7) Add solid content of 6‰ modifier sodium stearate to the slurry obtained in step (6) for modification treatment, then enter wet grinding, add grinding media zirconia microbeads and dispersant sodium polyacrylate to the grinding , the volume ratio of grinding medium to slurry is 1:1.5, and the speed ...

Embodiment 2

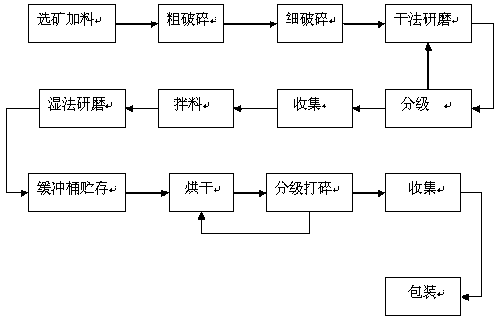

[0037] Embodiment 2, wet process ultrafine modified calcium carbonate preparation process, is characterized in that the preparation process concrete steps of wet process ultrafine modified calcium carbonate are as follows:

[0038] (1) Clean and screen the calcite ore;

[0039] (2) Coarsely crushing the cleaned and screened calcite;

[0040] (3) Carry out fine crushing on the coarsely crushed calcite;

[0041] (4) Use a mill to dry-grind the finely crushed calcite;

[0042] (5) Classify the calcite powder obtained after dry grinding, and collect 600-mesh fine powder;

[0043] (6) Mix the collected 600-mesh calcite powder with water, wherein the solid content is 80%;

[0044](7) Add the slurry obtained in step (6) to the modifier sodium stearate with a solid content of 9‰ for modification treatment, and then enter the wet grinding process. During the grinding, add grinding media zirconia microbeads and dispersant sodium polyacrylate, The volume ratio of grinding media to sl...

Embodiment 3

[0051] Embodiment 3, wet process ultrafine modified calcium carbonate preparation process, is characterized in that the preparation process concrete steps of wet process ultrafine modified calcium carbonate are as follows:

[0052] (1) Clean and screen the calcite ore;

[0053] (2) Coarsely crushing the cleaned and screened calcite;

[0054] (3) Carry out fine crushing on the coarsely crushed calcite;

[0055] (4) Use a mill to dry-grind the finely crushed calcite;

[0056] (5) Classify the calcite powder obtained after dry grinding, and collect 600-mesh fine powder;

[0057] (6) Mix the collected 600 mesh calcite powder with water, wherein the solid content is 75%;

[0058] (7) Add a solid content of 12‰ modifier sodium stearate to the slurry obtained in step (6) for modification treatment, and then enter wet grinding, and add grinding media zirconia microbeads and dispersant sodium polyacrylate to the grinding , the volume ratio of the grinding medium to the slurry is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com