Polyisoprene gasket synthesized by medicinal film

A technology of polyisoprene and film coating, which is applied in the field of synthetic polyisoprene gaskets for pharmaceutical film coating, can solve problems such as poor adhesion with film materials, and achieves overcoming poor adhesion, reducing resistance, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

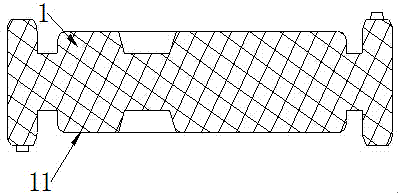

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below through specific examples.

[0021] A medical film-coated synthetic polyisoprene gasket, the formula of which is: polyisoprene rubber: 100, kaolin: 15-20, white carbon black: 5-10, zinc oxide: 5, Carbon black: 0.3, titanium dioxide: 4, vulcanizing agent: 1.2.

[0022] The thickness of the film material is 2mil ETFE film.

[0023] A medical film-coated synthetic polyisoprene gasket, the production process of which is as follows:

[0024] (1) Ingredients: Prepare various materials according to the formula and put them in the designated material hole;

[0025] (2) Rubber mixing: mix various materials evenly according to the formula;

[0026] (3) Preforming: According to the requirements, the rubber material is made into a film with a specified size and weight for vulcanization;

[0027] (4) Primary vulcanization: Put the formula rubber and membrane material on the flat vulcanizer to form the drug contact part of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com