Feed basin

A material basin and material discharge port technology, which is applied in the direction of the feeder nozzle, etc., can solve the problems of difficulty in precise control of material weight and fluctuation of material weight, so as to achieve uniform and stable material discharge, avoid material weight fluctuation, and smooth and stable flow process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

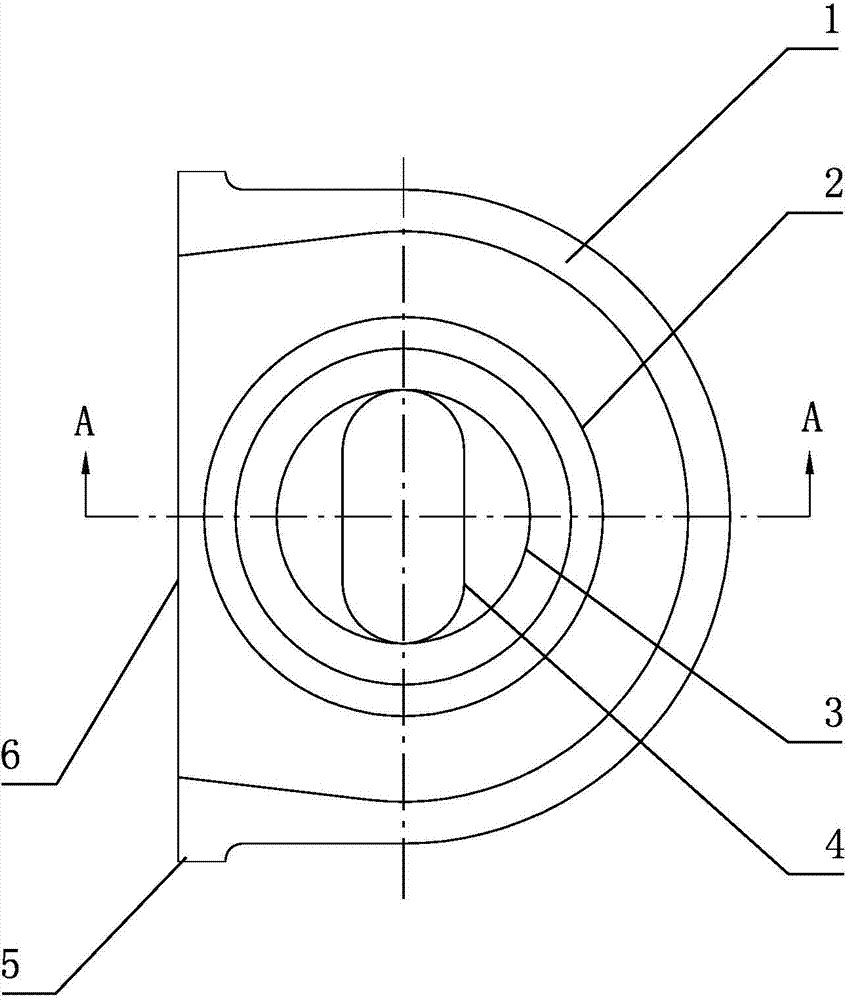

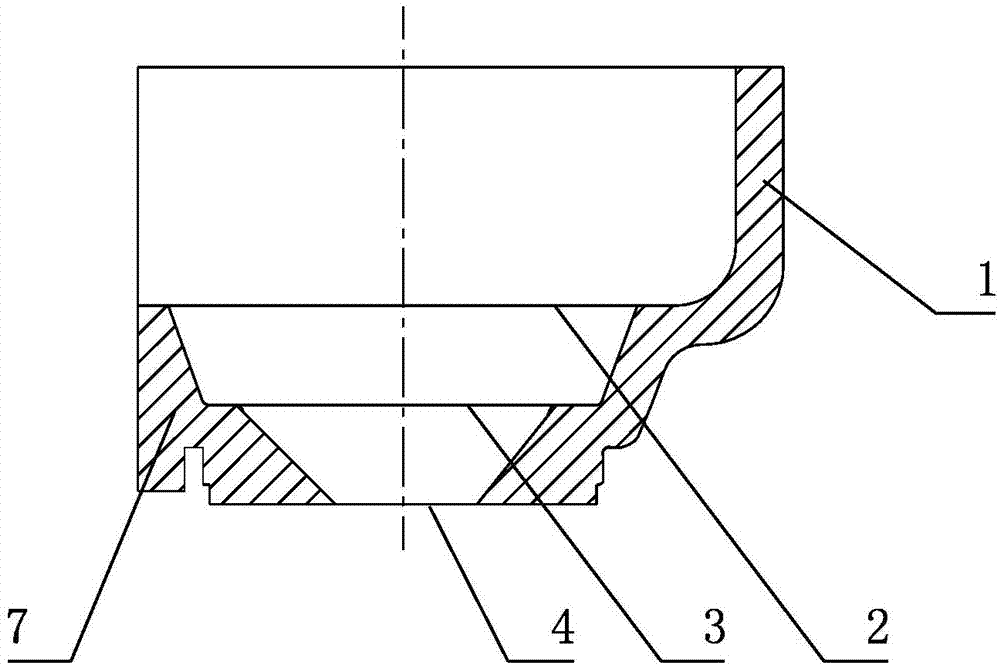

[0018] Such as figure 1 , 2 As shown, the material basin includes the material basin body 7, and the side wall 1 is arranged above the material basin body 7. The side wall 1 is composed of a semicircular arc wall and a straight wall extending outward along the two ends of the arc wall. The two straight walls The outer surface is parallel, and the inner surface is inclined inward along the extension direction, that is, there is a certain angle between the inner surface and the outer surface, and the angle is 6°~7°. If the angle is too small, it will not slow down the flow velocity. , If the inclination angle is too large, the flow at the edge of the feed liquid will cause greater resistance and form turbulent flow, which is not conducive to the stable flow of the feed liquid. Ears 5 are also provided at the outer ends of the two straight walls, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com