A high-speed pocket spring machine

A pocket spring, high-speed technology, applied in the field of spring pad production equipment, can solve the problems of increased power consumption of pocket spring machines, increased installation costs of pocket spring machines, and high noise of pocket spring machines, and achieve savings Design and installation costs, reduction in production and replacement, and reduction in the effects of circlips and stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

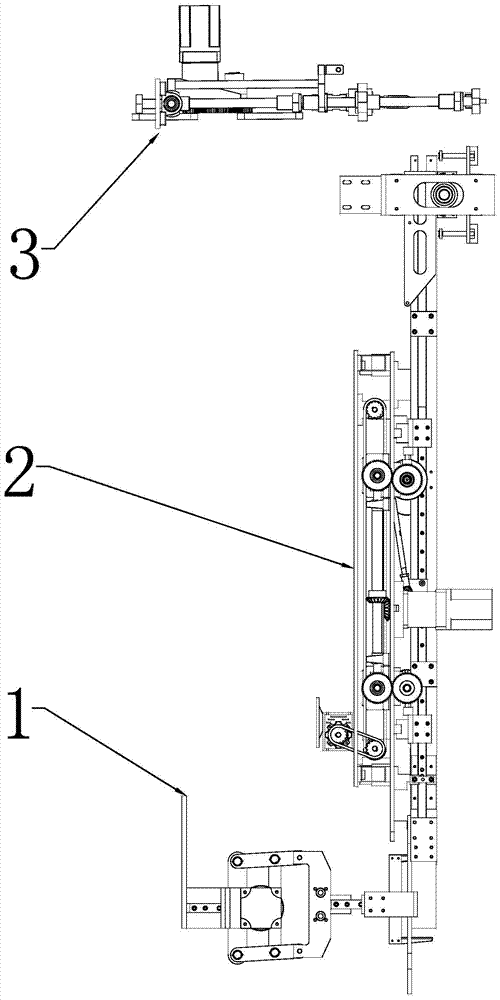

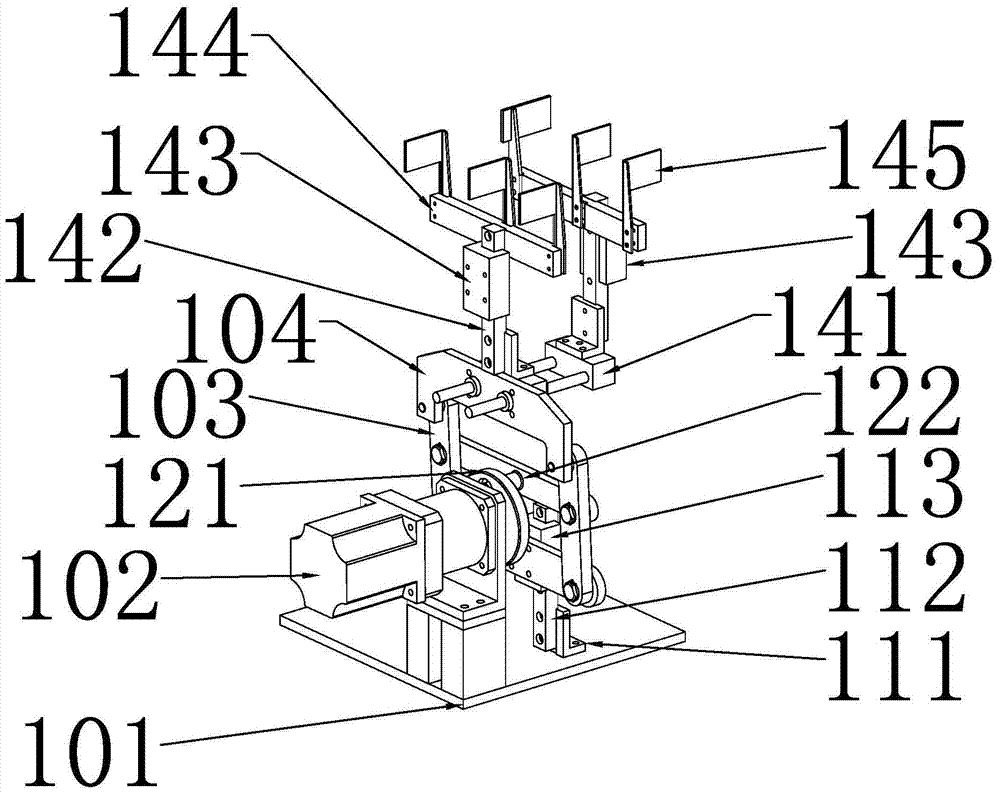

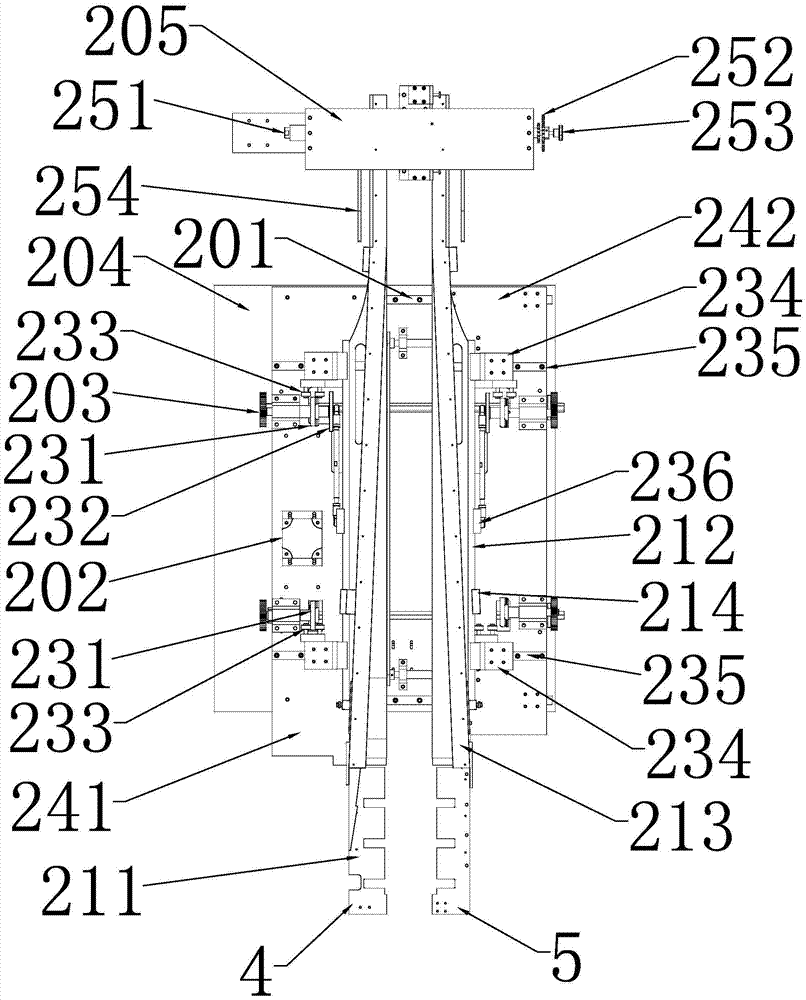

[0022] refer to Figure 1 to Figure 8 , a high-speed pocket spring machine, including a transmission mechanism 1, a transmission mechanism 2, and a vertical welding mechanism 3, the transmission mechanism 2 is provided with a left transmission arm 4 and a right transmission arm 5, and the front end of the transmission mechanism 2 is provided with The rear end of the transmission mechanism 1 is provided with a vertical welding mechanism 3, and there is a space between each other, and the transmission mechanism 1, the transmission mechanism 2, and the vertical welding mechanism 3 are arranged and fixed on the frame in sequence.

[0023] In the present invention: the transmission mechanism 2 includes a fixed platform 204, a fixed plate 241, a movable plate 242, a left transmission arm 4, a right transmission arm 5, a motor 202, a gear set 203, and a cloth welding mechanism 205. The fixed platform 204 A fixed seat and a sliding seat 201 are arranged on the fixed seat, a fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com