High-barrier double-sided heat-sealable tissue membrane and preparation method thereof

A high-barrier, double-sided technology, applied in the field of high-barrier double-sided heat-sealing tissue film and its preparation, can solve problems such as no application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

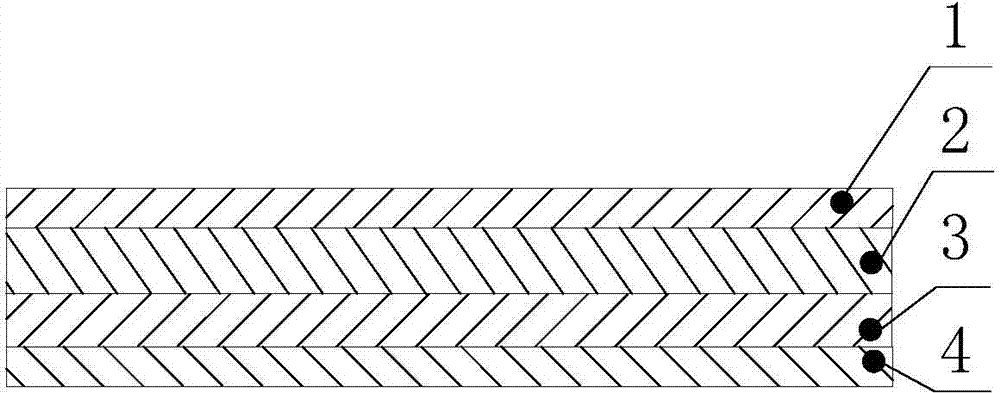

[0021] Such as figure 1 As shown, a high-barrier double-sided heat-sealed paper towel film is composed of a heat-seal layer 1, a first core layer 2, a second core layer 3, and a corona layer 4, which are sequentially arranged and cast four-layer co-extrusion; The mass percentages of the heat-sealing layer 1, the first core layer 2, the second core layer 3, and the corona layer 4 are respectively: 20%, 31%, 31%, and 18%;

[0022] The material of the heat-sealing layer is composed of binary copolymer (F800E) [binary random polypropylene copolymer], terpolymer (C5608) [terpolymer polypropylene C5608], homopolymer (addition of homopolymer different heat-sealing temperature), antistatic agent (excellent antistatic performance), smooth agent (to ensure its smooth performance, or masterbatch 503P-19), the mass percentage of each raw material is: 25% , 47.5-48%, 24-24.5%, 0.5-1%, 2-2.5%.

[0023] The homopolymer is PP homopolymer (homopolymer PP). The antistatic agent is polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com