Nail head device and box nailer for corrugated cardboard stapling

A technology of corrugated cardboard and nail head machine, which is used in paper/cardboard containers, packaging, papermaking, etc., can solve the problems of not smooth up and down displacement of cutter and die, and achieve the effect of compact structure, stable up and down displacement, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

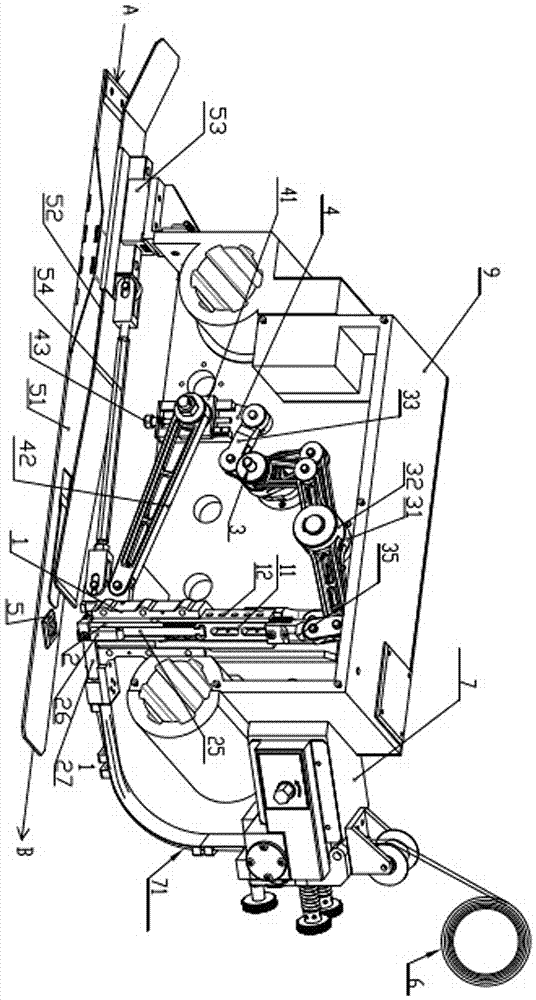

[0023] With regard to the above technical solution, a preferred embodiment will be given and detailed description in conjunction with the figure. The nail box machine of the present invention mainly includes a driving device, a nail head device and a wire feeding device, see Figure 1~Figure 6 ,among them.

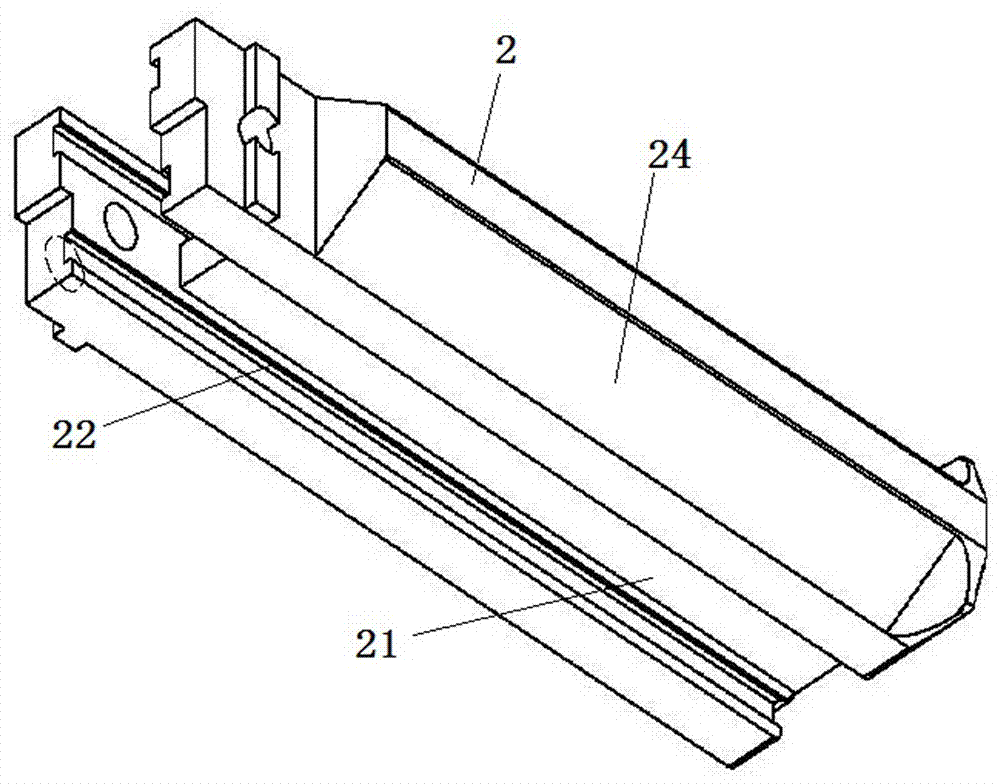

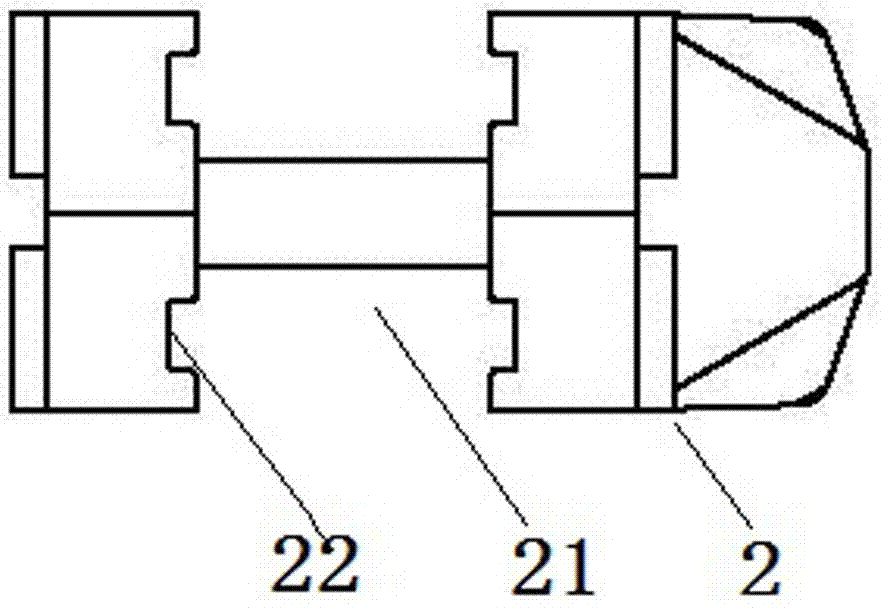

[0024] The nail head device includes a nail head frame 1, which has a hollow structure. Four vertical slide rails, front, rear, left, and right are fixedly arranged in the nail head frame 1, and the front and rear slide rails and the left and right slide rails are parallel to each other. Each slide rail is provided with a slider that can move up and down along the slide rail. The sliders on the front and rear slide rails are the middle punch slider 11, and the sliders on the left and right slide rails are the cutter sliders 12. The upper ends of the left and right sides of the cutter device 2 are respectively fixed on the lower ends of the left and right sliders. The cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com