Manufacturing process of solid wood composite door

A production process and wood composite technology, applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of falling off, falling on the board, uneven application of glue, etc., to prevent uneven application, reduce cracking, and apply evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

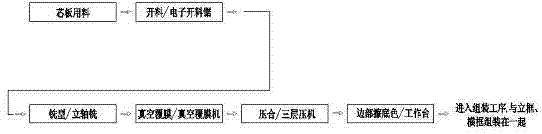

[0115] A kind of manufacturing technology of solid wood composite door, the manufacturing technology of solid wood composite door comprises the following steps:

[0116] (1) Prepare the door leaf, door casing line and door casing A and B boards at the same time

[0117] The technological process of the door leaf includes

[0118] 1) Prepare vertical frame, horizontal frame and core board at the same time,

[0119] Wherein: the manufacturing process of vertical frame comprises the following steps:

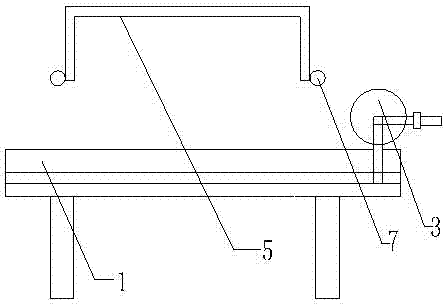

[0120] A1, vertical frame core layer: select the middle material of the vertical frame core layer 30LVL, cut the material through the multi-blade saw according to the thickness of the door leaf, and then use the sliding table saw to cut the material according to the required length for use;

[0121] A2. For the core layer of the vertical frame, select the material for the edge sealing of the vertical frame, that is, 9mm MDF and 30mmLVL composite board, and use a cold press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com