Heavy-load precise flexible adsorption mechanical arm

A manipulator and flexible technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unguaranteed precision and narrow adaptation range, and achieve the effect of high clamping precision, large adaptability and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

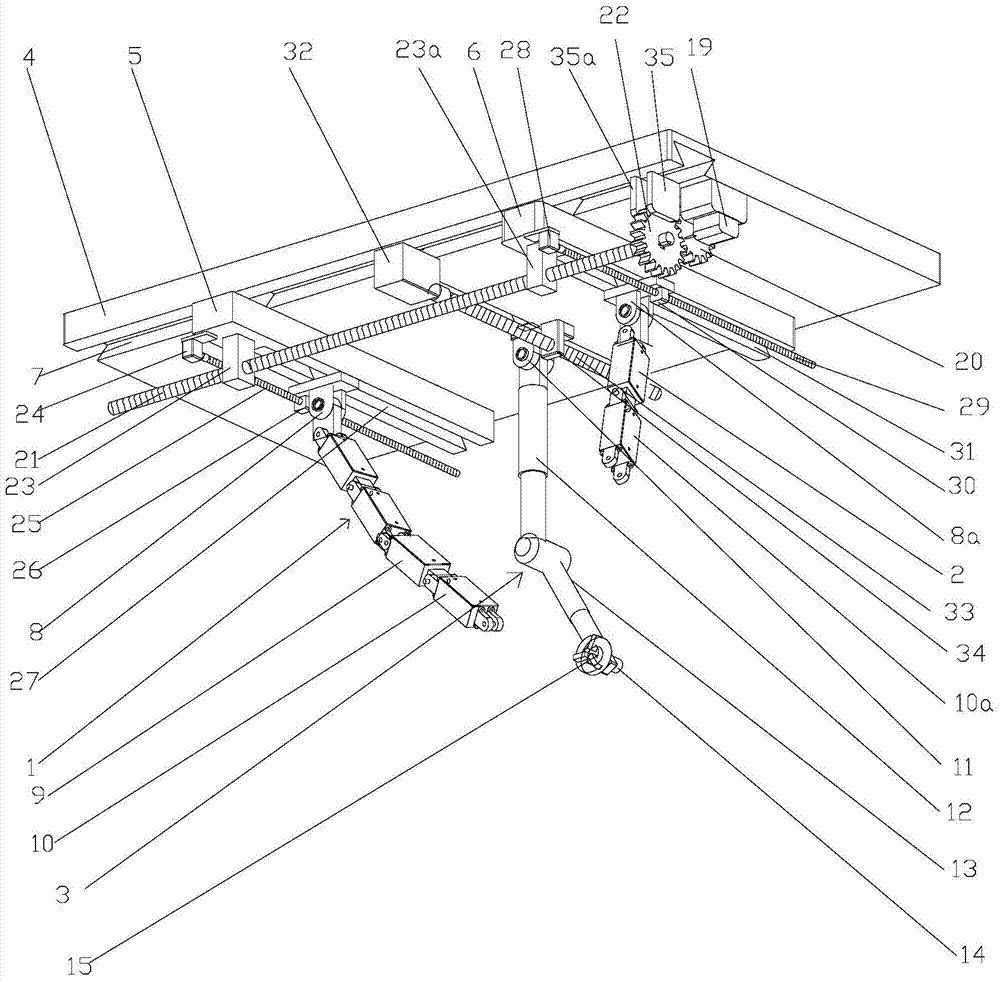

[0018] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the connection of two standard joints of the flexible electromagnetic tape of the present invention, as shown in the figure: the heavy-duty precision flexible adsorption manipulator of this embodiment includes a positioning assembly, an adsorption arm for main positioning, and a side for end faces and auxiliary positioning. To the arm 3, the adsorption arm includes the first arm 1 of the adsorption arm and the second arm 2 of the adsorption arm whose ends are detachably connected to each other, and the positioning assembly includes a positioning plate 4, a first positioning seat 5 and a second positioning seat 6. A guide groove 7 is set on the lower side of the positioning plate 4, and the first positioning seat 5 and the second positioning seat 6 are cooperating with the guide groove 7 in a manner that they can move back and forth along the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com