Turning cutter wear state monitoring system

A wear state and monitoring system technology, applied in turning equipment, manufacturing tools, accessories of toolholders, etc., can solve the problems of imperfect wear monitoring, insensitive signal characteristics, and expensive monitoring costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

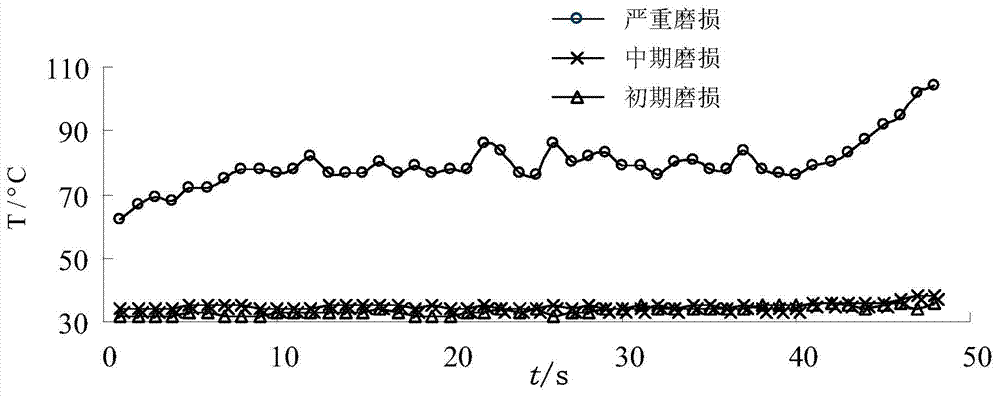

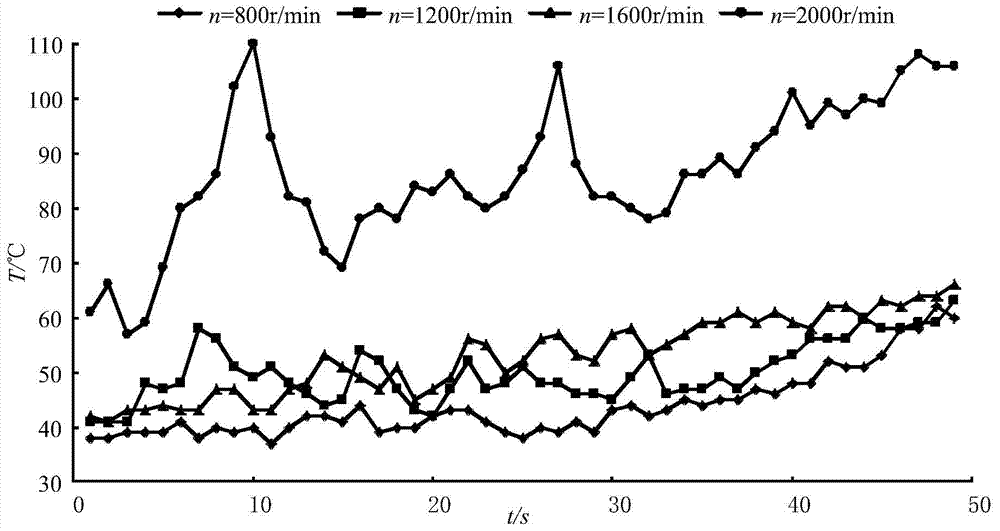

[0036] Select turning tools under three different wear states: initial wear, mid-term wear, and severe wear, and conduct turning tests for each tool according to the scheme shown in Table 1, and conduct 12 tests for each given turning depth e , the tool in each state can be turned 36 times, and the time of each test is set to 1 minute.

[0037] Table 1

[0038]

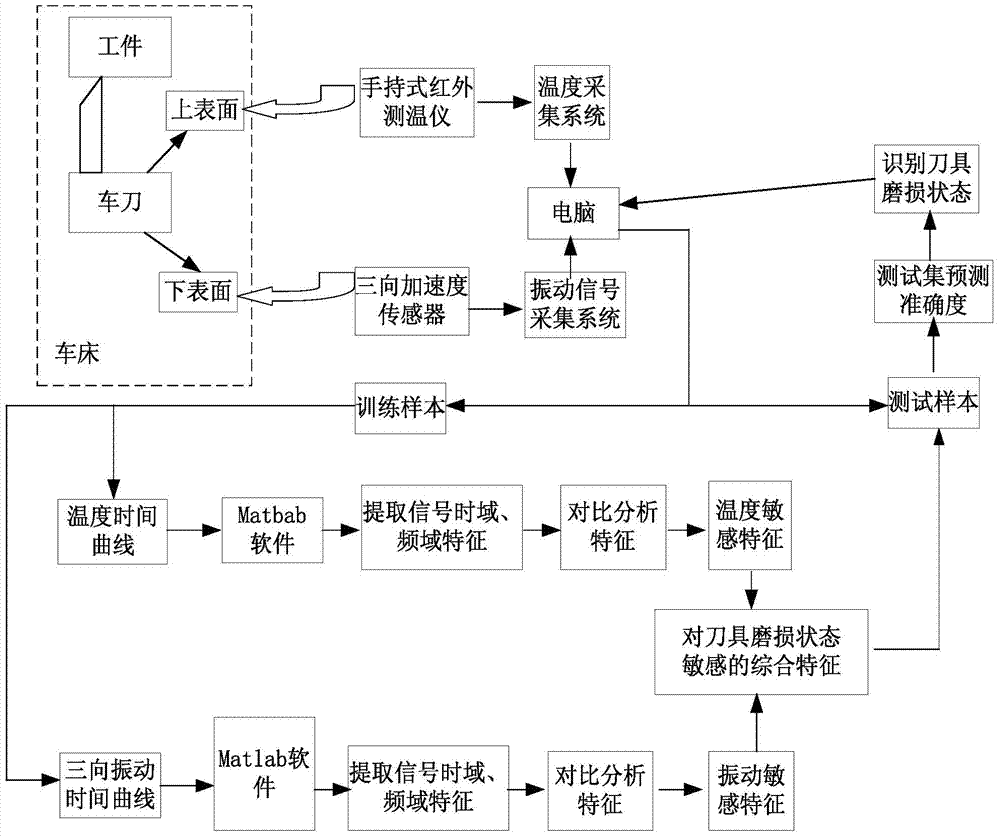

[0039] Such as figure 1 Said, build the turning tool wear state monitoring system of the present invention, comprise signal acquisition system and identification tool wear state system;

[0040] The signal acquisition system includes a temperature acquisition system and a vibration signal acquisition system. The temperature acquisition system collects the temperature at the rake face of the tool through the OS523E-2 infrared thermometer produced by the U.S. OMEGA company. The vibration signal acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com