Self-propulsion type wind and wave resistant deepwater net cage

A deep-water net cage, anti-wind and wave technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as complicated construction procedures of offshore piling operations, increased operating costs, damage to the environment, etc., to achieve protection and improvement The effect of breeding water environment, reducing the cost of offshore operations, and avoiding serious economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

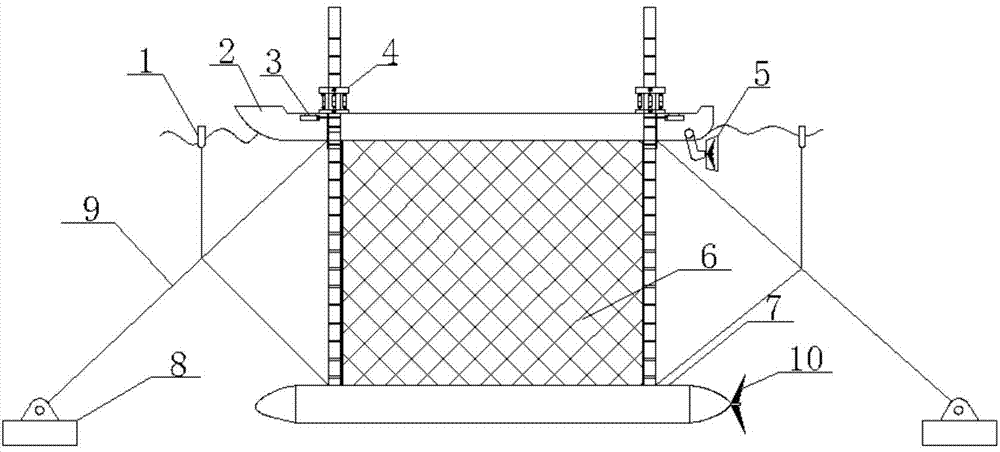

[0025] Such as figure 1 and figure 2 The self-propelled anti-wind and wave deep-water net cage shown includes a frame, a net 6, a mooring member for fixing the cage in the water, and a hydraulic propulsion device. The frame as a whole constitutes a cubic frame structure with an upper frame The upper frame and the lower frame are hollow floating structures. The upper frame constitutes the upper frame 2, and the lower frame constitutes the lower frame 7. The upper frame 2 and the lower frame 7 are arranged in parallel, and the upper frame 2 is arranged in parallel through the hydraulic plug 3 and The positioning and locking mechanism 4 is connected with the vertical frame of the frame. The upper floating body 2 can move up and down relative to the vertical frame, and is fixed at different positions on the vertical frame by the cooperation of the hydraulic bolt 3 and the positioning and locking mechanism 4. A buoy 1 is also connected to the upper floating body 2. When the deep w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com