Massage apparatus

A rotary drive, liquid tank technology, applied in bathing devices, hydraulic massage, vibration massage, etc., can solve problems such as deterioration of assembly operability, increase in the number of parts, and burning of motors, etc., to improve assembly operability, reduce the number of parts, Achieving the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

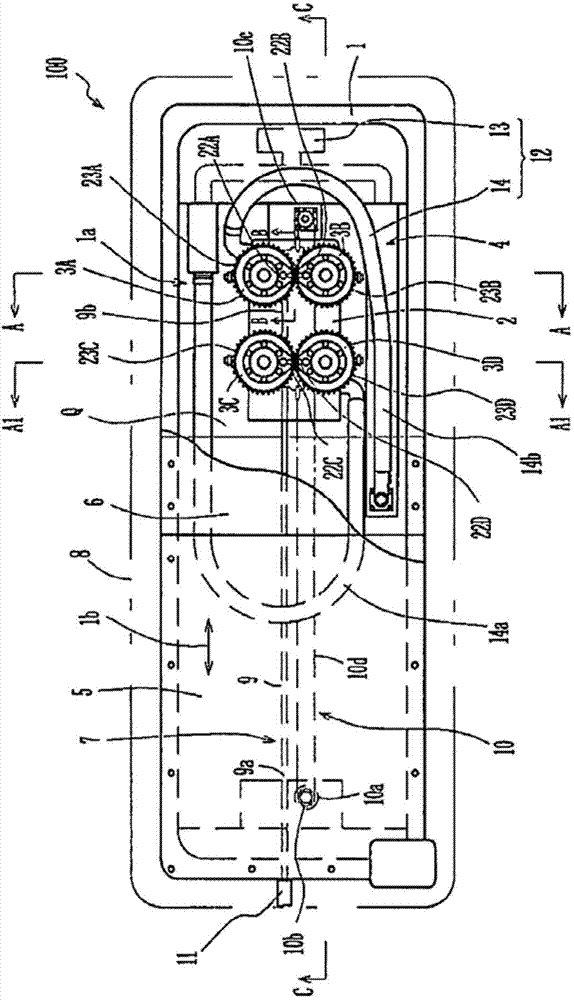

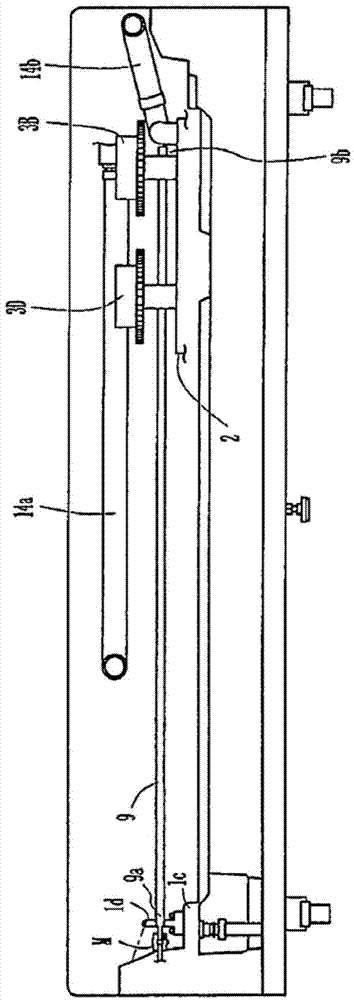

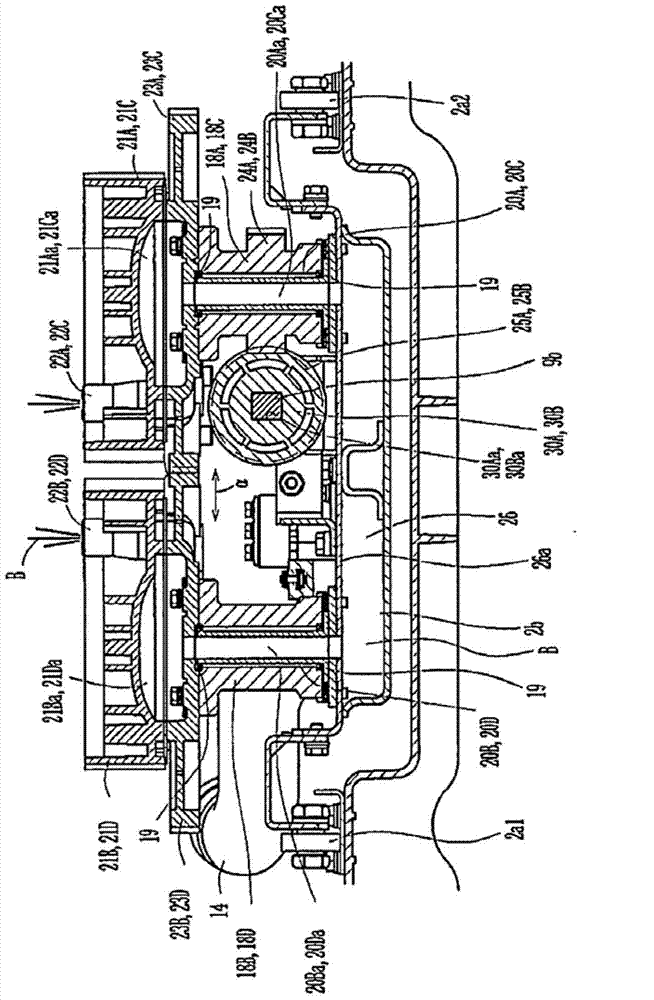

[0029] Next, a massage device according to an embodiment of the present invention will be described with reference to the attached drawings. figure 1 It is a schematic plan view of the massage device according to the embodiment of the present invention. figure 2 is along figure 1 A cross-sectional view of line C-C. image 3 is along figure 1 Partial sectional view of line A-A. Additionally, along the figure 1 The partial cross-sectional view of line A1-A1 is also with image 3 same. Figure 4 It is a partial sectional view of one end side of the shaft. Figure 5 is along figure 1 Partial sectional view of line B-B. Image 6 Yes Figure 5 An enlarged view of the main part. Figure 7 It is a schematic diagram of the structure used to switch the injection part.

[0030] The massage device 100 includes a liquid tank 1 , a moving trolley 2 , first to fourth jetting units 3A to 3D, a jetting liquid supply unit 4 , a flexible sheet 5 , a flexible reinforcing belt 6 , a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com