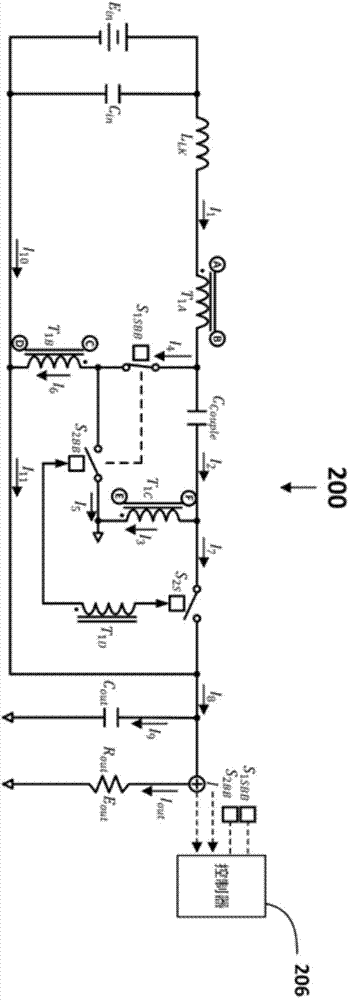

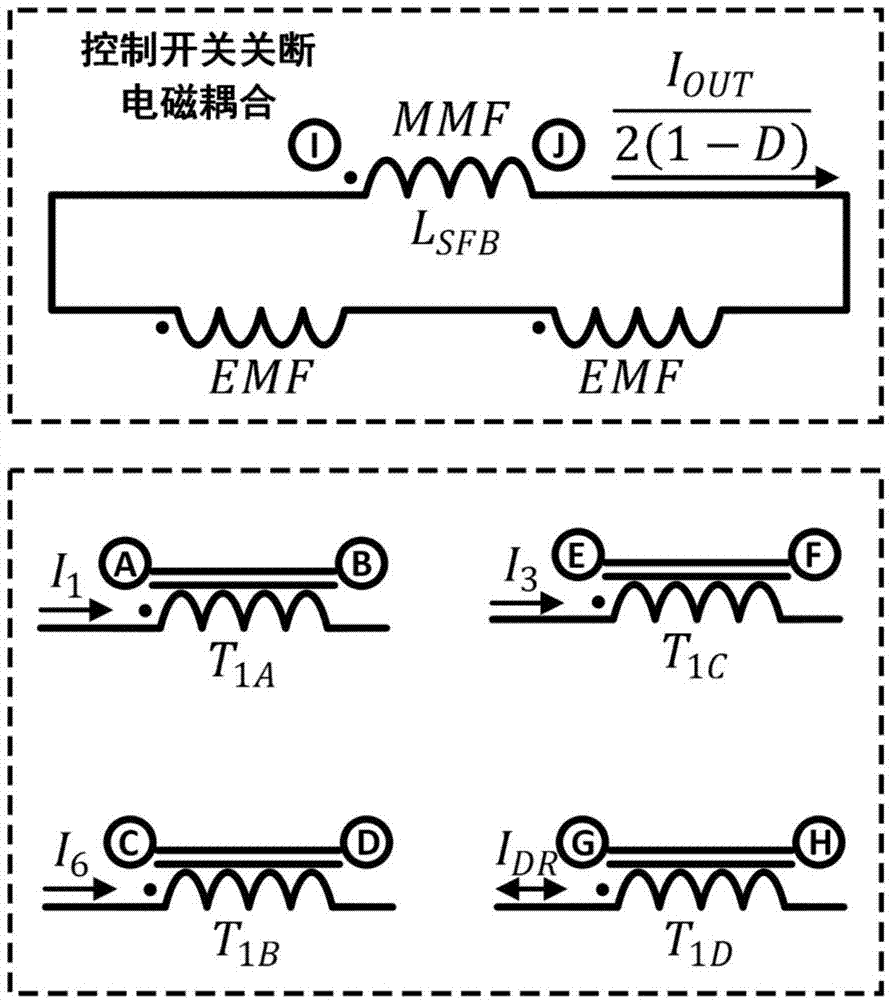

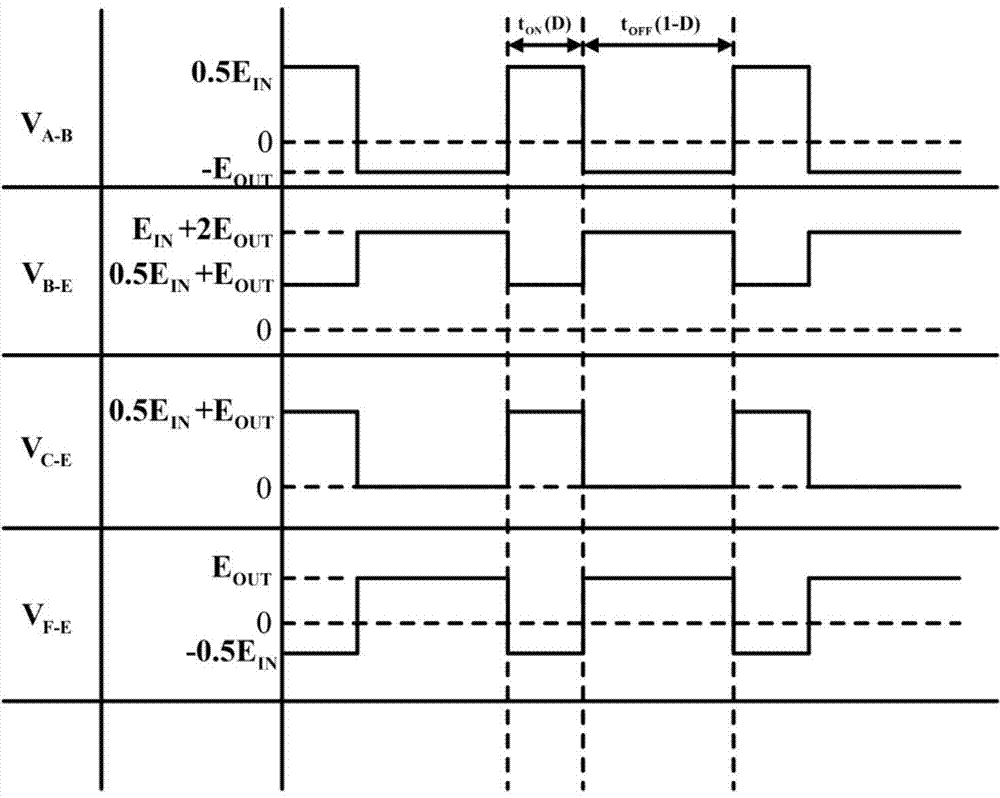

SEPIC feed buck-boost converter

A buck-boost converter and power feeding technology, which is applied in the direction of high-efficiency power electronic conversion, no intermediate conversion to AC conversion equipment, DC power input conversion to DC power output, etc., can solve the problem of large output ripple and limit application and promotion , Converter drive logic complexity and other problems, to reduce input current/voltage ripple, suppress switch resonance phenomenon, reduce output EMI effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] The following description is not intended to be limiting, but merely for the purpose of describing the general principles of the exemplary embodiments. The scope of the present invention should be determined with reference to the claims.

[0038] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, those of ordinary skill in the art need not be employed in the specific details to practice the present invention. In other instances, well-known materials or methods have not been described in detail to avoid obscuring the present invention.

[0039] References throughout this specification to "one embodiment," "an embodiment," "an example," or "an example" mean that a specific feature, structure, or characteristic described in connection with the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com