Powder sample making mould assembly in X-luminoscope

A sample preparation mold and fluorescence instrument technology, applied in the field of experimental equipment, can solve the problems of easy damage of samples, inconsistent sample content, and size error of the inner diameter of the sample ring, so as to ensure high consistency, improve experimental accuracy, and reduce measurement errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The mold assembly for powder sample preparation of the present invention will be further explained below in conjunction with the accompanying drawings and examples.

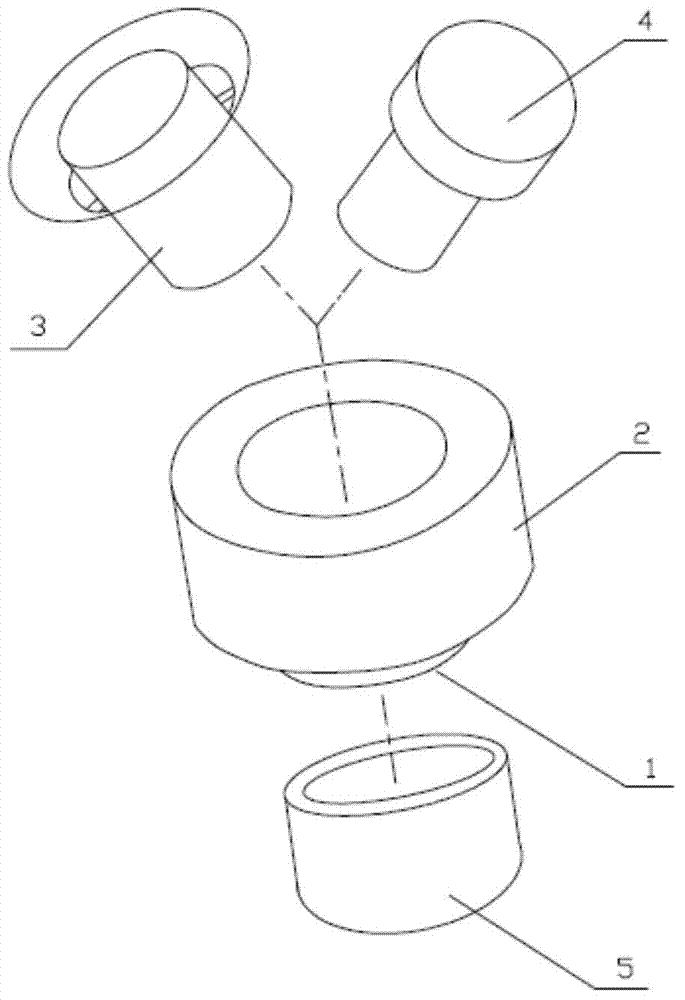

[0019] Such as figure 1 As shown, a powder sample preparation mold assembly in an X-ray fluorescence instrument includes a base 1 , a fixing seat 2 , a sample cup 3 , a pressure sleeve 4 and a sample return sleeve 5 .

[0020] The base 1 is in the shape of a T-shaped boss, and the cylinder at the convex end of the base 1 is socketed with the fixed seat 2. The fixed seat 2 is formed by a through hole arranged inside the cylinder, and the diameter of the through hole matches the diameter of the convex end of the base 1.

[0021] The sample cup 3 is composed of a ring sleeved on the outside of the hollow cylinder and connected by three pillars. The outer diameter of the hollow cylinder is smaller than the diameter of the through hole of the holder 2. Matching, the diameter of the other end of the ring is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com