Dynamic weighing method for high precision underground load-haul-dump machine

A technology of dynamic weighing and underground shoveling, which is applied in the direction of weighing, measuring devices, instruments, etc., and can solve the problems of complex process and lack of theoretical basis for physical analysis in the correction method of speed compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The dynamic weighing method of high-precision underground scraper of the present invention, its preferred embodiment is:

[0026] Weighing is performed by the following formula:

[0027] m = K 1 P 1 + K 2 P 2 + K 3 ( dθ dt ) 2 + K 4 · d 2 θ dt 2 + c ;

[0028] In the formula:

[0029] m is the material mass;

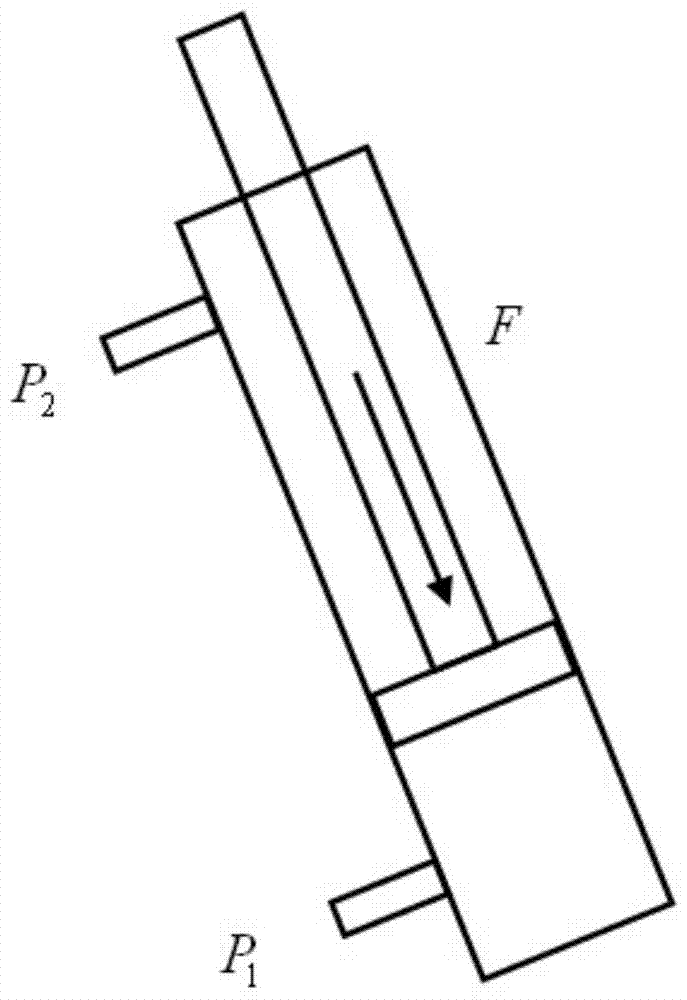

[0030] P 1 ,P 2 are the oil pressure at both ends of the lift cylinder;

[0031] θ is the hinge center of boom and frame (O...

specific Embodiment

[0055] 1) Device:

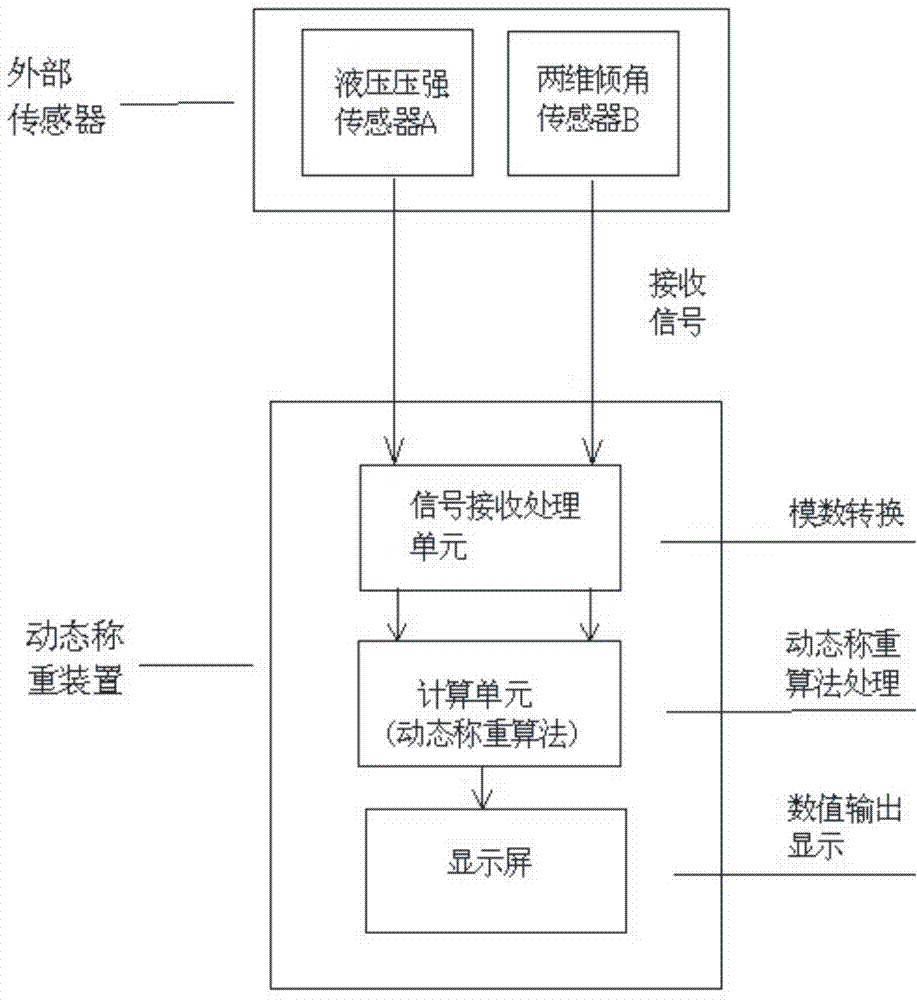

[0056] Use a pressure sensor to measure the inlet and outlet oil pressure of the boom to express the value F; use a two-dimensional inclination sensor to measure the vertical and horizontal angle values θ and γ respectively; use a controller for dynamic weighing calculation; use a display screen for weighing display of re-results. Such as figure 1Shown is a schematic diagram of the workflow of the dynamic weighing method.

[0057] 2) Algorithms

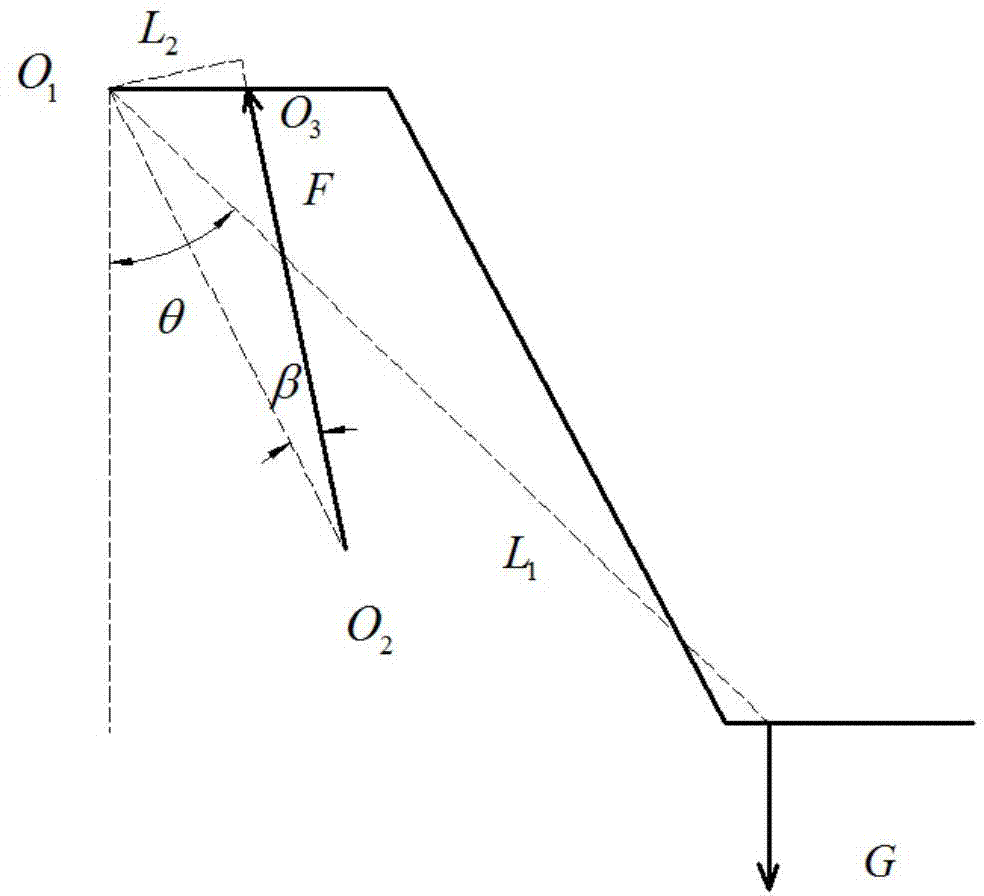

[0058] The working mechanism of the underground scraper and the wheel loader are similar. The mechanical model of the working mechanism of the loader is used for reference, and the mechanical analysis and modeling of the working mechanism of the underground scraper is carried out. See figure 2 , deduce the general calculation formula of ore quality:

[0059] m = F · | O 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com