Intelligent induction type sensor

An inductive sensor technology, applied in the field of sensors, can solve problems such as numerous assembly and debugging steps, switch point offset, and inability to realize industrial control automation and intelligence, so as to facilitate networked control, improve production efficiency, and protect against burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

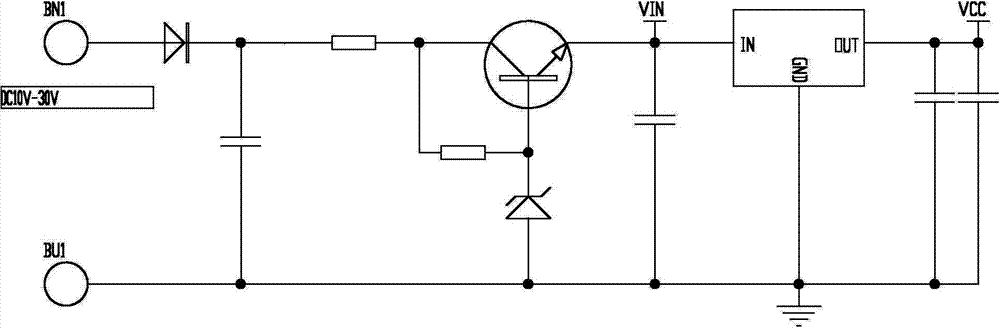

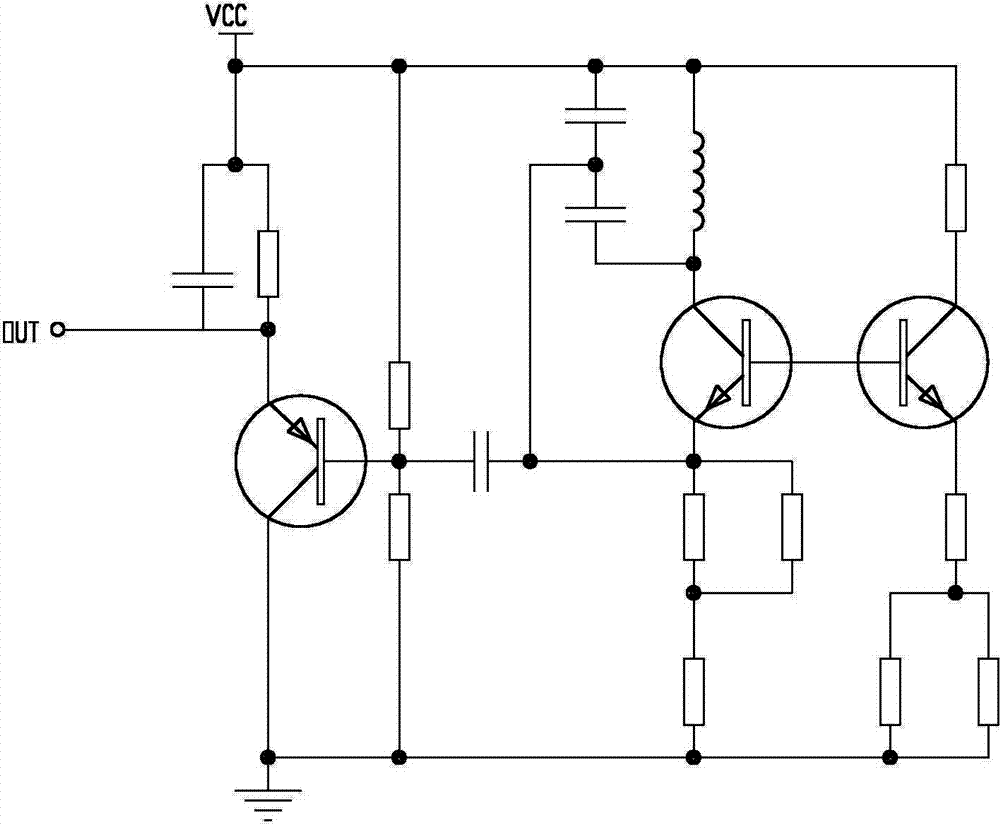

[0025] An intelligent inductive sensor comprising figure 1 shown in the existing power circuit and figure 2 The existing capacitive three-point oscillator circuit shown in also includes image 3 The single-chip microcomputer IC, input circuit 1 and output circuit 2 shown in , the single-chip microcomputer IC is respectively connected with the original output signal line of the capacitor three-point oscillation circuit, input circuit 1 and output circuit 2, and the input circuit 1 and output circuit 2 are connected through the communication bus 4 is connected with the external control board 3 .

[0026] The single-chip microcomputer IC is used to realize the switching between the data transmission function and the logic output function.

[0027] The input circuit 1 is used for data transmission, and its on-off is controlled by the signal sent by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com