Ring-inlaid reducing rubber hose

A technology of rubber hose and rubber pipe, which is applied in the direction of pipeline connection layout, pipe/pipe joint/fitting, passing components, etc., and can solve problems such as difficult connection into pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

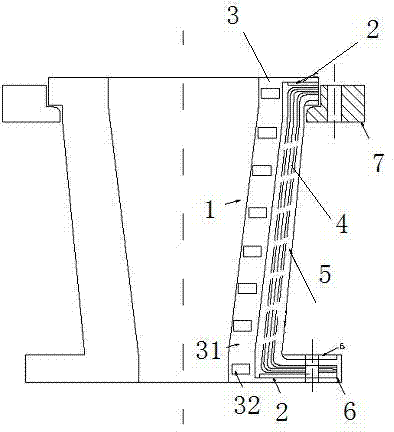

[0012] A kind of rubber hose with embedded ring, see figure 1 , It includes a rubber pipe 1 and flanges 2 arranged at both ends of the rubber pipe. The rubber pipe 1 includes an inner liner 3, a reinforcing layer 4 and an outer covering 5 from the inside out. The inner liner is laid on the entire pipeline including the connector part. The rubber hose inner lining 3, the rubber material of the outer coating 5 and the fiber material of the reinforcing layer 4 extend in the vertical direction along the circumference at both ends of the rubber pipe, and form the flange 2 together with several ring-shaped metal sheets 6. The flange has a rotating flange 7. The inner lining layer 3 contains a plurality of wear-resistant rings 32 made of alloy steel embedded in the rubber compound 31.

[0013] The lumen of the invention increases or decreases from one end to the other end, and is tapered. The wear-resistant ring made of alloy steel embedded in the inner liner has a width of 20-30mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com