Ceramic valve

A technology of ceramic valve and casing, applied to ceramic valve. It can solve the problems of low production yield, solenoid valve and switching valve can not work, can not be flushed, etc., to achieve the effect of improving service life, reducing pressure and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

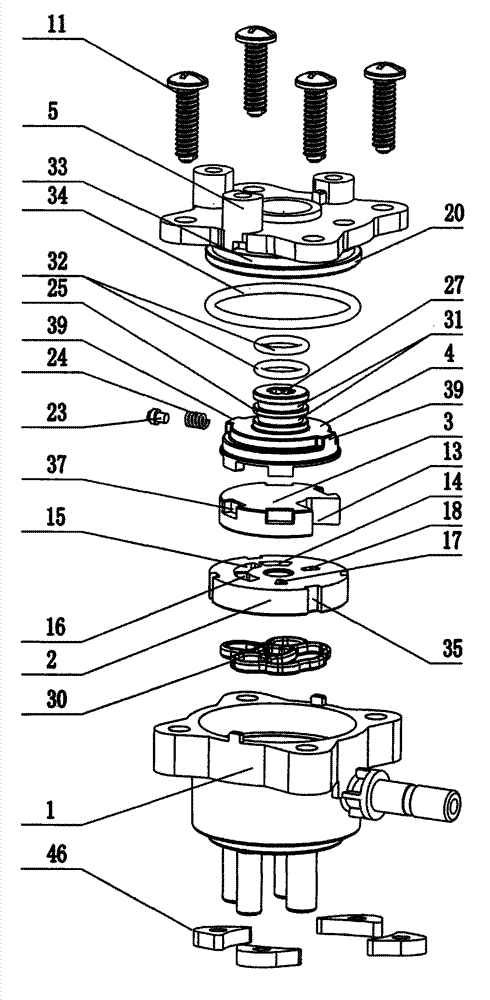

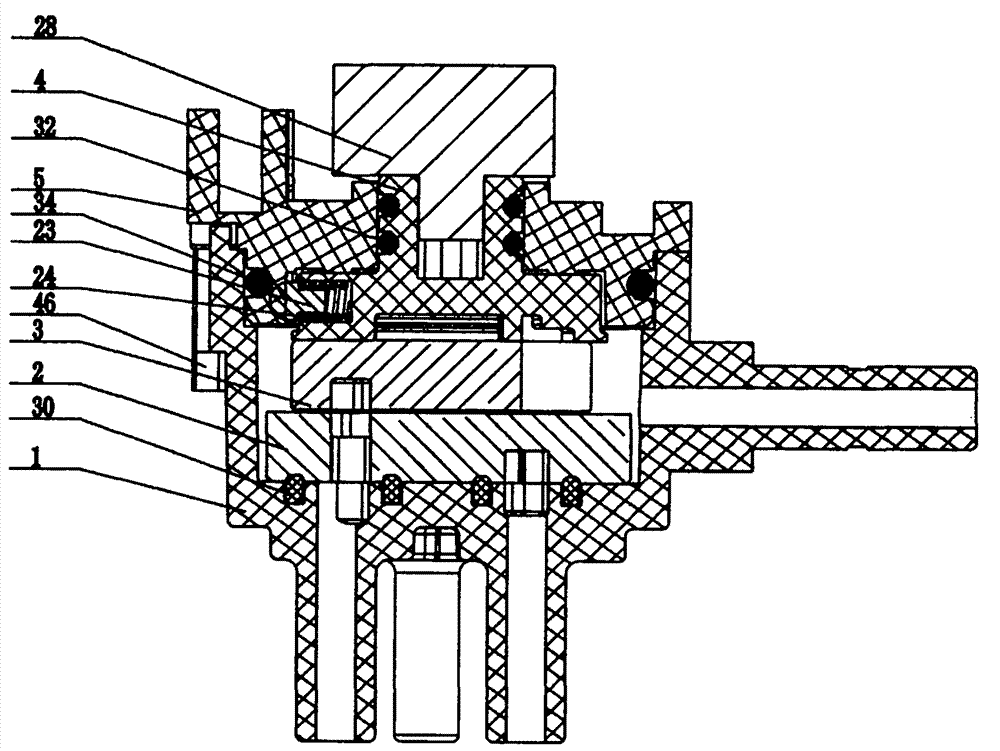

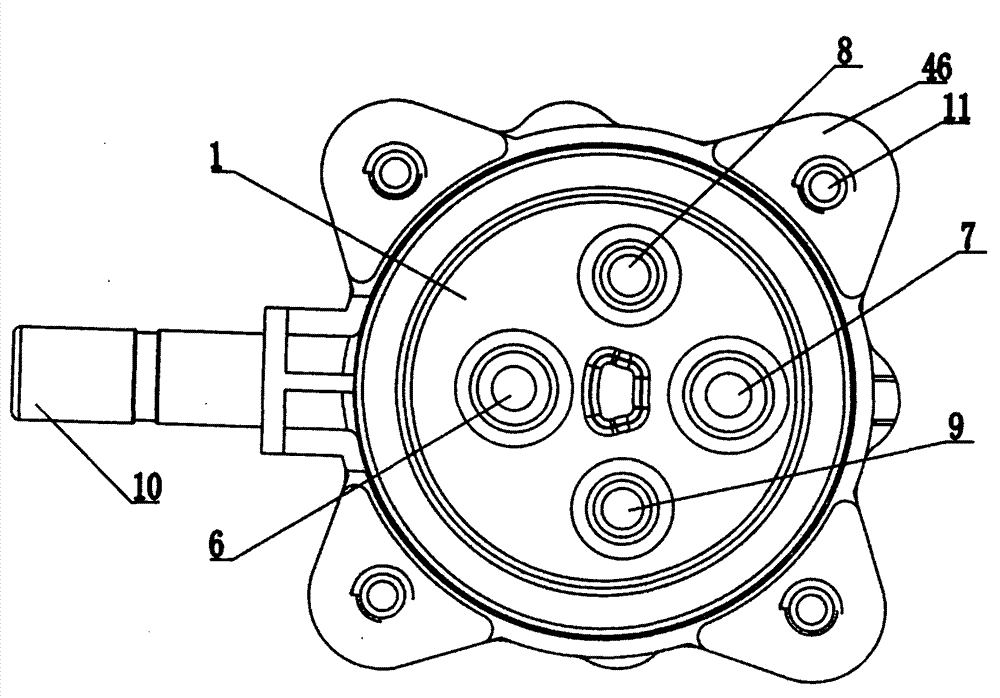

[0037] As an embodiment of the ceramic valve of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8As shown, it includes a housing 1, a fixed piece 2, a moving piece 3, a dial 4 and a gland 5. The bottom surface of the housing 1 is provided with a cold water outlet pipe 6, a hot water inlet pipe 7, a first cleaning pipe 8 and The second cleaning pipe 9 is provided with a cold water inlet pipe 10 on the side wall of the housing 1, the fixed piece 2 is arranged inside the housing 1, and is positioned with the housing 1 on the radial upper limit, and the The moving piece 3 is arranged above the fixed piece 2, the dial 4 is arranged above the moving piece 3, and is positioned on the radial upper limit with the moving piece 3, and the gland 5 is arranged on the dial 4 above, connected with the housing 1 by bolts 11, and then fixed by arc nuts 46, the lower surface of the moving piece 3 is provided with ...

Embodiment 2

[0048] As an embodiment of the ceramic valve of the present invention, such as Figure 9 and Figure 10 As shown, the difference from Embodiment 1 is that in this embodiment, the ceramic valve also includes a motor 41, a driving wheel 42 and a driven wheel 43, and a fixed rod 25 is arranged on the upper surface of the dial 4, and the The gland 5 is provided with a socket 26, the upper end of the fixed rod 25 is inserted into the socket 26, the center of the fixed rod 25 is provided with a slot 27, and the driven wheel 43 is located in the slot 27 , the driving wheel 42 is connected to the output end of the motor 4, and the driving wheel 42 and the driven wheel 43 are meshed. The drive wheel 42 and the driven wheel 43 are provided with a gear box 44 outside, the gear box 44 is fixed on the upper surface of the gland 5 by two self-tapping screws 45, and the motor 41 is fixed on the upper surface of the gland 5 by two self-tapping screws. 47 is fixed on the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com