Hanging packer for horizontal well multistage fracturing

A technology for hanging packers and horizontal wells, which is applied in the directions of sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as poor isolation ability, complex mechanism, and lack of large torque, and achieve the goal of working The effect of high sealing pressure, simple and compact mechanism, and low operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

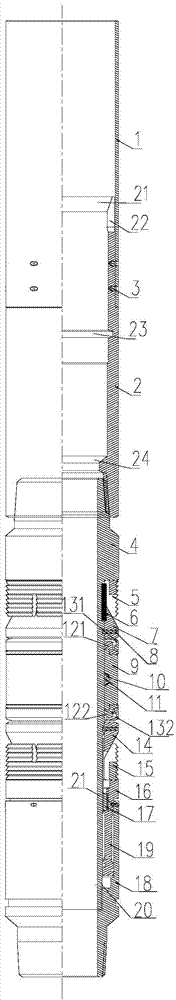

[0021] see figure 1 , a suspension packer for multi-stage fracturing in horizontal wells, comprising an upper joint 2, a central pipe 4 and a lower joint 18 sequentially connected from top to bottom, and a setting mechanism and a suspension mechanism are set outside the central pipe 4 and a sealing mechanism; the sealing mechanism includes a rubber cylinder 9, an upper pressure ring 121 is provided at the upper end of the rubber cylinder 9, a lower pressure ring 122 is provided at the lower end of the rubber cylinder 9, and a lower pressure ring 122 is provided at the upper end of the rubber cylinder 9, The middle part of the inner wall is provided with a support ring 10, an upper cone 7 is arranged above the upper pressure ring 121, and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com