Novel deodorization floor drain core

An anti-odor and floor drain technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of short service life, poor sealing effect, inability to deodorize, and easy blockage of water-sealed floor drains. Guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

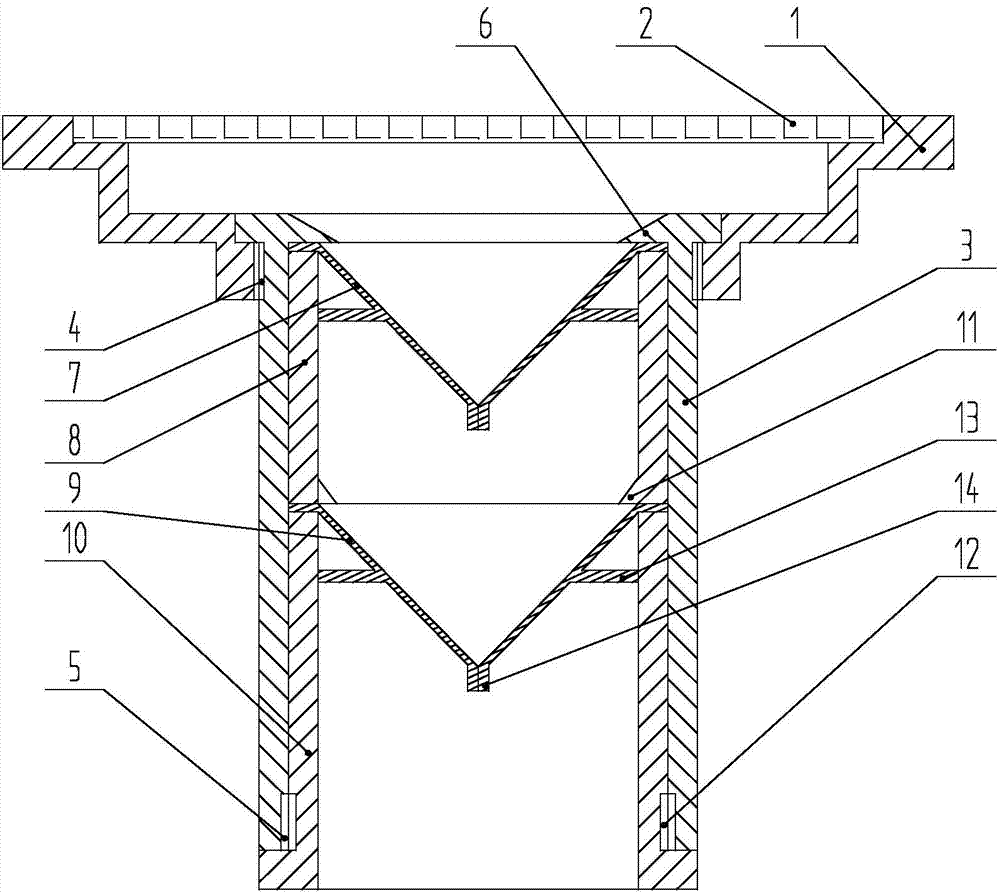

[0018] Such as figure 1 As shown, the present invention includes an upper cover plate 1, a filter screen 2, and a core tube 3. The upper side of the upper cover plate 1 is fitted with a filter screen 2, a core tube 3 is provided below the filter screen 2, and an upper end of the outer side of the core tube 3 is provided. Thread 4, the lower end of the inner side is provided with lower thread 5, the core barrel 3 is connected with the upper cover plate 1 through the upper thread 4, the inner diameter of the upper end of the core barrel 3 is surrounded by a pressure angle 6, and the lower side of the pressure angle 6 is sequentially provided with an upper filter element 7, an upper Inner core barrel 8, lower filter element 9, lower inner core barrel 10, inner presser foot 11 is provided around the inner diameter of the lower end of upper inner core barrel 8, outer diameter of lower end of lower inner core barrel 10 is provided with external thread 12, and upper filter element 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com