Assembled steel-concrete arched bridge t-beam slab

An arch bridge and assembled technology, which is applied in the direction of bridges, arch bridges, bridge parts, etc., can solve the problems of unfavorable transportation, large volume, and poor anti-disturbance performance, so as to save prestress, high anti-disturbance performance, Quality and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

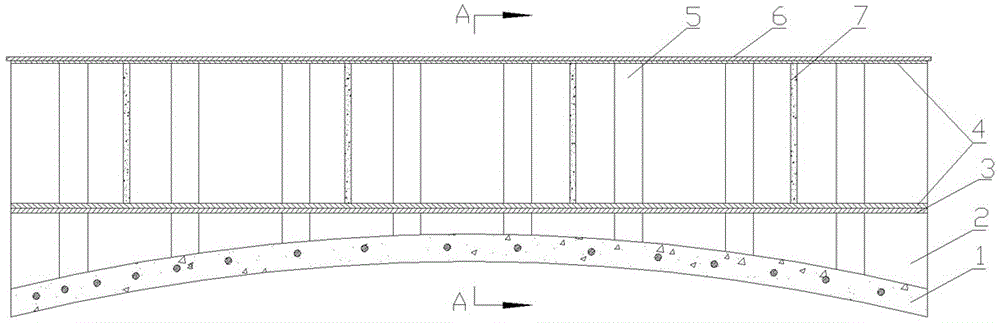

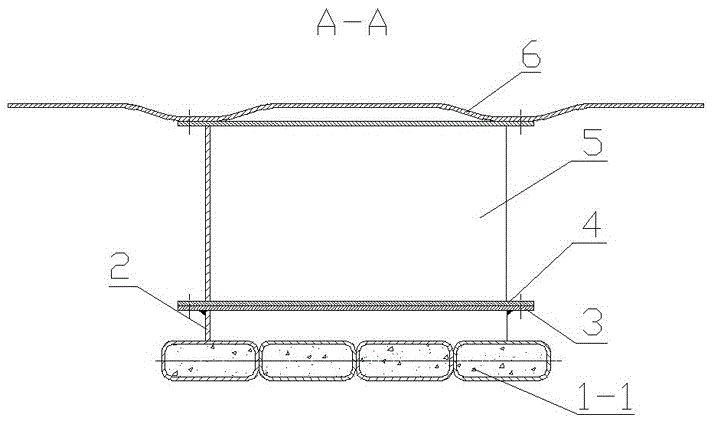

[0013] see figure 1 The structure of the present invention includes a bottom plate 1, a top plate 6, and a corrugated steel web 5 arranged between the bottom plate 1 and the top plate 6. The key technical feature is that the bottom plate 1 is arched at the same height along the bridge direction, On the arched base plate 1, a connecting vertical plate 2 is set, the lower end face of the connecting vertical plate 2 is welded with the arched base plate, the upper end face is a plane and a longitudinal connecting plate 3 with threaded holes or through holes is welded; The upper and lower end faces of the corrugated steel web 5 are respectively welded to the longitudinal steel plate 4, and are respectively connected to the longitudinal connecting plate 3 and the top plate 6 by means of bolts or screw rods, etc., and the corrugated steel web 5 is fastened to the bottom plate 1 and the top plate 6 into one structure.

[0014] Corresponding diaphragms 7 are arranged on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com