Device for high humidity charging coking coal humidity control process

A technology of coking coal and high humidity, applied in coke oven, petroleum industry, energy input, etc., can solve the problems of low moisture-carrying capacity of flue gas, low adjustment ability, complicated control and adjustment, etc. Thermal efficiency, high load adjustment range, good equipment interchangeability

Active Publication Date: 2018-04-10

WUXI YIEN TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There is also the use of coke oven flue gas as a heat carrier, but high-temperature flue gas needs to be transported for a long distance, the energy consumption of the high-temperature fan with large air volume and the heat loss of the flue gas are large, and the flue gas flow rate is limited, the heat capacity is low, and the adjustability is poor.

Secondly, many domestic independent coking enterprises use coke oven gas as the heat source for coke ovens, and the flue gas produced has a high moisture content. Therefore, the flue gas has a low moisture-carrying capacity, which affects the humidity control efficiency.

In addition to the problems of high energy consumption, low adjustment ability, large basic investment, high operating cost, complicated control and adjustment, and large amount of maintenance, the above schemes have problems

When the moisture content of the coal material is too high, many coal humidity control and drying devices will be affected, which will seriously affect the effect and efficiency of the coal humidity control process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

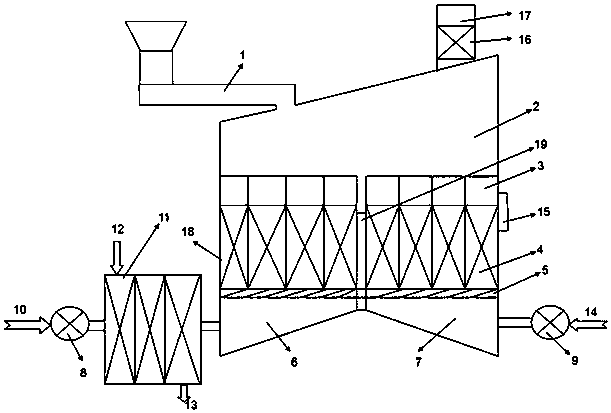

The invention discloses a device for high-humidity furnace-loading coking coal humidity control technology, which comprises a fluidized bed type humidity control machine, and a first fluidized bed type built-in heat control device is arranged side by side in the fluidized bed type humidity control machine. The humidity module and the second fluidized bed type built-in heat and humidity control module, the first fluidized bed type built-in heat and humidity control module is connected in series with an air preheater and a first fluidization fan in series to form a first process loop; The second fluidized bed type built-in heat and humidity control module is connected in series with a second fluidization fan to form a second process loop; the first process loop and the second process loop are connected through an adjustable overflow plate. The present invention adopts a frame structure, and the air preheater and the fluidized bed type humidifier are all modularized combinations, which ensures convenient installation and maintenance of the process device, and multiple modules can be arbitrarily combined into a large process device according to production requirements. Only one backup module is needed to ensure the normal production of the humidity control system, which reduces the scale of the backup equipment of the existing humidity control system.

Description

technical field [0001] The invention relates to the technical field of coking in the coking industry, in particular to a device used in the high-humidity furnace charging coking coal humidity control process. Background technique [0002] Coal humidity control process (CMC) refers to the process of "moisture control of coal for coking and charging furnace". It is developed on the basis of dry coal coking technology. , dehydration, to achieve the adjustment and control of coal moisture. According to the current coking process requirements, the moisture in coal is controlled at about 6%, so as to reduce the energy consumption of the coking process, ensure the stability of coke oven operation, improve the quality of coke or increase the weak The purpose of adding the amount of caking coal and reducing the amount of coking sewage. At the same time, the moisture content of the coking coal in the furnace is reduced, and the bulk density of the coal is increased, which correspondi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10B57/10

CPCY02P20/129

Inventor 惠建明郁鸿凌耿秋红

Owner WUXI YIEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com