Biochemical reactor for bacterial colonies in ship ballast water

A biochemical reactor and ship ballast water technology, applied in chemical instruments and methods, natural water treatment, special compound water treatment, etc., can solve the problems of inconvenient biofilm, short service life, regular maintenance, etc., to achieve Increased efficiency of bioluminescent use, improved economy and reliability, and better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

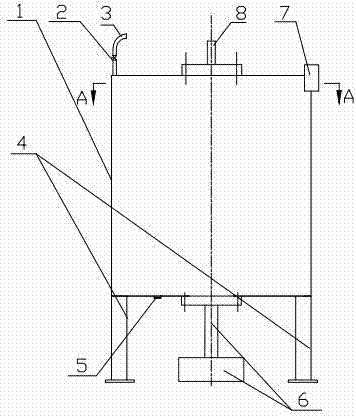

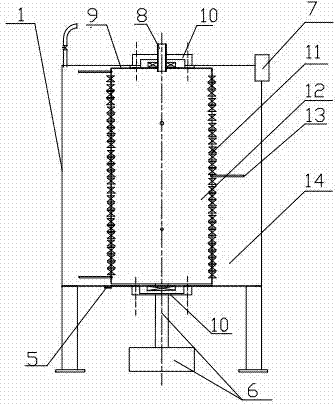

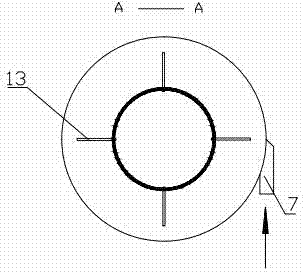

[0023] The present invention specifically relates to a ship ballast water colony biochemical reactor, the biochemical reactor is to provide a luminous biochemical reaction place for bacterial species ATP, luciferase, luciferin and auxiliary agents in the ballast water to realize the mixed reaction of bacteria species The liquid is fully mixed, and the photoelectric sensor is used to conveniently detect the reaction phenomenon. Depend on figure 1 with 2 It can be seen that the reactor specifically includes a cylindrical shell 1 and a vertical rotating body 9 inside the shell 1. The shell 1 is a fixed structure fixed by a base 4 arranged on the end surface of the shell 1; in addition, the rotating body 9 and the The casing 1 is arranged coaxially, and the rotating body 9 is a cylindrical hollow structure with filtering holes 11 distributed on its side, and the rotating body 9 can rotate around the axis of the casing 1 . The inner hollow part of the rotating body 9 is the fungu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com