AGV drive mechanism

A technology for a driving mechanism and a trolley, which is applied to motor vehicles, power units, vehicle components, etc., can solve the problems of complex structure of the driving device, occupy a large space, and the vehicle body is easy to tilt, so as to improve the operation accuracy, work efficiency, and save money. The effect of stable operation of space and body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

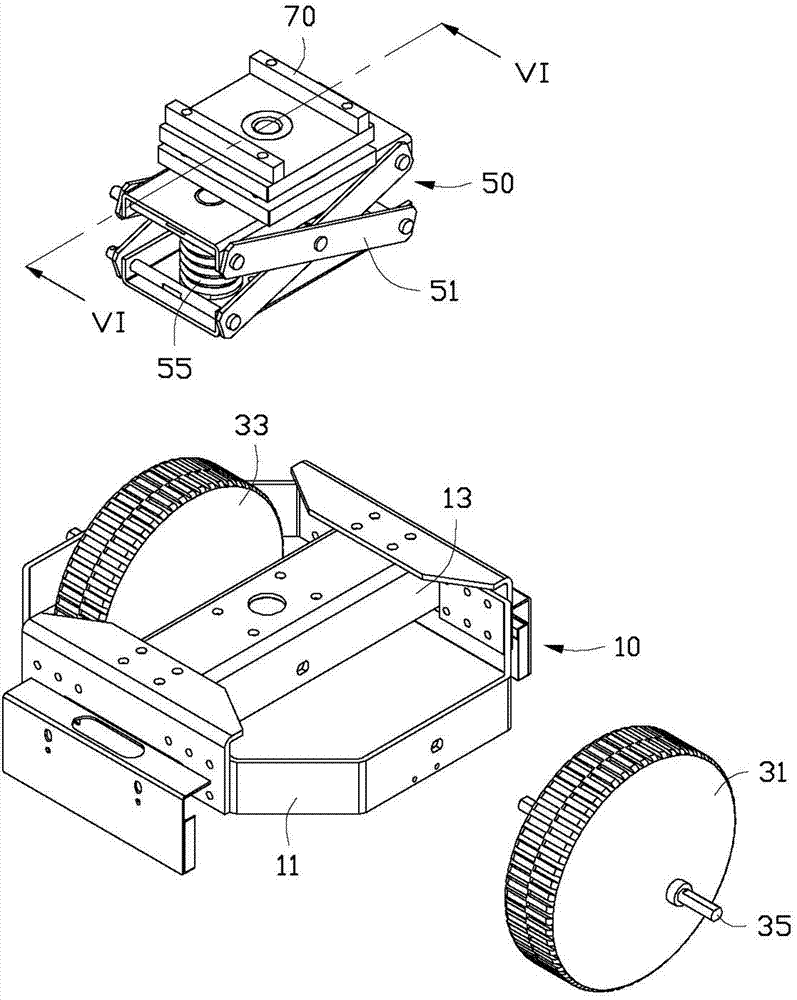

[0015] See Figure 1 to Figure 2 The driving mechanism 100 of the AGV trolley according to the embodiment of the present invention includes a support 10, a driving assembly 30, a buffer assembly 50 and a rotating assembly 70. The drive assembly 30 is in contact with the ground when in use, the support 10 is installed on the drive assembly 30, and the drive assembly 30 can rotate relative to the support 10. The buffer assembly 50 is installed on the support 10. The buffer assembly 50 has a buffer effect on the body of the AGV trolley. The rotating assembly 70 is installed on the buffer assembly 50 for supporting the body of the AGV trolley.

[0016] The support 10 is roughly a frame structure and provides support for the drive assembly 30 and the buffer assembly 50. The supporting member 10 includes a main frame 11 and a supporting board 13 installed inside the main frame 11. The main frame 11 is approximately a closed hollow octagonal frame, and the carrying plate 13 is appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com