A powder recovery device for a 3dp color 3D printer

A technology of 3D printers and recycling devices, which is applied in processing and recycling, manufacturing auxiliary devices, processing and manufacturing, etc., can solve the problems of large dust in the molding environment, and achieve the effects of fast recycling, improved precision, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

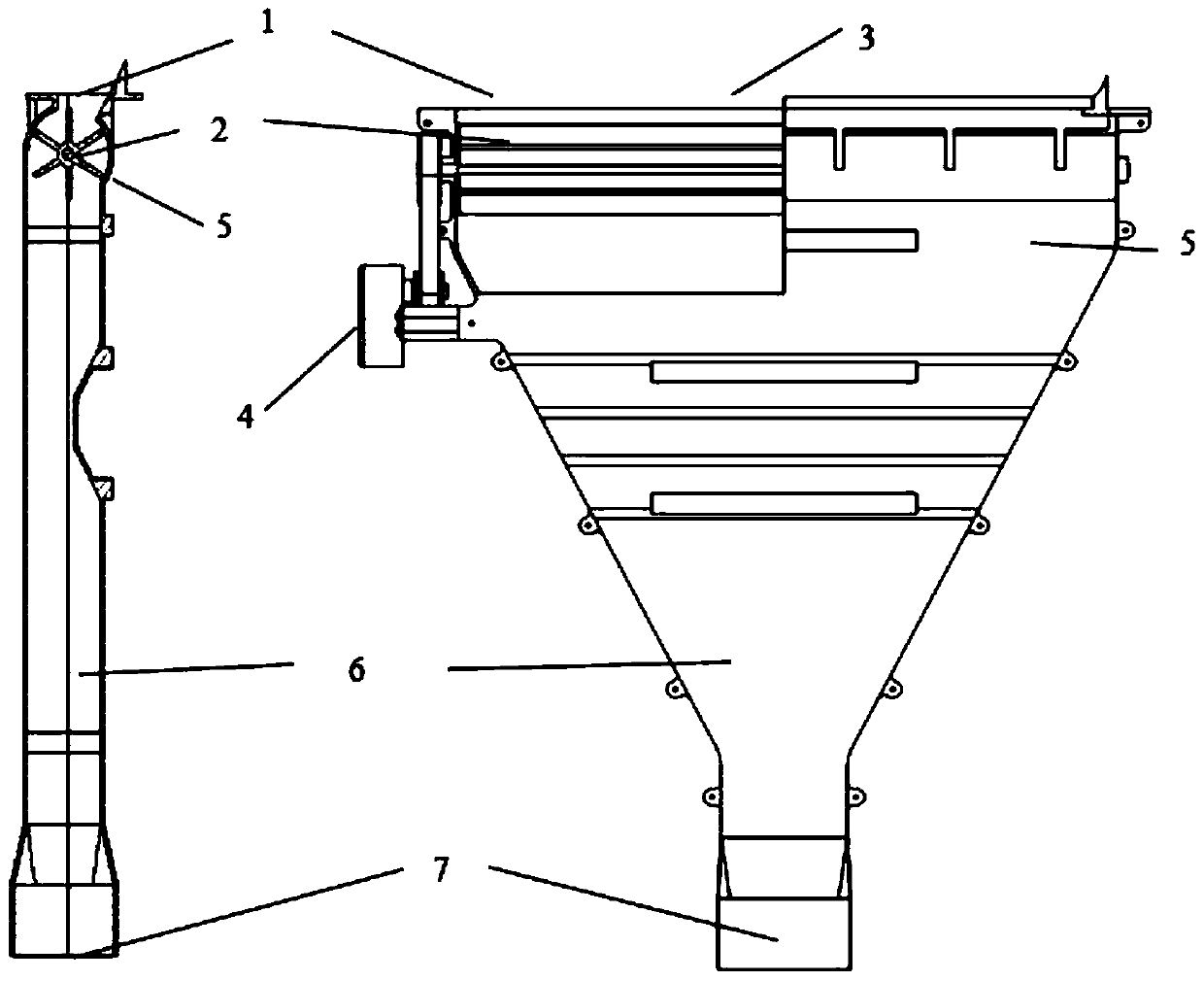

[0014] A 3DP color three-dimensional printer powder recovery device, the device includes: a computer, a powder recovery tank parallel to the forming platform, a dust reduction net is arranged at the notch of the recovery tank, a powder rotary fan and a powder rotary fan are arranged directly below the dust reduction net. The fan rotates under the control of the stepping motor. There are curved slide plates on both sides of the powder rotating fan. Under the control of the computer, the stepping motor controls the powder rotating fan to form 120-degree fan blades. The notch of the recovery tank is facing directly, and keeps a distance of 1mm from the arc-shaped sliding plate. The arc-shaped powder sliding plate is connected to the notch, and the bottom is connected to the recovery powder pipeline. Right below the powder pipeline is the powder recovery box.

[0015] The powder recovery device with powder fan and arc-shaped slide plate structure greatly improves the environment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com