Multifunctional numerically-controlled rear material stopping device

A backgauge and multi-functional technology, which is applied in the field of sheet metal bending, can solve the problems of out-of-sync on both sides of the backgauge and easy material deviation, etc., and achieve the effect of reducing transmission gap, low cost, and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

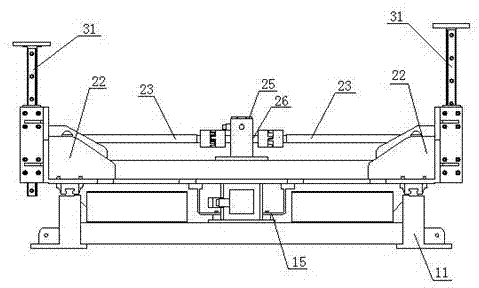

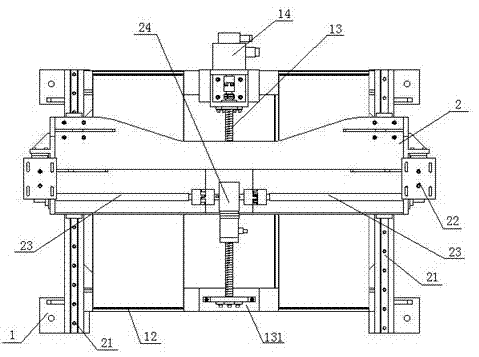

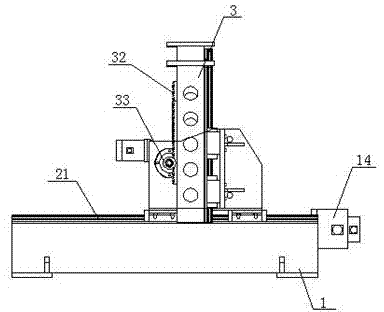

[0029] Such as Figure 1-4 As shown, a numerically controlled multifunctional backgauge device includes an X-axis backgauge 1, an R-axis backgauge 2 installed on the X-axis backgauge, and a Y axis fixedly installed above the R-axis backgauge. Shaft back gauge 3.

[0030] The X-axis backgauge 1 includes a support base 11, a linear guide pair 12 with a slider 121 arranged on the support base 11, an X-axis ball screw 13 fixed by a screw bearing seat 131, and an X-axis ball screw 13 fixed on the X-axis. The servo motor 14 on the ball screw 13, the slider 121 and the X-axis ball screw 13 are fixedly connected through the screw base connecting bracket 15; the screw base connecting bracket 15 is a U-shaped bracket.

[0031] The R-axis backgauge 2 includes a sliding guide rail 21 fixed on the support base 11, an R-axis bearing seat 22 installed on the sliding guide rail 21, and 2 mounted on the same straight line on the R-axis bearing seat 22. A R-axis gear shaft 23 and a servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com