Vacuum frozen-dried potato noodle as well as preparation method of vacuum frozen-dried potato noodle and instant food

A technology of vacuum freeze-drying and potato noodles, which is applied in the field of food processing, can solve the problem of fewer food types, achieve the effects of less loss of nutrients, reduce rehydration time, and increase nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

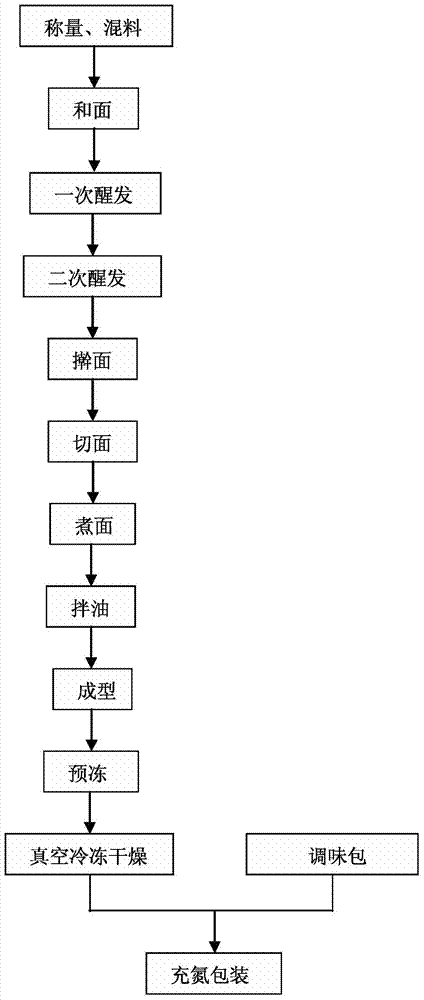

Method used

Image

Examples

Embodiment 1

[0054] (1) Formula: Flour ratio (wheat flour 55g, potato flour 30g, gluten powder 2g), water 30g, salt 1.0g.

[0055] (2) Kneading dough: put flour and 5.0g of cross-linked starch into the mixing tank and stir evenly, add the weighed salt, 1g of white vinegar, and 0.1g of compound phosphate into water to dissolve, and slowly add water into the flour from the water inlet ; Kneading time 3min.

[0056] (3) One-time proofing: proof the loose dough at 25°C for 1 hour.

[0057] (4) Second proofing: press the loose dough into noodle blocks (generally pressing 5-6 times), proofing at 25°C for 10 hours.

[0058] (5) Rolling noodles: Roll the proofed noodles to a thickness of 0.5mm, and sprinkle dry flour during the rolling process to prevent sticking.

[0059] (6) Noodle cut: Sprinkle dry flour on the noodle strip, then cut it into raw noodles with a width of 1.5mm.

[0060] (7) Cooking noodles: Put the raw noodles into boiling water, cook for 20 seconds on medium heat, and remove ...

Embodiment 2

[0068] (1) Formula: flour ratio (wheat flour 45g, potato flour 50g, gluten powder 6g), water 40g, salt 2.5g.

[0069] (2) Kneading dough: Put flour and 14.0g of cross-linked starch into the mixing tank and stir evenly. Add the weighed salt, 3g of white vinegar, and 0.3g of compound phosphate into water to dissolve, and slowly add water into the flour from the water inlet. ; Kneading time 7min.

[0070] (3) One-time proofing: proof the loose dough at 30°C for 3 hours.

[0071] (4) Second proofing: press the loose dough into dough pieces, proofing at 30°C for 16 hours.

[0072] (5) Rolling noodles: Roll the proofed noodles to a thickness of 1.5mm, and sprinkle dry flour during the rolling process to prevent sticking.

[0073] (6) Noodle cutting: Sprinkle dry flour on the noodle strips, then cut them into raw noodles with a width of 2.5 mm.

[0074] (7) Cooking noodles: Put the raw noodles into boiling water, cook for 40 seconds on medium heat, and remove immediately.

[0075...

Embodiment 3

[0082] (1) Formula: flour ratio (wheat flour 60g, potato flour 38g, gluten 5g), water 35g, salt 1.0g.

[0083] (2) Kneading dough: put flour and 10g of cross-linked starch into the mixing tank and stir evenly, add weighed salt, 3g of white vinegar, and 0.2g of compound phosphate into water to dissolve, and slowly add water into the flour from the water inlet; The kneading time is 7 minutes.

[0084] (3) One proofing: proof the loose dough at 30°C for 2 hours.

[0085] (4) Second proofing: press the loose dough into dough pieces, proofing at 30°C for 14 hours.

[0086] (5) Rolling noodles: Roll the proofed noodles to a thickness of 0.5mm, and sprinkle dry flour during the rolling process to prevent sticking.

[0087] (6) Noodle cut: Sprinkle dry flour on the noodle strip, then cut it into raw noodles with a width of 1.5mm.

[0088] (7) Cooking noodles: Put the raw noodles into boiling water, cook for 40 seconds on medium heat, and remove immediately.

[0089] (8) Mixing wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com