Reinforcing material for preventing punching shear, and construction method using same for areas where pillars join with slabs and spread foundations

A technology for strengthening components and construction methods, which is applied in the direction of basic structure engineering, building components, building reinforcements, etc., can solve problems such as increasing connection operations, increasing workload, and impact on the safety of plate-pillar joints, achieving reduction in thickness, The effect of reducing reinforcement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

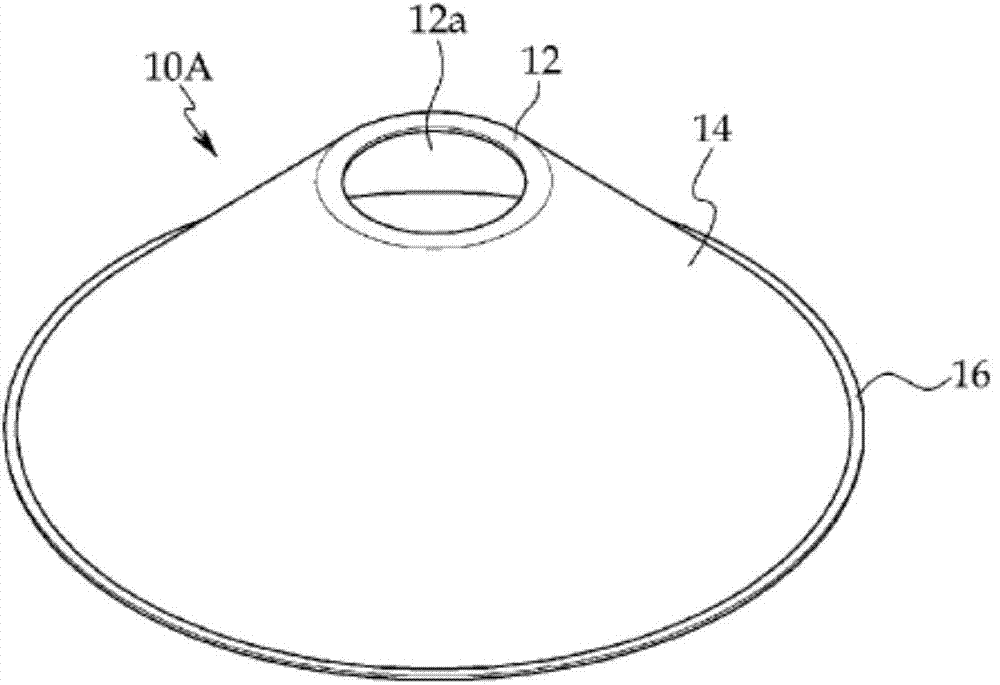

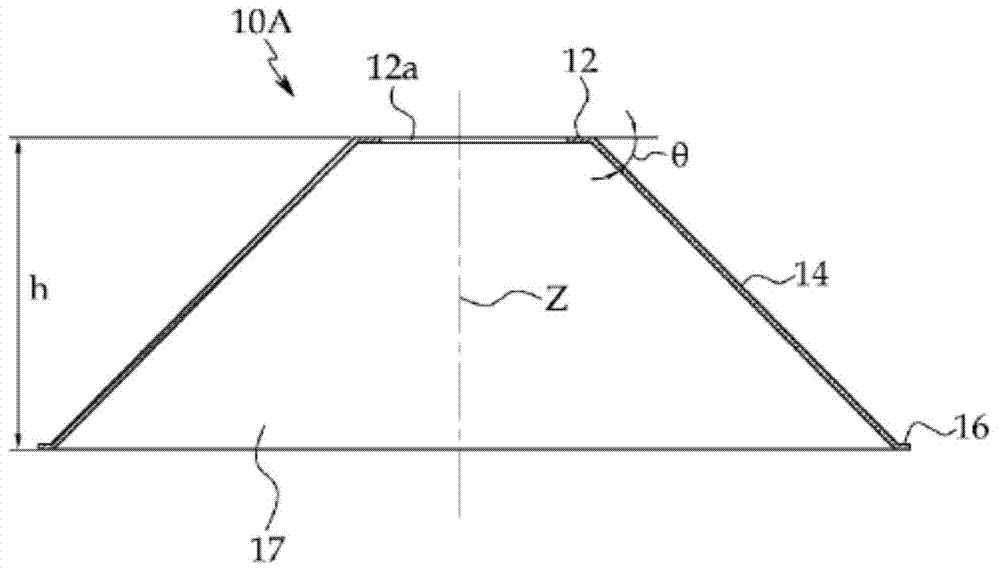

[0071] Figure 1a and Figure 1b In the figure, there is shown a punching resistance reinforcing member 10A according to the first embodiment. The punching resistance reinforcing member 10A is made of a metal material. For example, the punching resistance reinforcing member 10A can be made of steel. The punching resistance reinforcing member 10A is formed with: an upper disk 12 having a circular shape and a predetermined thickness; a skirt portion 14 extending from the outer periphery of the upper disk 12 and Gradually expand the cross-sectional area to the bottom, the skirt portion 14 determines the height h of the reinforcing member 10A for punching resistance; the concrete filling chamber 17, the concrete filling chamber 17 is hollow and the bottom of the concrete filling chamber 17 is open for Concrete is filled into the skirt portion 14 .

[0072] The thickness of the skirt portion 14 may be formed to be the same as or thicker than that of the upper disk 12 . The skir...

no. 2 approach

[0083] In the second embodiment, the same or equivalent parts as those in the first embodiment are described using the same symbols.

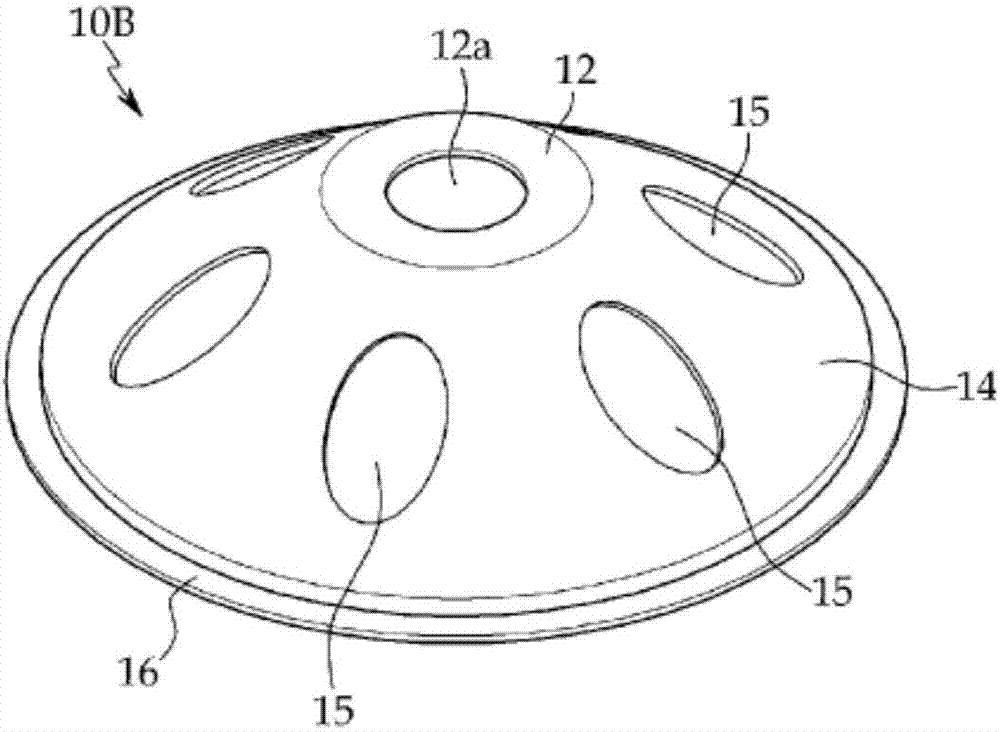

[0084] like Figure 7a and Figure 7b As shown, the punching resistance reinforcing member 10F according to the second embodiment is characterized by comprising: an upper disk 12 having a circular shape and having an upper concrete injection hole 12a in the center; a skirt portion 14, the The skirt part 14 extends from the circumference of the upper disc 12 and gradually expands the cross-sectional area from the top to the bottom; the concrete filling chamber 17 communicates with the upper concrete injection hole 12a and the bottom is open for the skirt The interior of the portion 14 is filled with concrete, and the skirt portion 14 is formed into a hemispherical shape by rotating a curved hypotenuse with a predetermined radius of curvature R around the central axis Z of the upper disc 12 for one revolution.

[0085]At this time, the upper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com