Ion exchange membrane electrolytic cell

An ion exchange membrane and electrolytic cell technology, which is applied in the electrolysis process, electrolysis components, diaphragms, etc., can solve the problems of thin wire penetration, plastic deformation of damaged ion exchange membrane, uneven distance between electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A dimensionally stable electrode manufactured by Japan Permanent Electrode Co., Ltd. was used as the anode, and an active cathode with a nickel microporous mesh substrate was used as the cathode. The dimensions of the reaction surfaces of the anode and the cathode were respectively set to a width of 110 mm and a height of 1400 mm. As the ion exchange membrane, Flemion F-8020 manufactured by Asahi Glass Co., Ltd. was used.

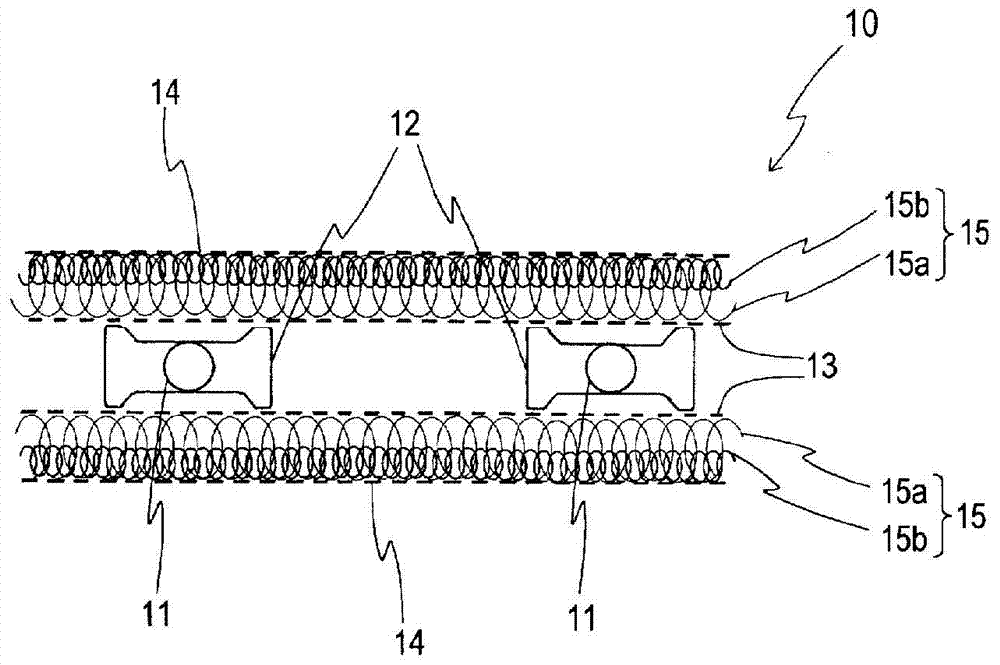

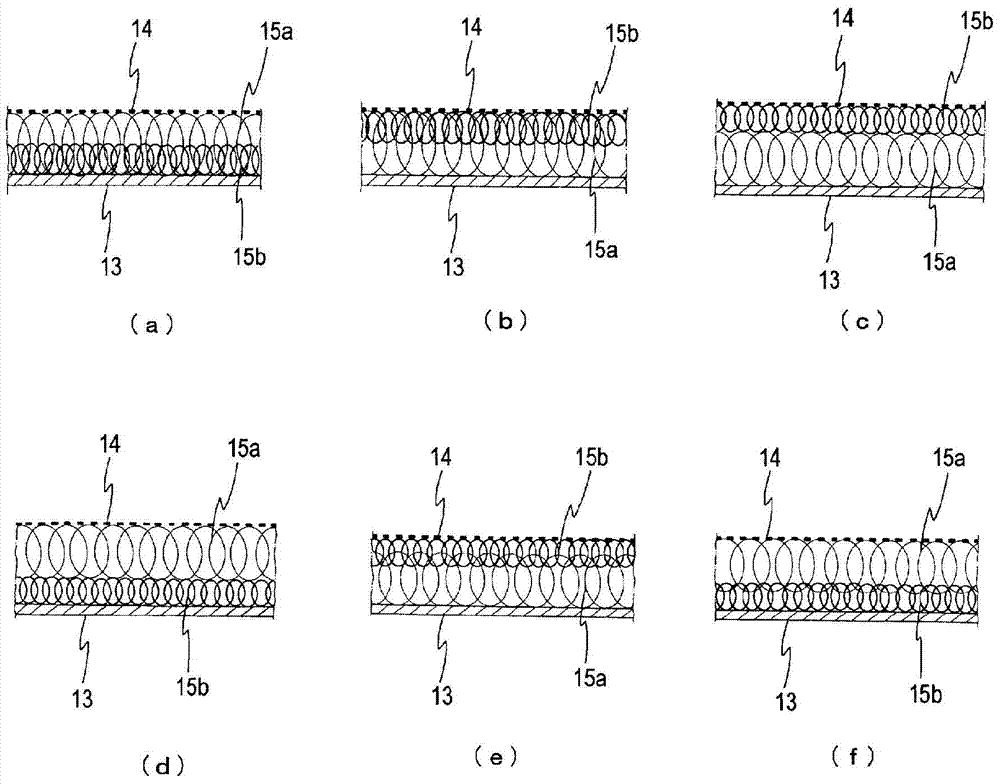

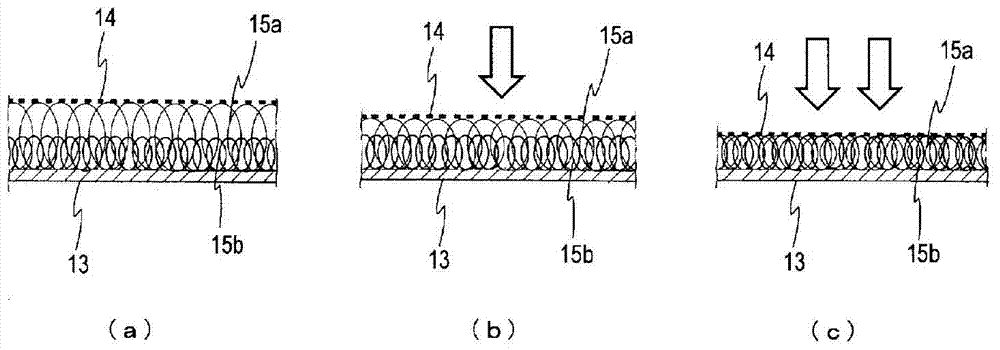

[0054] Furthermore, the wire diameter is 0.17mm and the tensile strength is 620N / m by rolling processing. 2 ~680N / m 2 The nickel wire (NW2201) is made into a coil wire with a width of about 0.5mm. Using the obtained coil wire, a metal coil with a winding diameter of 6.5 mm was produced as a metal coil body with a small reaction force, and a metal coil body with a coil winding diameter of 4.5 mm was produced as a relative Metal coil body with high reaction force. The reaction force ratio of the obtained metal coil body was 0.7. This metal coil bo...

Embodiment 2

[0057] Instead of winding a metal coil body with a large diameter and a metal coil body with a small diameter around a corrosion-resistant frame, the metal coil body with a large diameter and a metal coil with a small diameter Electrolysis was performed under the same conditions as in Example 1 except that a body was inserted between the cathode current collector and the hydrogen generating cathode. In addition, the above-mentioned metal coil body is formed figure 2 The state shown in (a).

Embodiment 3

[0059] With the elastic buffer material made in Example 1 as the negative electrode, utilize the brush plating method (current 0.5A, every Plated 1dm 2 5 minutes), the ion-exchange membrane side surface of each metal coil body constituting the elastic cushioning material was plated with platinum. Electrolysis was performed under the same conditions as in Example 1, except that the obtained platinum-plated elastic buffer itself was used as a cathode and inserted between the cathode current collector and the ion-exchange membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com