Self-cutting follow current lightning arrester

A lightning arrester and self-cutting technology, which is applied in the electric power field, can solve the problems of high price of metal oxide valves, increase the weight of lightning arresters, hidden safety hazards, etc., and achieve the effect of eliminating the phenomenon of out-of-control thermal balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

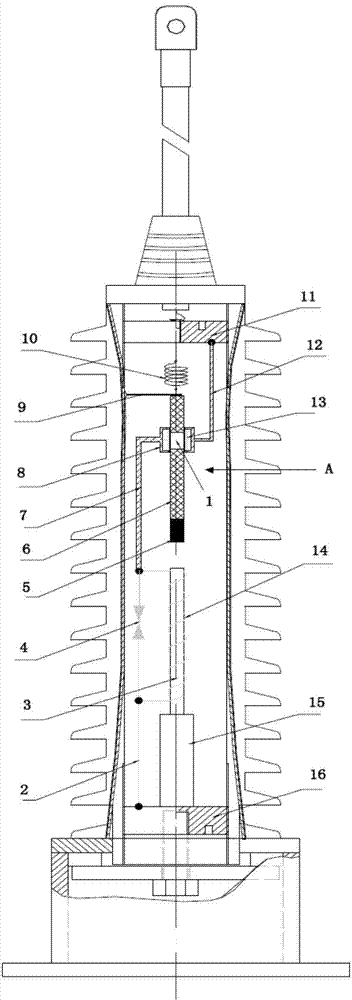

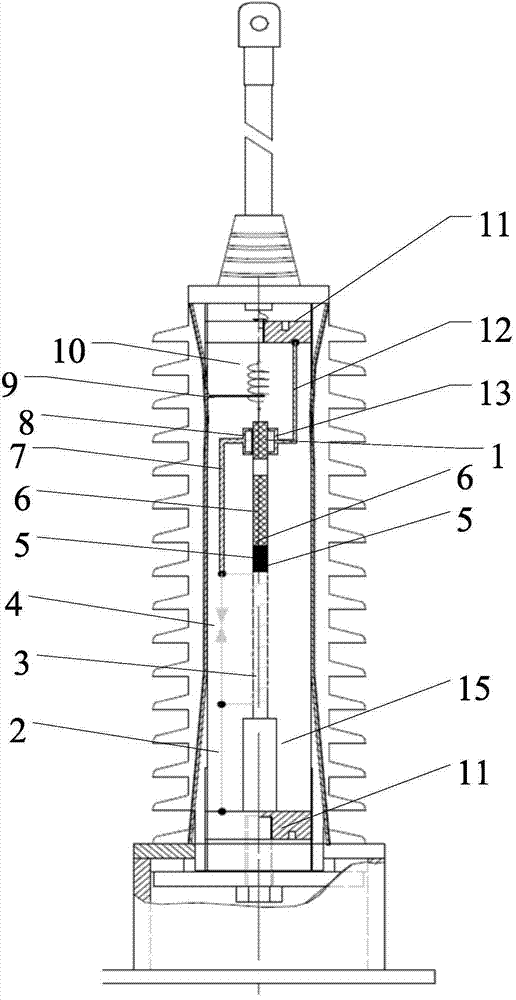

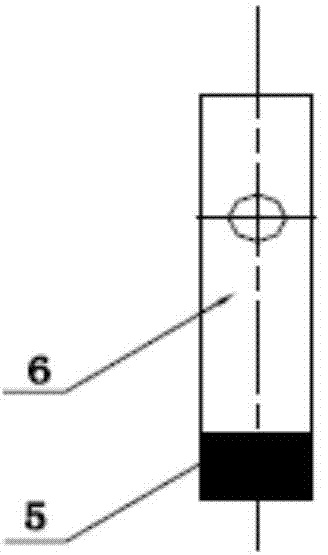

[0016] A freewheeling arrester capable of self-cutting, comprising an outer rubber sleeve of the arrester, an insulating cylinder is arranged inside the outer rubber sleeve of the lightning arrester, and an upper electrode 11 and a lower electrode 16 are respectively arranged above and below the inside of the insulating cylinder. The outer rubber sleeve, the insulating cylinder, the upper electrode 11 and the lower electrode 16 form a sealed chamber, which is characterized in that: the sealed chamber is provided with an upper wire 12, a middle wire 7 and a lower wire 2, and the upper wire 12 is connected to the upper On the electrode 11, the lower conductor 2 is connected to the lower electrode 16, a main discharge gap 1 is connected in series between the upper conductor 12 and the middle conductor 7, and an auxiliary discharge gap 1 is connected in series between the middle conductor 7 and the lower conductor 2. Gap 4; the main discharge gap 1 is made up of two hemispherical e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com