Waterproof wire rod processing method

A processing method and wire technology, which are used in dust/splash/leak/waterproof/fireproof connections, circuit/collector parts, electrical components, etc., can solve problems such as poor waterproof performance, and achieve easy realization. , the effect of reducing costs and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

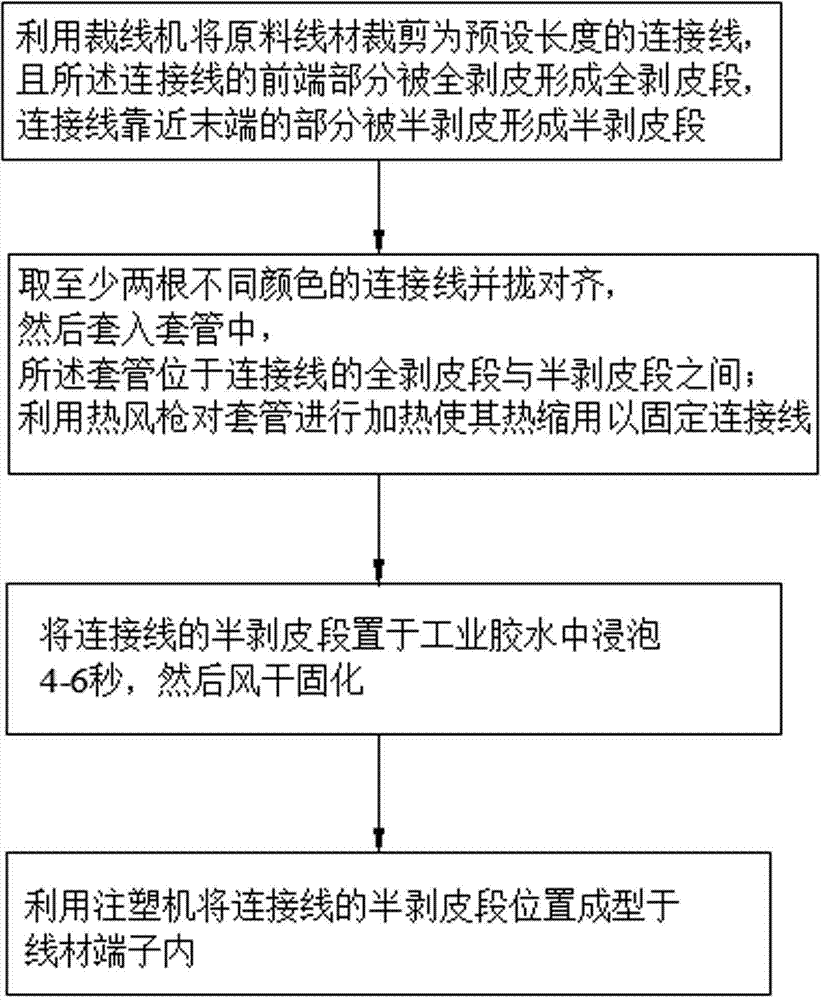

[0025] Embodiments of the present invention, such as figure 1 As shown, a waterproof wire processing method, the waterproof wire includes at least two connecting wires of different colors set in the wire terminal, the method includes the following steps:

[0026] Step S1. Use a wire cutting machine to cut the raw wire into a connecting line of a preset length. In this embodiment, it is cut into a connecting line with a length of 124mm, and the length of the full stripping section is 2mm, and the length of the half stripping section is in the range of 2-10mm. , preferably the length of the half-stripped section is 3mm, and the distance between the half-stripped section and the end of the connecting wire is 38 mm.

[0027] The front part of the connecting wire is fully stripped to form a full-stripping section, and the part near the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com