Pretreatment method of polybrominated diphenyl ethers in environment solid matrix

A polybrominated diphenyl ether and solid matrix technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of long extraction time, cumbersome extraction method steps, high energy consumption, etc. less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

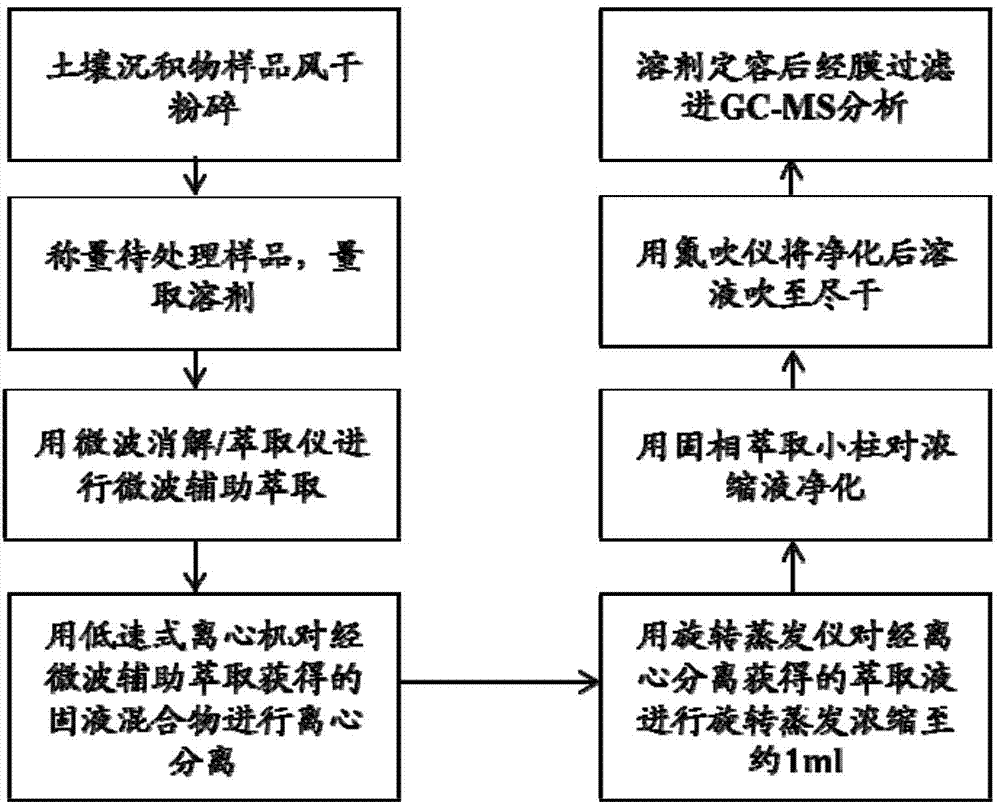

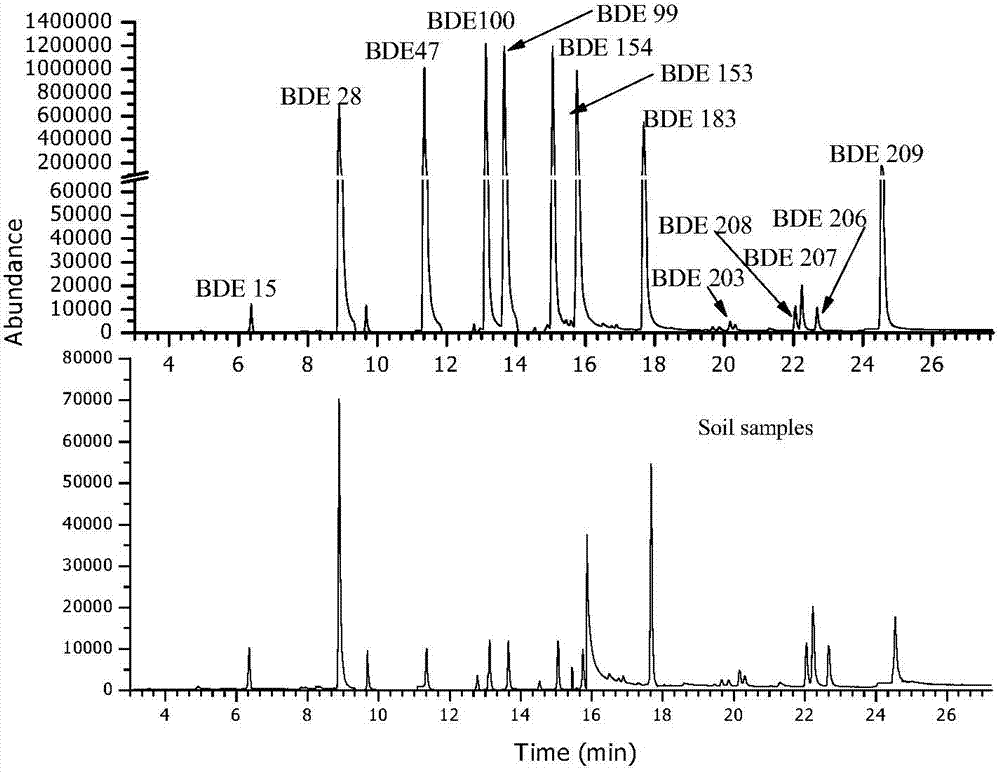

[0037] like figure 1 As shown, the microwave-assisted extraction of the present invention coupled with solid-phase purification technology analyzes the method for PBDEs in soil, comprising the following steps:

[0038] Step 1. Samples are air-dried and pulverized: the samples are wrapped in tinfoil, and the soil samples to be treated are freeze-dried using a vacuum freeze dryer, and then ground to a smaller particle size with a glass mortar; the freeze-drying temperature is -40 to -60 ℃, the drying time is 24±1h, and the minimum particle size is less than 2mm.

[0039] In this embodiment, the soil sample to be treated is specifically Taizhou farmland soil. During actual operation, the freeze-drying temperature is -50°C, and the drying time is 24 hours. After being air-dried and ground, pass through a 2mm sieve for later use.

[0040] Step 2, microwave-assisted extraction of the sample to be processed, the extraction process is as follows:

[0041] 201. Weigh the soil sampl...

Embodiment 2

[0061] The difference between this example and Example 1 is that the sediment sample to be treated in Step 1 is specifically Taihu Lake bottom mud.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com