On-line large slewing bearing residual life prediction method based on multi-dimensional data drive

A technology of slewing bearings and multi-dimensional data, applied in the direction of mechanical bearing testing, etc., can solve the problems of few IMF filtering, selection of reconstructed signals, effect dependence, and inability to obtain optimal selection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] An embodiment of the present invention will be described in detail below.

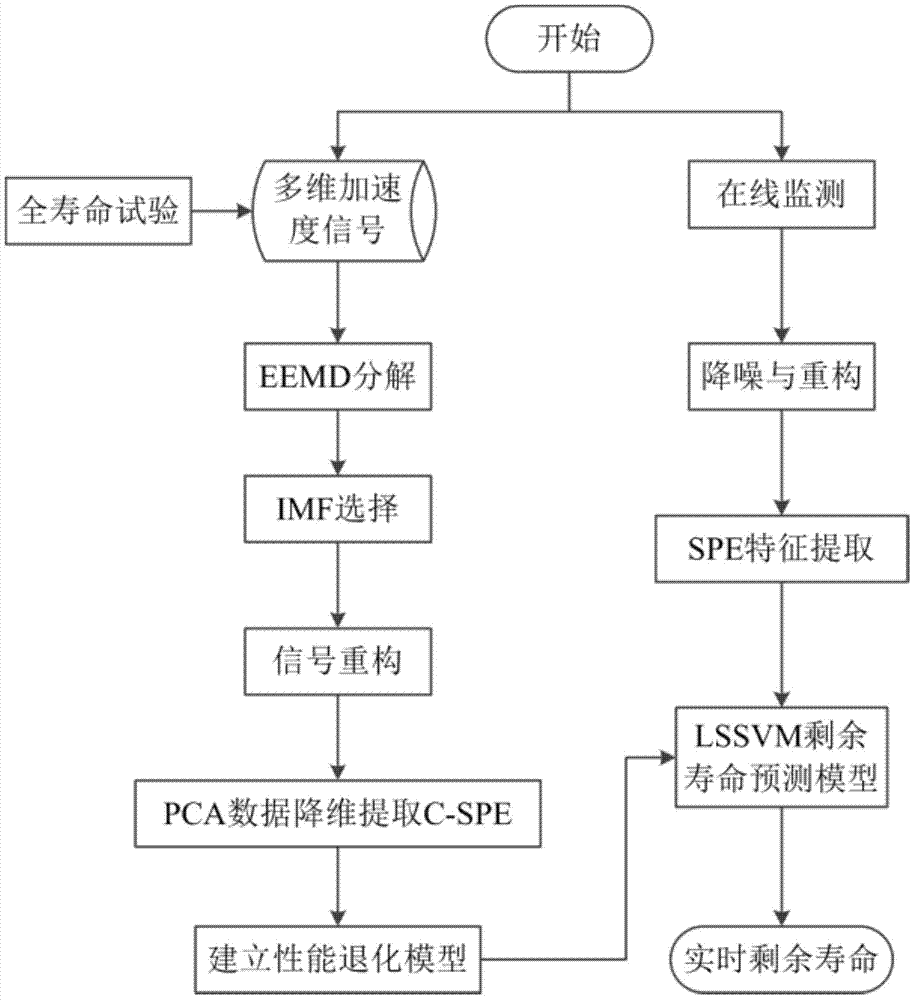

[0043] Such as figure 1 As shown, this embodiment describes an online prediction method for the remaining life of large slewing bearings driven by multidimensional data, including the following steps:

[0044] 1) Obtain multi-dimensional acceleration signals. In this example, the multi-dimensional vibration acceleration signal of the slewing bearing in its entire life a 1 ,a 2 ,a 3 ,a 4 It is obtained through a full-load fatigue life test on a brand-new QWA710.25 slewing bearing of a certain company. During the test, the slewing bearing is subjected to a constant 100% design load, and the speed is 4r / min. The four sets of acceleration sensors on the inside collect the relative axial and radial vibrations of the inner and outer ring raceways of the slewing bearing respectively. The sampling frequency is 2kHz, and the sample length is 67584 points. The measured original signals are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com