Cylinder face photometric measurement device

A technology of photometric measurement and cylindrical surface, which is applied in the field of cylindrical photometric measurement devices, can solve the problems of high manufacturing cost of parabolic reflectors, harsh measurement environment requirements, and difficulty in popularization and use, and achieve low cost, simple and low equipment, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

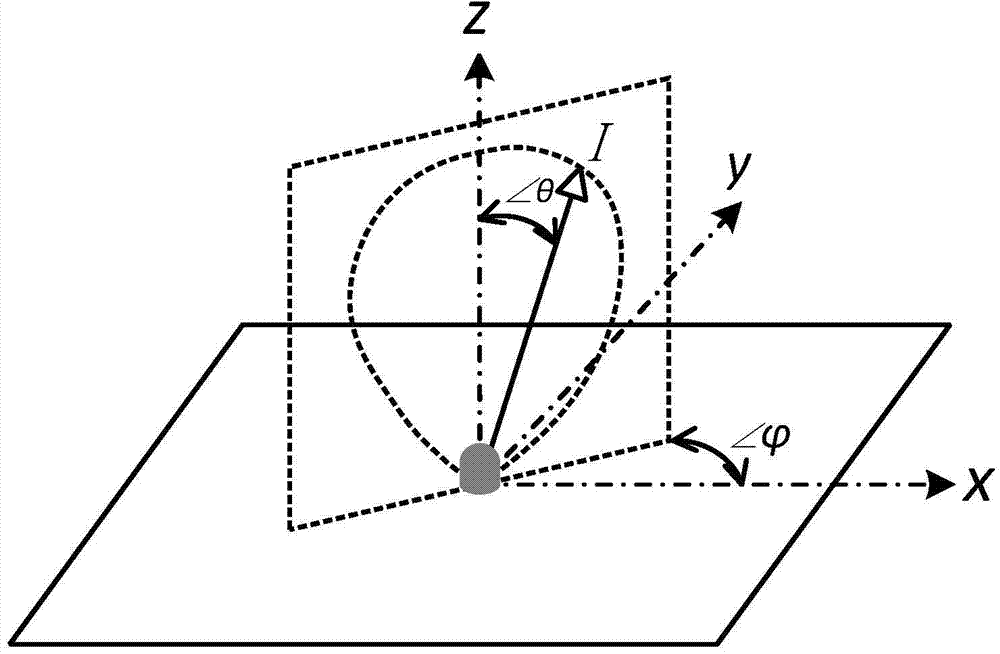

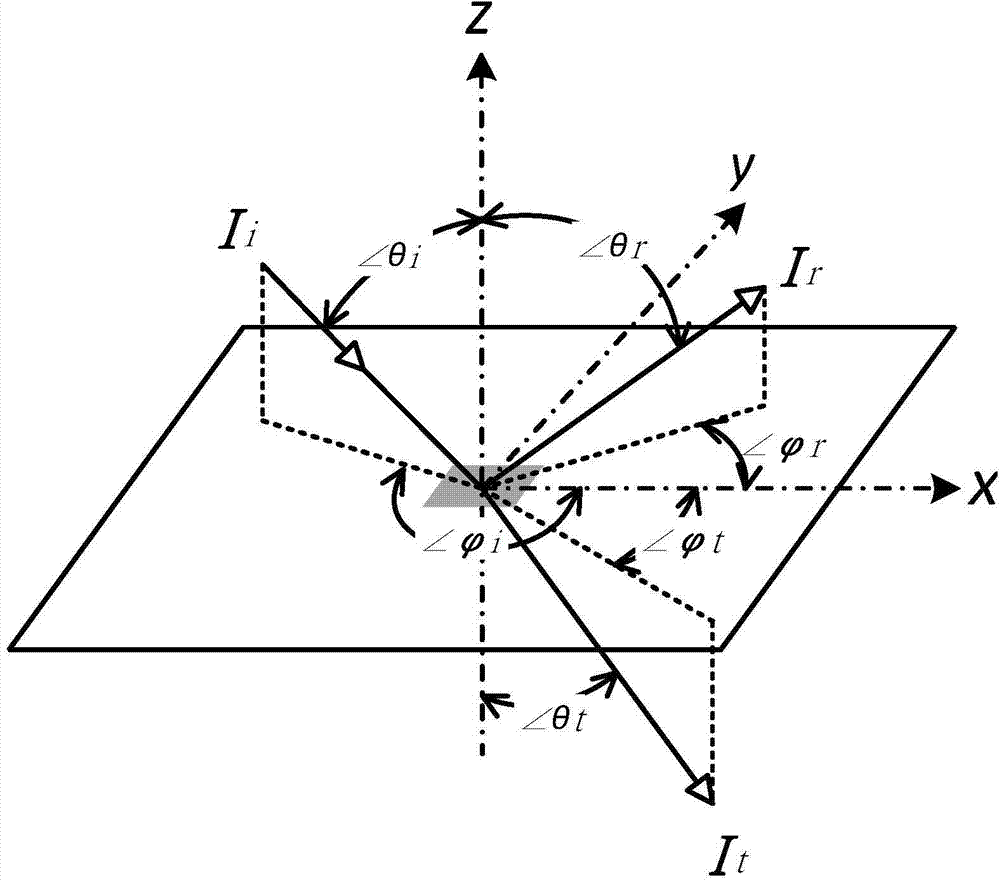

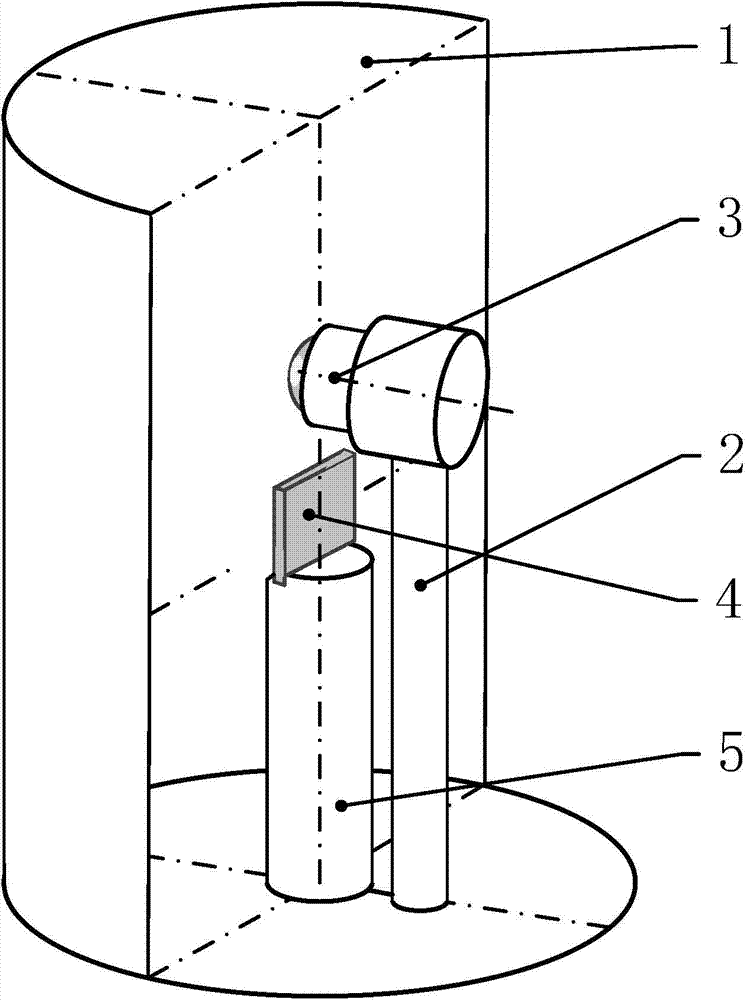

[0058] Such as image 3 As shown, the cylindrical light screen 1 is a cylindrical surface with an arc-shaped cross section, and the radius of the cylindrical surface is R; the stage 4 is located at the midpoint of the axis of the cylindrical light screen 1, which is recorded as the sample point S; The center C is located on the midpoint of the axis of the cylindrical light screen 1 and the distance from the sample point S is d, and the optical axis of the camera is perpendicular to the cylindrical axis and faces the light screen. Taking the sample point S as the coordinate origin, establish as Figure 4 The world coordinate system S shown xyz -(x,y,z), while establishing a sample spherical coordinate system S ρ -(ρ,,). The position of the optical center C of the fisheye camera 3 in the world coordinate system is S xyz -(0,0,d), with point C as the origin, establish the camera ball coordinate system C rαβ -(r,α,β). Based on the center point P of the captured photo, an ima...

Embodiment 2

[0074] Such as Figure 5 As shown, the optical screen 1 is a cylindrical surface with a circular cross-section, and the radius of the cylindrical surface is R; the stage 4 is located at the midpoint of the axis of the cylindrical optical screen 1, which is recorded as the sample point S; The distance between the midpoint of the axis of the cylindrical light screen 1 and the sample point S is d, and the optical axis of the camera coincides with the axis of the cylindrical light screen 1 . Taking the sample point S as the coordinate origin, establish as Figure 4 The world coordinate system S shown xyz -(x,y,z), while establishing a sample spherical coordinate system S ρ -(ρ,,). The position of fisheye camera 3 optical center C in the world coordinate system is S xyz -(0,0,d), with point C as the origin, establish the camera ball coordinate system C rαβ -(r,α,β). Based on the center point P of the captured photo, an image coordinate system P is established uv -(u,v), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com