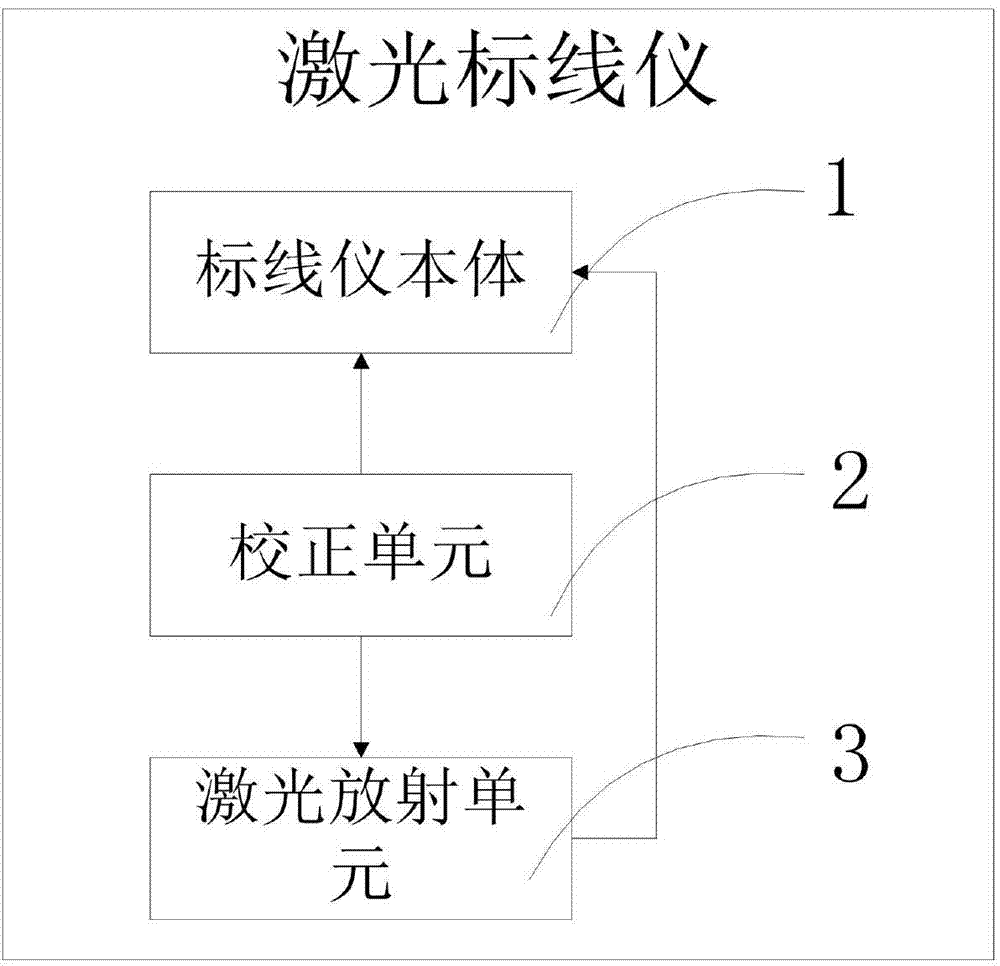

Laser marking instrument with automatic correcting function

A laser marking instrument and the technology of the line marking instrument, applied in the field of the line marking instrument, can solve the problems of precision measurement defects, lack of automatic correction function of the laser marking instrument, etc., and achieve the goal of reducing memory space, increasing practicability, and improving measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

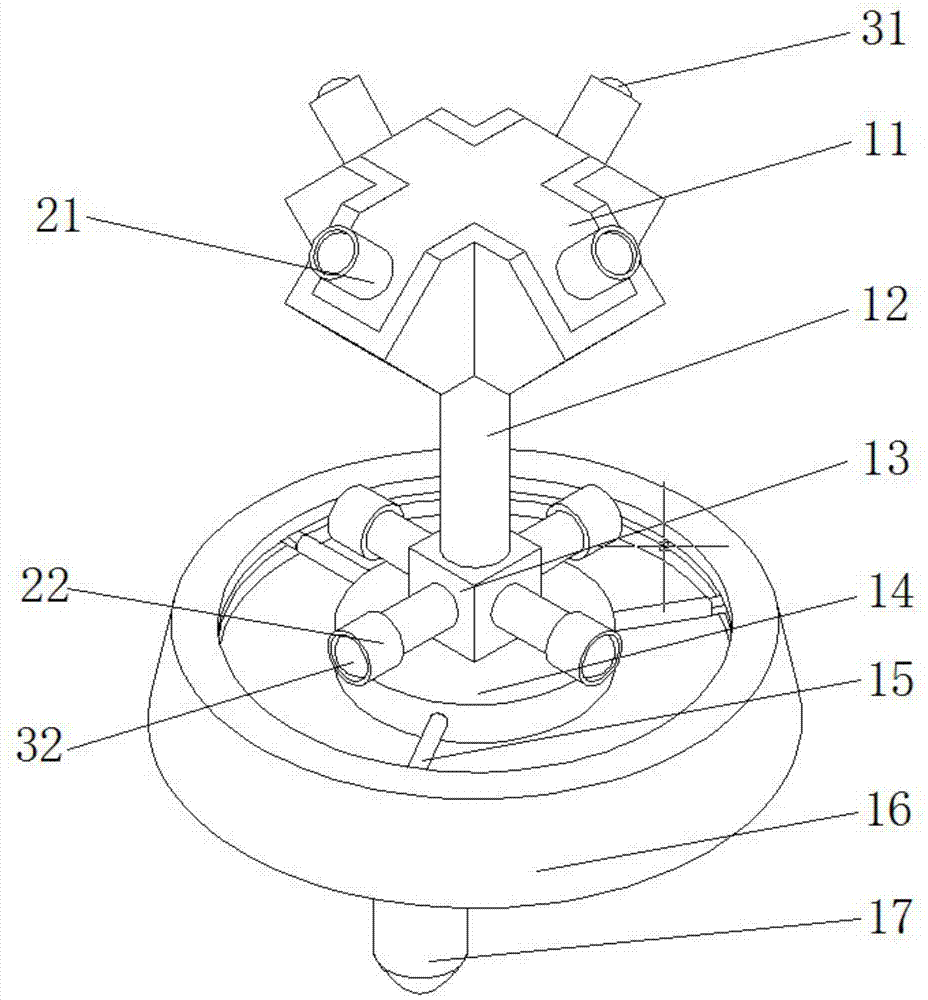

Embodiment 1

[0059] The difference between this embodiment and the above-mentioned laser marking instrument is that, as shown in Figure 2, it is a schematic structural diagram of Embodiment 1 of the multi-line laser marking instrument of the present invention; the outer surface of the telescopic support 12 There is a layer of threads on the surface, and the vertical bearing box 11 and the horizontal bearing box 13 are respectively fixed on the two ends of the telescopic support 12, and are all connected by threads. If necessary, change the vertical bearing box 11 and the horizontal bearing box 13 height, it is only necessary to rotate the vertical bearing box 11 and the horizontal bearing box 13, and the screw connection is relatively firm, so that the vertical bearing box 11 and the horizontal bearing box 13 will not slide suddenly and cause damage The phenomenon of the internal structure of the vertical bearing box 11 or the horizontal bearing box 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com